ISCAR Solutions for Heat Exchanger Manufacturing

Heat exchangers are essential components in thermal management systems, enabling efficient transfer of heat between fluids across a solid barrier. Commonly found in industries such as automotive, aerospace, power generation, and heavy industry, these components often present complex machining challenges due to their geometry, size, and material properties. ISCAR offers a comprehensive range of solutions tailored to meet the demanding manufacturing requirements of heat exchanger components.

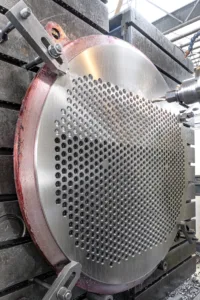

Precision Starts with Tube Sheet Preparation

Face milling is often the first operation on tube sheets, and surface quality here directly affects the performance of all following processes. ISCAR’s face mills combine robustness with efficiency. Key ISCAR tools, intended for face milling when tube sheet preparation, include a variety of cutters that mount the following indexable inserts:

- FFQ4 SOMT 0904: Square single-sided inserts with 4 cutting edges for high feed milling (HFM, “fast feed milling”).

- H1200 HXCU 0606: Double-sided hexagonal inserts with 12 cutting edges.

- IQ845: Square double-sided milling inserts with 8 cutting edges for general use. (Fig. 1)

- ONMU/ONHU 07…: Octagonal inserts with 16 helical righthand cutting edges for economical face milling.

Each tool has been developed with a specific use case in mind to maximize both productivity and surface finish.

Turning: Built for Heavy-Duty Applications

Turning in tube sheet machining often involves challenging materials and heavy cuts. ISCAR’s turning platforms are designed to ensure stability, chip control, and long tool life, even under demanding conditions. Highlighted turning tools include: • DOVE-IQ: Double-sided inserts with R3P double-sided 7°negative side flank 80° rhombic inserts for heavy turning of steel.

• CNMG-R3M: Double-sided 80°rhombic inserts, first choice for rough machining of stainless and low carbon steel (Fig.2).

• RCMX: Round 7° inserts with a positive flank and strong cutting edge for rough turning.

• LOMX: Tangential inserts with 4 cutting edges for high metal removal of up to 35 mm D.O.C. on steel.

These tools are purpose-built to handle the rigors of heavy-duty machining while maintaining dimensional accuracy and tool reliability.

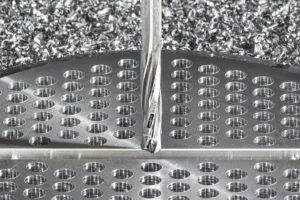

Drilling Tube Sheets and Baffles with Modular Precision

ISCAR’s SUMOCHAM line addresses the demands of precision drilling in tube sheets and baffles (Fig.3). With exchangeable heads and a quick-change self-clamping system, this platform minimizes downtime without compromising accuracy.

Key highlights:

- Diameter range: Ǿ4–32.9 mm (Ǿ 0.157–1.299″) in 0.1 mm (0.004″) increments

- 12 standard geometries covering the most used material groups.

• Drilling heads with self-centering chisel geometry design, eliminates the need for pilot holes up to 12×D. - High-performance IC908 submicron carbide with TiAlN coating.

- The drill body is designed to maximize flute volume and enhance chip evacuation efficiency.

- Polished flutes and drill body for improved chip evacuation.

The SUMOCHAM clamping pocket design provides a significantly high number of clamping indexes due to high precision and a deep contact area for insert mounting. The precise cylinder area on the clamping part increases rigidity and reduces internal stress. The rotation stopper planes on the tool are precision made to provide control on the drilling head position and support, which results in better tool performance and tool life. The SUMOCHAM line expands the boundaries of holemaking. This advancement opens new possibilities for using exchangeable drill heads in applications where only solid tools were previously considered, while enabling deep drilling up to 12×D without requiring a pilot hole.

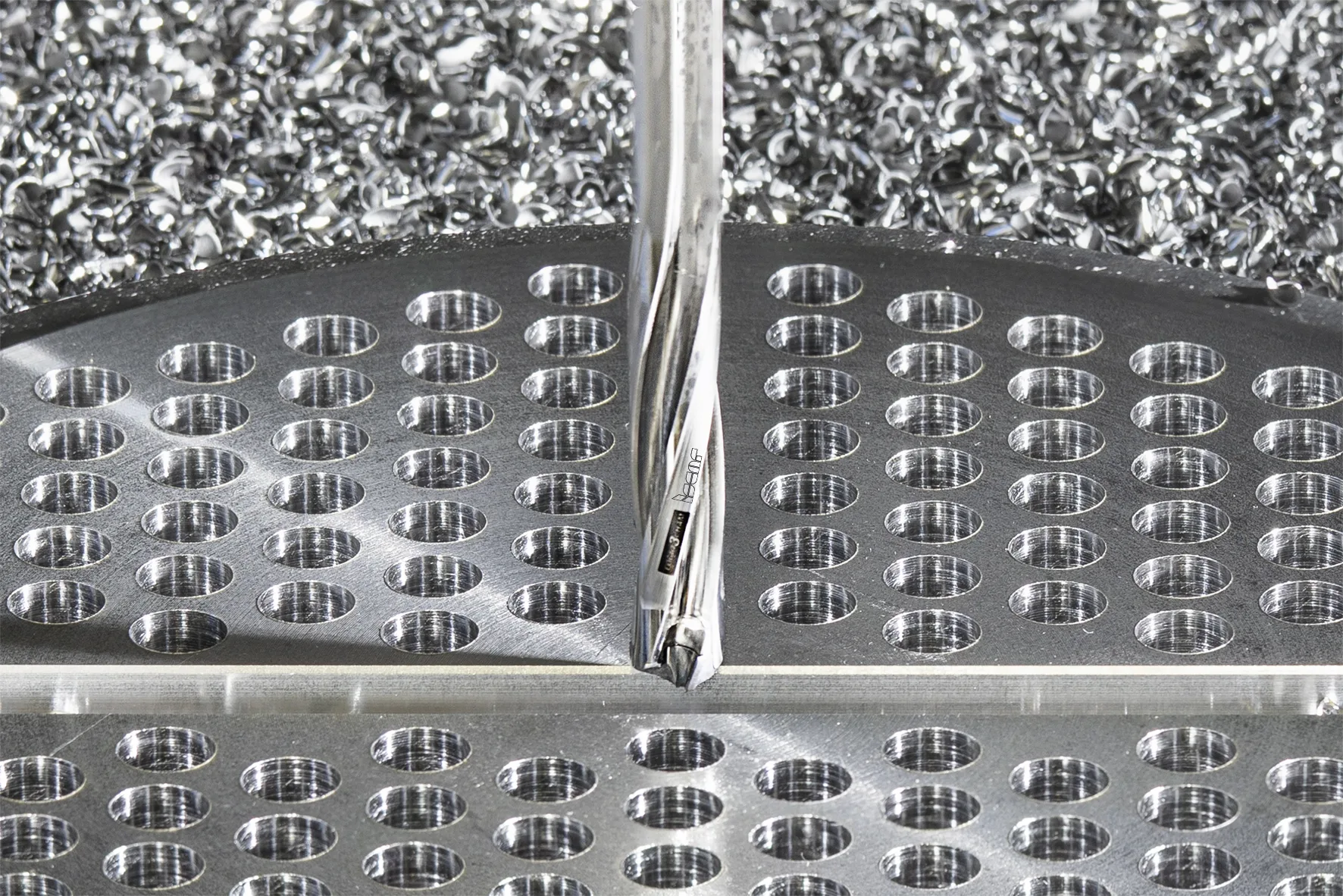

QUICK-3-CHAM: Advanced Exchangeable Heads

The most advanced level of productivity and cost efficiency comes with the QUICK-3-CHAM line, which includes three-flute drills with exchangeable drilling heads (Fig.4). These tools are designed to significantly increase productivity and reduce machining cycle time by up to 50% compared to conventional two-flute drills. QUICK-3-CHAM line designed mainly for ISO P (steel, cast steel, tool steel, ferritic and martensitic stainless steels) and ISO K (cast iron) materials, QUICK-3-CHAM heads integrate:

- Diameter range: Ǿ12–25.9 mm (Ǿ 0.472–1.020″) in 0.1 mm (0.004″) increments.

- Self-centering point geometry guarantees drilling process stability, good centering, and smooth penetration into the material capabilities.

- A patented, durable and precise chisel point combined with an appropriate gash angle successfully stands against a heavy cutting load.

- ISCAR’s patented concave cutting edges result in smooth and stable drilling, together with a wavy edge shape that significantly contributes to generating the optimal chip form and simplifying the chip evacuation process.

- The corner chamfer improves wear resistance and strengthens the cutting edge.

- Suitable for machining holes up to 10×D deep.

- Variable flute angle design provides durable tool structure to withstand high axial forces.

- ISCAR’s patented clamping pocket designed to withstand high machining cutting conditions, allowing easy and fast head indexing. Every feature of the QUICK-3-CHAM is designed for high metal removal rates, machining under tough conditions while offering reliability, repeatability, and precision.

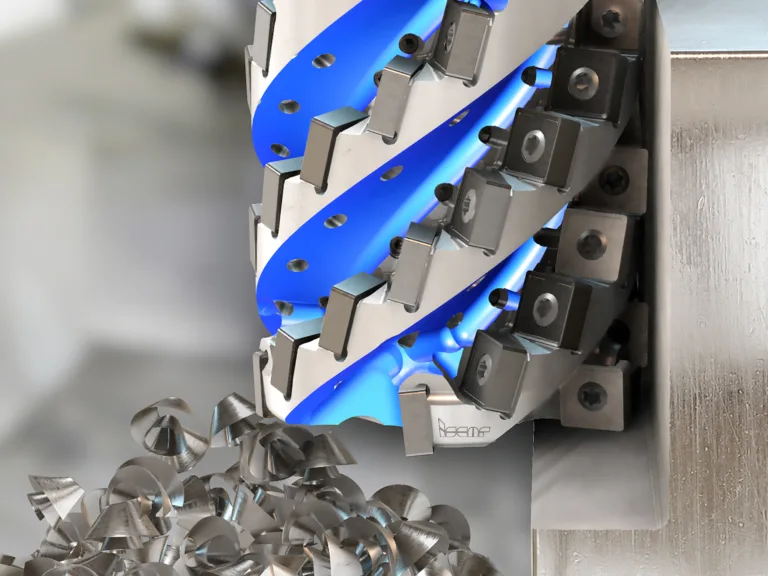

Deep Drilling: TRIDEEP and ISCAR-DEEP-DRILL Lines

Heat exchanger components often require holes beyond standard lengths. ISCAR meets this challenge with its TRI-DEEP and ISCAR-DEEP-DRILL lines.

The TRI-DEEP platform provides versatile solutions for all deep drilling methods that include gun drilling, single-tube (Fig. 5), and double-tube systems.

TRI-DEEP key offerings:

- Gun Drills: Capable of depths up to 25×D from 7.95 mm (0.313″) diameter.

- Single Tube System: Drilling diameters from 16–40 mm (0.63–1.575″) with external 4-start thread connection or internal single start thread connection.

- Double Tube System: Drilling diameters from 18.4–28 mm (0.724–1.102″) with an external 4-start thread connection.

ISCAR-DEEP-DRILL enhances this range with cartridge-equipped tools:

- Single Tube System: Diameter range 38–294 mm (1.496–11.575″), available in external and internal thread configurations.

- Double Tube System: Diameter range 38–184 mm (1.496–7.244″) with an external 4-start thread connection.

- Cartridges allow diameter expansion by up to 5 mm (0.197″).

These tools ensure stability and performance even at extreme drilling depths.

Grooving, Chamfering, and Reaming Finishing with Precision

In heat exchanger manufacturing, final operations like grooving, chamfering, and reaming are essential to ensuring reliable performance and tight sealing. These finishing steps must meet stringent dimensional and surface quality requirements to guarantee proper fit and function. For internal slitting and grooving, ISCAR’s MULTI-MASTER system offers a modular, high-precision solution:

- Insert diameters of 15.5, 18.5, and 24.5 mm.

- Slit width of 3 mm; depth up to 0.5 mm.

- Stable, chatter-free cutting for smooth surfaces and minimal burrs.

The MULTI-MASTER chamfering heads are available with 45°- and 60°-point angles, and up to 6 flutes ideal for fast, accurate chamfering with excellent edge quality. In high-precision reaming, the BAYO-T-REAM system provides the following features: - Diameters range from 11.5 to 32 mm.

- Repeatability and run out within 3μm.

- Modular heads for blind and through holes, with internal coolant for improved chip control and surface finish. These solutions ensure that even the smallest features are machined to the highest standard delivering consistency, accuracy, and production efficiency at the final stage of machining.

Special Drilling Solutions for Complex Needs Trepanning, core drilling, and modular heads help solve some of the most difficult challenges in heat exchanger manufacturing.

TREPAN-DRILL

- Designed for core drilling applications that retain the removed material as a reusable core minimizing waste and increasing material use efficiency.

- Utilizes double-ended GRIP inserts made from high-performance SUMOTEC grades.

- Enables drilling up to 2×D depth with reduced cutting forces.

CHAM-IQ-DRILL (MD-DFN Modular Heads):

- Solid carbide heads with concave cutting edges sustain aggressive feed rates.

- Achieves IT8-IT9 tolerance levels, eliminating the need for secondary finishing.

- Quick indexing mechanism ensures long tool life and easy maintenance.

ISCAR-DR-DH (MD-DR-DH Modular Heads):

- Equipped with robust SOMX inserts featuring four effective cutting edges.

- Optimized for semi-finishing and rough operations under demanding conditions.

COMBI-CHAM Modular Drills:

- Available in standard diameters of 33.2, 36.2, and 39.2 mm.

- Guide pads ensure excellent drilling stability and straightness.

- Capable of drilling up to 8×D deep without the need for a pilot hole.

These advanced drilling systems are engineered for precision, stability, and productivity solving complex machining challenges while optimizing cost and material use.

From rough to finishing applications, ISCAR’s comprehensive tooling portfolio enables precise, reliable, and efficient manufacturing of heat exchanger components. By leveraging decades of experience and continuous innovation, ISCAR provides tailored solutions that not only meet industry standards—but often exceed them. Heat exchanger machining demands an integrated approach. ISCAR engineers every tool with performance and versatility in mind—because in this industry, there’s no room for compromises.