Page 6 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 6

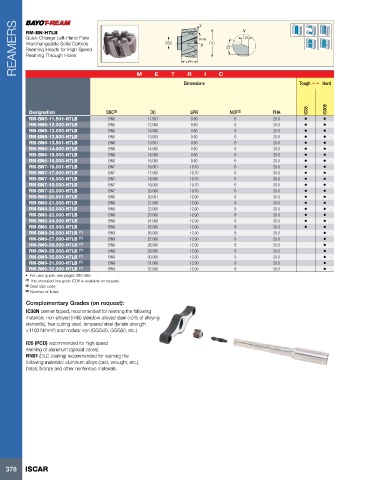

REAMERS RM-BN-H7LB SSC LPR V FHA DC 25° 1.07

V

Quick Change Left-Hand Flute

Interchangeable Solid Carbide

Reaming Heads for High Speed

Reaming Through Holes

E

M

T

R

Dimensions I C Tough 1 Hard

Designation SSC (2) DC LPR NOF (3) FHA IC08 IC908

RM-BN5-11.501-H7LB BN5 11.501 9.50 6 20.0 • •

RM-BN5-12.000-H7LB BN5 12.000 9.50 6 20.0 • •

RM-BN5-13.000-H7LB BN5 13.000 9.50 6 20.0 • •

RM-BN5-13.500-H7LB BN5 13.500 9.50 6 20.0 • •

RM-BN6-13.501-H7LB BN6 13.501 9.50 6 20.0 • •

RM-BN6-14.000-H7LB BN6 14.000 9.50 6 20.0 • •

RM-BN6-15.000-H7LB BN6 15.000 9.50 6 20.0 • •

RM-BN6-16.000-H7LB BN6 16.000 9.50 6 20.0 • •

RM-BN7-16.001-H7LB BN7 16.001 10.70 6 20.0 • •

RM-BN7-17.000-H7LB BN7 17.000 10.70 6 20.0 • •

RM-BN7-18.000-H7LB BN7 18.000 10.70 6 20.0 • •

RM-BN7-19.000-H7LB BN7 19.000 10.70 6 20.0 • •

RM-BN7-20.000-H7LB BN7 20.000 10.70 6 20.0 • •

RM-BN8-20.001-H7LB BN8 20.001 12.90 8 20.0 • •

RM-BN8-21.000-H7LB BN8 21.000 12.90 8 20.0 • •

RM-BN8-22.000-H7LB BN8 22.000 12.90 8 20.0 • •

RM-BN8-23.000-H7LB BN8 23.000 12.90 8 20.0 • •

RM-BN8-24.000-H7LB BN8 24.000 12.90 8 20.0 • •

RM-BN8-25.000-H7LB BN8 25.000 12.90 8 20.0 • •

RM-BN9-26.000-H7LB (1) BN9 26.000 12.90 8 20.0 •

RM-BN9-27.000-H7LB (1) BN9 27.000 12.90 8 20.0 •

RM-BN9-28.000-H7LB (1) BN9 28.000 12.90 8 20.0 •

RM-BN9-29.000-H7LB (1) BN9 29.000 12.90 8 20.0 •

RM-BN9-30.000-H7LB (1) BN9 30.000 12.90 8 20.0 •

RM-BN9-31.000-H7LB (1) BN9 31.000 12.90 8 20.0 •

RM-BN9-32.000-H7LB (1) BN9 32.000 12.90 8 20.0 •

• For user guide, see pages 380-385

(1) The uncoated fine grain IC08 is available on request

(2) Seat size code

(3) Number of flutes

Complementary Grades (on request):

IC30N cermet tipped, recommended for reaming the following

materials: non-alloyed (mild) steel,low alloyed steel (<5% of alloying

elements), free cutting steel, tempered steel (tensile strength

<1100 N/mm ) and nodular iron (GGG40, GGG60, etc.)

2

ID5 (PCD) recommended for high speed

reaming of aluminum (special cases).

RN01 (DLC coating) recommended for reaming the

following materials: aluminum alloys (cast, wrought, etc.),

brass, bronze and other nonferrous materials.

378 ISCAR