The Impact of Additive Manufacturing on the Evolution of Metalworking Tools

In recent years, additive manufacturing (AM), commonly known as 3D printing, has emerged as a transformative force across various industries, including metalworking. This technology, characterized by its layer-by-layer material addition process, contrasts with traditional subtractive manufacturing methods and has introduced a new paradigm in the design and production of metalworking tools. ISCAR’s additive manufacturing is affecting the evolution of metalworking tools, highlighting the benefits, challenges, and future potential of this innovative approach to assure customers receive tools to increase productivity and metalworking efficiency.

Enhanced Design Flexibility

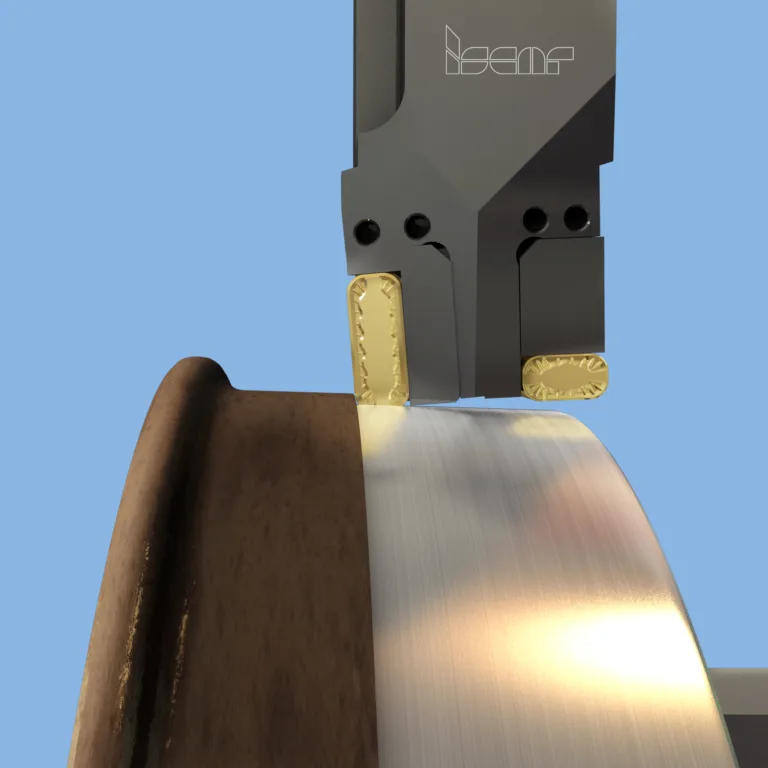

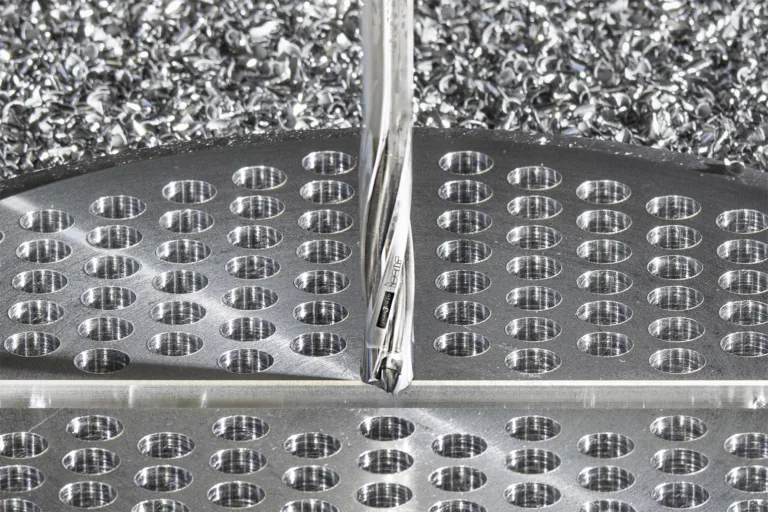

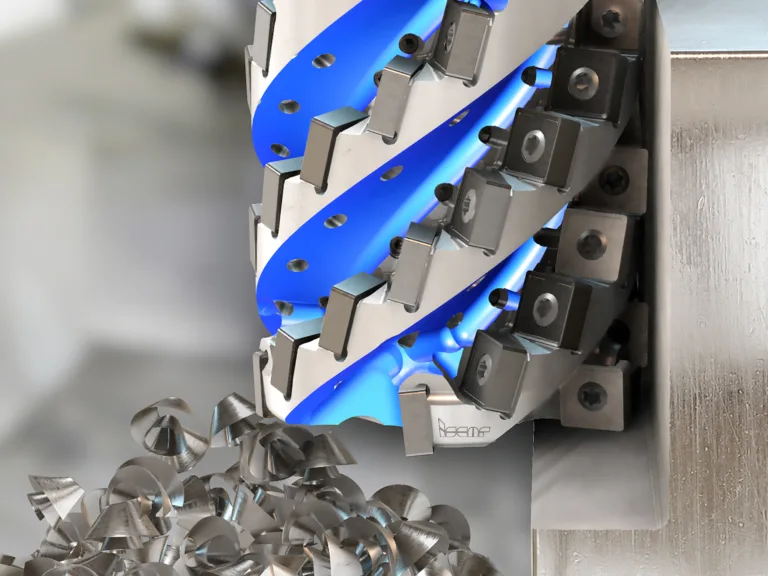

One of the most significant impacts of additive manufacturing on metalworking tools is the enhanced design flexibility it offers. Traditional manufacturing methods often impose limitations on tool design due to constraints related to machining processes and material removal. In contrast, AM enables the creation of complex geometries and intricate internal structures that were previously impossible or cost-prohibitive to achieve. Additive manufacturing technologies enable maximum use of computational fluid dynamics for optimizing the profile of inner channels to ensure efficient pinpointed coolant through the cutter body. Traditional machining processes have limitations in shaping the channels, while AM capabilities provide endless options. This newfound design freedom allows ISCAR’s prolific engineers to optimize tool performance, leading to improved efficiency and functionality. Complex drilling, milling, grooving, and turning tools are now redefined to provide a winning cutting edge for ISCAR’s customers.

Customization and Rapid Prototyping

Additive manufacturing facilitates the customization of metalworking tools to meet ISCAR’s customers’ specific application requirements. With AM, ISCAR can quickly produce prototypes and iterate designs based on feedback, significantly reducing development time. This rapid prototyping capability is particularly advantageous in industries where tool performance is critical, such as aerospace and automotive sectors. Customization also extends to the production of small-batch or one-off tools, offering solutions tailored to unique machining challenges.

Material Innovation

ISCAR’s evolution of producing metalworking tools through additive manufacturing is closely linked to advancements in material science. ISCAR’s AM processes have expanded the range of materials available for tool production, including high-performance alloys and composites. These materials can enhance tool properties such as hardness, wear resistance, and heat tolerance, resulting in longer tool life and improved machining performance. Furthermore, the ability to blend materials within a single tool allows for the creation of multi-functional tools with specific properties at different sections.

Cost and Waste Reduction

ISCAR’s ongoing development of additive manufacturing has the potential to reduce costs and material waste in the production of metalworking tools. Traditional manufacturing often involves significant material removal, leading to waste and increased production costs. AM, on the other hand, adds material only where needed, minimizing waste and optimizing material usage. While the initial cost of AM equipment and materials can be high, the reduction in waste and the ability to produce complex designs without additional tooling can result in long-term cost savings. This initiative creates a stronger footprint for ISCAR’s efforts related to sustainability and the reduction of machining power.

Challenges and Considerations

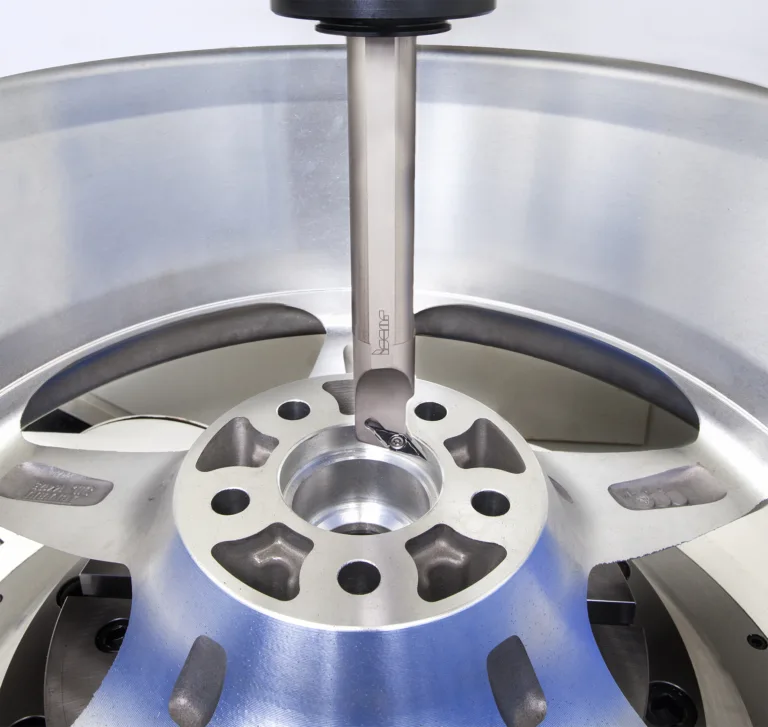

Despite its many advantages, the integration of additive manufacturing into metalworking tool production is not without challenges. One major consideration is the quality and reliability of AM-produced tools. ISCAR ensures consistent material properties and surface finishes that require careful process control and post-processing techniques. Additionally, the limited size of build chambers in some AM machines may restrict the dimensions of tools that can be produced, necessitating hybrid approaches combining AM with traditional methods. Additive manufacturing is an effective way to reduce the weight of large and heavy tools, particularly rotating tools (see attached photo). ISCAR designs and produces special tools that offer green energy with several advantages:

- Power Saving: Less power is needed for starting and breaking the tool spindle, resulting in cost savings.

- Reduced Spindle Service: The design leads to less wear and tear on the spindle, further reducing costs.

- Easier Handling: With less weight compared to all competitors, our tools are easier for workers to handle on ZOLLER measuring units and during machine operations.

- Innovative Design: This approach allows ISCAR to offer tools with coolant channels that would be very complicated or even impossible to achieve with a Monoblock holder.

Outlook

ISCAR sees the future of metalworking tools in the context of additive manufacturing as promising. As AM technology continues to advance, we can expect further improvements in material properties, production speed, and cost-effectiveness. The development of larger and more capable AM machines will expand the possibilities for tool production, while ongoing research into new materials and processes will enhance tool performance and durability.

ISCAR’s tools produced with additive manufacturing are reshaping the landscape of metalworking tools by introducing new design possibilities, enabling customization, and promoting material innovation. While challenges remain, the benefits of AM are driving its adoption and integration into the metalworking industry. ISCAR continues to explore and leverage these advancements, the evolution of metalworking tools will undoubtedly lead to more efficient and effective machining solutions.