Page 14 - ISCAR's solutions for Heavy Machining 2022

P. 14

Heavy Machining

HEAVY

T

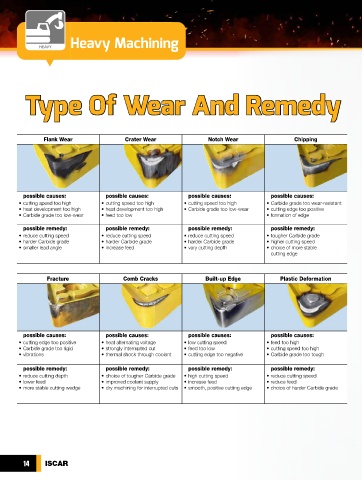

Type Of Wear And Remedyype Of Wear And Remedy

Flank Wear Crater Wear Notch Wear Chipping

possible causes: possible causes: possible causes: possible causes:

• cutting speed too high • cutting speed too high • cutting speed too high • Carbide grade too wear-resistant

• heat development too high • heat development too high • Carbide grade too low-wear • cutting edge too positive

• Carbide grade too low-wear • feed too low • formation of edge

possible remedy: possible remedy: possible remedy: possible remedy:

• reduce cutting speed • reduce cutting speed • reduce cutting speed • tougher Carbide grade

• harder Carbide grade • harder Carbide grade • harder Carbide grade • higher cutting speed

• smaller lead angle • increase feed • vary cutting depth • choice of more stable

cutting edge

Fracture Comb Cracks Built-up Edge Plastic Deformation

possible causes: possible causes: possible causes: possible causes:

• cutting edge too positive • heat alternating voltage • low cutting speed • feed too high

• Carbide grade too rigid • strongly interrupted cut • feed too low • cutting speed too high

• vibrations • thermal shock through coolant • cutting edge too negative • Carbide grade too tough

possible remedy: possible remedy: possible remedy: possible remedy:

• reduce cutting depth • choice of tougher Carbide grade • high cutting speed • reduce cutting speed

• lower feed • improved coolant supply • increase feed • reduce feed

• more stable cutting wedge • dry machining for interrupted cuts • smooth, positive cutting edge • choice of harder Carbide grade

14 ISCAR