ISCAR’s Cutting-Edge Solutions for Machining Automotive Turbocharged Engines

In the rapidly evolving automotive industry, turbocharged engines have become increasingly prevalent due to their ability to enhance engine performance, improve fuel efficiency, and reduce emissions. However, machining the high-precision components of a turbocharged engine presents significant challenges. ISCAR offers state-of-the-art solutions specifically designed to address these challenges, ensuring superior performance, efficiency, and cost-effectiveness.

Turbocharged engines typically require the machining of complex geometries and hard-to-cut materials such as titanium alloys, heat-resistant stainless steel, and high-temperature alloys. These materials are chosen for their durability and capacity to withstand extreme conditions but are notoriously difficult to machine due to their hardness and propensity for rapid tool wear. Achieving the high levels of precision required for turbo engine components is crucial for optimal engine performance.

Engine downsizing is a prevailing trend in the automotive industry, with turbochargers now commonly found in both large diesel and gasoline engines. Turbochargers can significantly boost an engine’s horsepower without a substantial increase in weight, providing high performance and additional benefits for modern vehicles. However, turbochargers present challenges for original equipment manufacturers (OEMs), as they must endure extreme operating conditions, very high temperatures, and high-speed revolutions per minute (rpm). These demands drive OEMs to explore new materials and technologies in real-time.

ISCAR’s extensive global industry experience positions the company at the forefront of providing higher productivity, profitability, and performance gains. In the field of turbochargers, ISCAR presents innovative solutions and stable processes for turbocharger-related components. ISCAR views OEMs as high-priority customers and is committed to building long-term partnerships. The company’s goals include recommending efficient and economical solutions, delivering high-quality products, and providing long-lasting support.

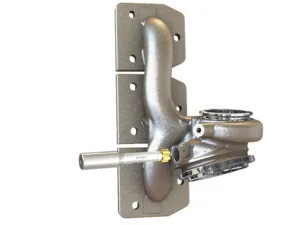

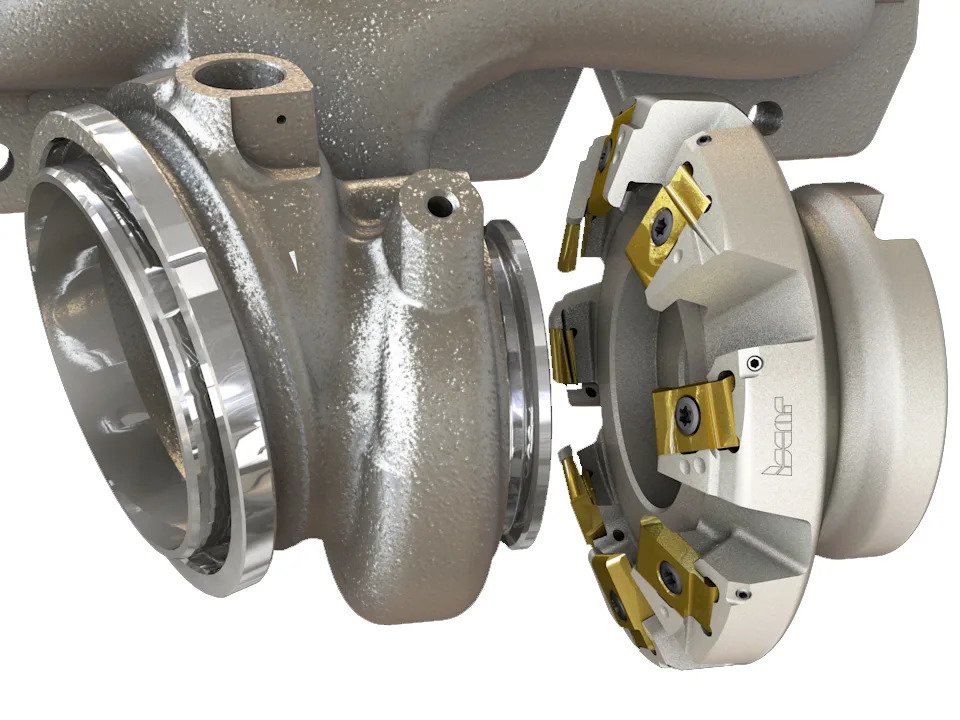

ISCAR has developed a comprehensive range of cutting tools and solutions specifically designed for the challenges of machining automotive turbo charged engines. These solutions focus on enhancing productivity, extending tool life, and achieving exceptional surface finishes, all while maintaining cost-efficiency. Engineered for high-feed and high-efficiency milling, ISCAR’s indexable milling cutters are ideal for both roughing and finishing operations (fig. 1 and fig. 2). Their robust design ensures stability and precision, even in demanding machining conditions. The use of advanced geometries and coatings helps mitigate issues related to high temperatures and tool wear.

Designed for machining hard materials, ISCAR’s endmills offer exceptional durability and precision. Available in various geometries and coatings, ISCAR’s solid carbide endmills cater to the specific needs of turbocharged engine component manufacturing, providing solutions for high-speed and high-accuracy applications.

ISCAR offers a wide range of turning optimized for machining high-temperature alloys and other challenging materials. These inserts are designed to minimize tool wear and provide excellent chip control, ensuring smooth and efficient machining processes. The advanced insert geometries allow for reduced cutting forces, contributing to improved tool life and surface finish.

Grooving operations are critical in the manufacturing of turbocharged engine components, where precision and surface quality are paramount. ISCAR’s grooving tools are designed to handle the rigorous demands of machining hard-to-cut materials and complex geometries.

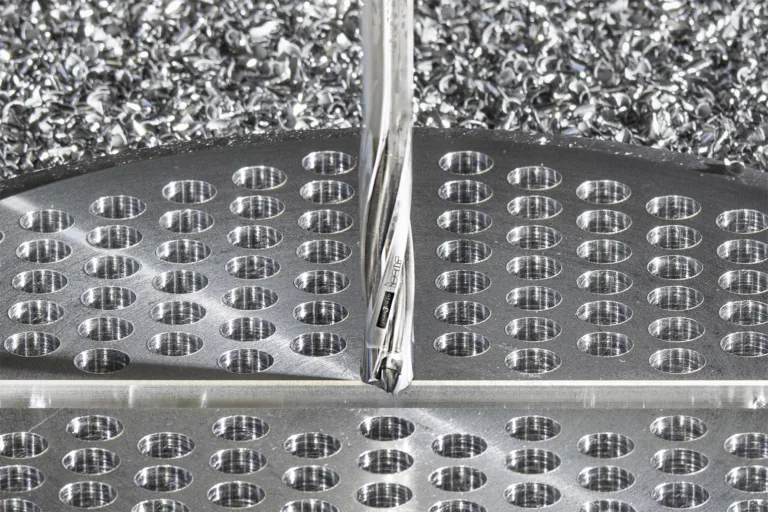

ISCAR offers a wide range of indexable grooving inserts tailored for machining high-temperature alloys and other challenging materials (fig.3). These inserts are engineered to deliver exceptional wear resistance and superior chip control. The inserts are available in various geometries and cutting edges, optimized for different grooving applications, ensuring smooth and efficient material removal.

ISCAR’s grooving holders are designed to provide maximum stability and precision during machining. The holders feature robust clamping mechanisms to secure the inserts firmly, reducing vibrations and enhancing tool life. The innovative design of these holders allows for easy insert replacement, minimizing downtime and improving overall productivity.

ISCAR utilizes cutting-edge coatings on its tools to enhance performance. These coatings provide superior wear resistance, reduce friction, and allow for higher cutting speeds, thereby increasing productivity and tool longevity. Coated tools also contribute to improved surface finishes, which are critical for the performance of turbocharged engine components. Nano-layered coatings, such as TiAlN and AlTiN, provide enhanced thermal stability and oxidation resistance, essential for high-temperature applications.

Recognizing that each turbocharged engine component may have unique machining requirements, ISCAR offers customized solutions (fig.4). ISCAR’s engineering teams collaborate closely with clients to develop tools and machining strategies tailored to specific needs, ensuring optimal results and efficiency. This approach allows for the integration of advanced tool paths and machining parameters, maximizing performance.

ISCAR is at the forefront of digital transformation in manufacturing. The company’s smart tools and digital solutions enable real-time monitoring and data analysis, allowing manufacturers to optimize machining processes, reduce downtime, and increase overall efficiency. By integrating Industry 4.0 technologies, such as IoT-enabled tool management systems and predictive maintenance platforms, ISCAR helps clients stay competitive in a rapidly evolving market.

Choosing ISCAR’s solutions for machining automotive turbo engines provides several key advantages: With innovative tools and technologies, machining processes become faster and more efficient, reducing cycle times and increasing productivity. Longer tool life and improved machining performance lead to lower overall manufacturing costs, providing significant economic benefits.

ISCAR’s solutions ensure high-quality finishes and precise machining, essential for the demanding specifications of turbo engine components. Efficient machining practices result in less waste and reduced energy consumption, contributing to more sustainable manufacturing processes.

In the competitive automotive industry, ISCAR stands out as a key partner, offering cutting-edge solutions for machining turbo engines. By addressing the unique challenges of machining advanced materials and complex geometries, ISCAR not only meets the industry’s current demands but also paves the way for future advancements. With a commitment to quality, efficiency, and innovation, ISCAR continues to drive the machining industry forward, helping manufacturers achieve new levels of performance and success.