Advanced Machining of Lightweight Engineering Materials with ISCAR Tools

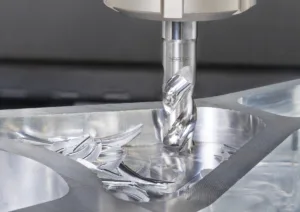

In today’s manufacturing landscape, industries such as aerospace, space, automotive, and electronics are driving a rapid increase in the demand for lightweight engineering materials. These materials, including aluminum alloys, titanium, and composites, are favored for their excellent strength-to-weight ratios, corrosion resistance, and thermal performance. However, their unique properties also present machining challenges. Lightweight structures are increasingly incorporating polymeric materials, which, due to their low density, inherently lack stiffness. To counter this, various types of reinforcements are used, yet these are often hard and abrasive, turning otherwise easy-to-machine materials into ones that pose significant challenges for conventional machining operations. Alongside traditional machining, several technologies have been developed to perform essential cutting and drilling operations, even when employing modern near-net-shape processing. ISCAR has developed a range of innovative tools and techniques to address these challenges and optimize the machining process for lightweight materials. ISCAR’s tools enhance both productivity and precision (Fig. 1). Lightweight materials, while advantageous for their application-specific properties, pose several machining challenges due to their unique properties. Materials like titanium, known for their high ductility and toughness, can be particularly difficult to cut, often resulting in rapid tool wear and suboptimal surface finishes. Aluminum’s high thermal conductivity poses another challenge, as it can lead to excessive heat build-up in cutting tools, adversely affecting both tool life and the quality of the workpiece. Additionally, composite materials, with their abrasive nature, can accelerate tool degradation and pose risks of delamination, further complicating the machining process.

In the realm of material science, significant research has been dedicated to developing lightweight engineering materials that boast high specific modulus, strength, and stiffness, even under elevated temperatures, while also resisting creep, fatigue, and wear. Tailor-made for specific applications, these advanced materials include Metal Matrix Composites (MMCs), such as dispersion-strengthened aluminum matrix composites reinforced with silicon carbide particles (Al/SiCp). These composites enhance the thermal properties of aluminum matrices and are utilized in industries ranging from aerospace to automotive. Despite their advantages, MMCs, particularly silicon carbide reinforced aluminum alloys, present machining challenges due to their diverse material properties.

ISCAR has engineered a range of cutting tools specifically designed to address these challenges, focusing on tool material, geometry, and coating technology.

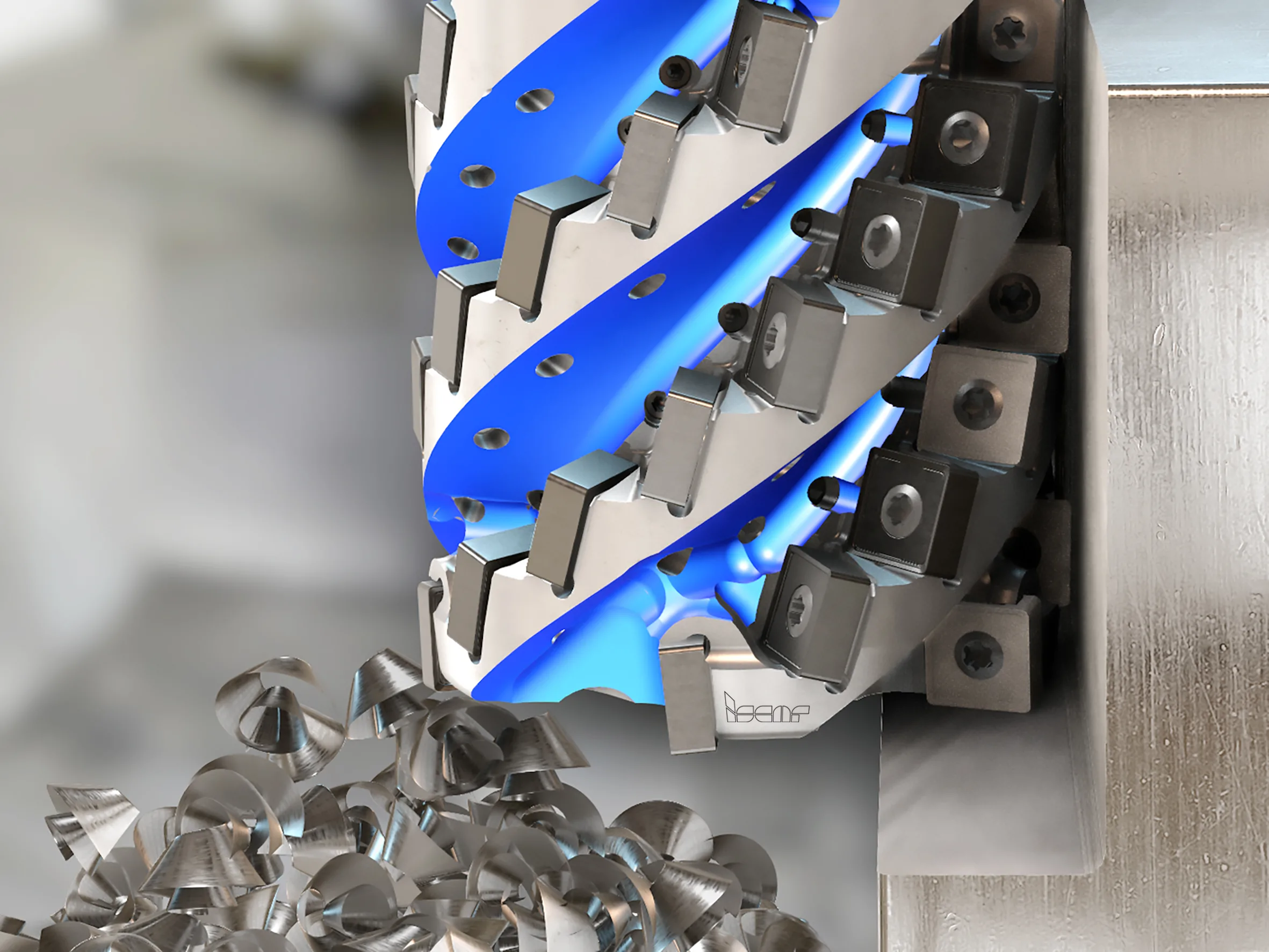

1. Optimized Tool Geometries: ISCAR offers tools with specialized geometries that reduce cutting forces and enhance chip evacuation. For example, their QUICK-X-FLUTE range features indexable inserts with specially designed cutting edges that provide smooth cutting action and minimize vibration when machining titanium (Fig. 2).

2. Advanced Coatings: The application of advanced coatings, such as TiAlN and diamond-like carbon (DLC), increases tool hardness and abrasion resistance. ISCAR’s SUMO TEC coating technology enhances tool life and performance when machining high-temperature alloys and composites.

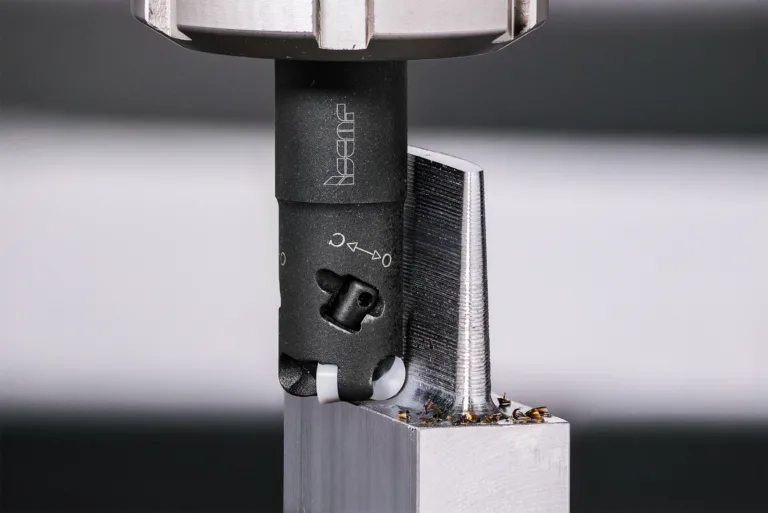

3. High-Performance Milling Cutters: ISCAR’s HELIALU indexable shell mills, MULTI-MASTER tools with exchangeable solid carbide heads, and CHATTERFREE solid end mills (Fig. 3) are designed for high-speed milling of aluminum alloys, offering excellent surface finish and prolonged tool life. Their unique design minimizes chatter, a common issue when machining thin-walled components.

4. Specialized Inserts: For turning operations, ISCAR provides carbide inserts with rake faces and chip breakers tailored for lightweight materials (Fig. 4). These inserts ensure efficient chip control and reduce heat generation, thus enhancing both tool life and workpiece quality.

ISCAR’s tooling solutions are complemented by advanced machining techniques that further optimize the process:

1. High-Speed Machining (HSM): Utilizing ISCAR’s tools designed for high-speed applications allows manufacturers to increase productivity by reducing cycle times while maintaining precision and surface integrity.

2. Minimum Quantity Lubrication (MQL): ISCAR tools are compatible with MQL systems, which significantly reduce coolant use while providing adequate lubrication and cooling, essential for machining materials with low thermal conductivity like titanium.

3. Adaptive Machining Strategies: Implementing adaptive control strategies using ISCAR tools can help in maintaining consistent cutting conditions, improving tool life, and ensuring high-quality finishes on complex geometries.

The aerospace industry constantly seeks ways to improve fuel efficiency, performance, and sustainability. A key approach is the use of light metals such as aluminum and titanium alloys, which offer excellent strength-to-weight ratios. However, machining these materials presents unique challenges, including tool wear, heat generation, and surface quality. ISCAR provides advanced solutions specifically designed for the efficient machining of aerospace light metals. In addition, ISCAR realizes that the fast-growing space industry demands components that meet exacting standards for reliability, strength, and weight. As the sector expands, driven by innovations in satellite technology, space exploration, and commercial space travel, the need for advanced manufacturing techniques and materials intensifies. Machining parts for space applications involve working with challenging materials like titanium, aluminum alloys, and advanced composites.

Challenges in Machining Space Components

1. Material Properties: Space components often use materials with high strength-to-weight ratios, such as titanium and aluminum, which are difficult to machine due to their toughness and thermal properties.

2. Precision and Accuracy: The need for precise tolerances and exceptional surface finishes is critical in space applications, where even minor deviations can lead to significant performance issues.

3. Tool Wear and Longevity: High-performance materials can accelerate tool wear, necessitating the use of durable and efficient cutting tools.

Machining lightweight engineering materials requires a deep understanding of their properties and the challenges they present. ISCAR’s innovation and excellence provides cutting-edge tooling solutions that enable manufacturers to achieve superior results. Industries can enhance productivity, reduce costs, and maintain the high standards required in precision engineering. Whether it’s through optimized geometries, advanced coatings, or innovative machining strategies, ISCAR continues to lead the way in the efficient and effective machining of lightweight materials.