Machining Advanced Materials with ISCAR’s CBN and PCD Inserts

In the realm of modern manufacturing, precision and efficiency are paramount. ISCAR, a leader in the cutting tools industry, consistently pushes the boundaries of innovation, particularly with its Polycrystalline Diamond (PCD) and Cubic Boron Nitride (CBN) tools. These advanced materials are transforming how industries approach machining, offering significant advantages in cutting performance and tool longevity.

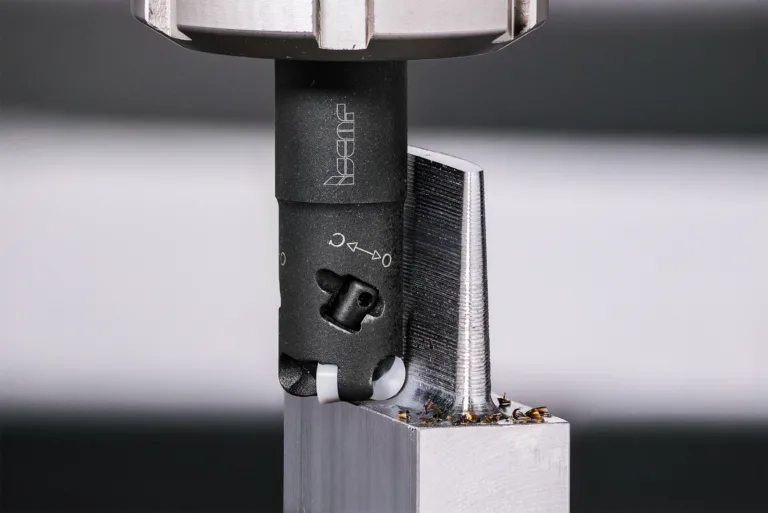

Polycrystalline Diamond (PCD) tools are renowned for their unparalleled hardness and wear resistance, making them ideal for machining non-ferrous metals, composites, and abrasive materials. ISCAR’s PCD tools are engineered to deliver high precision and superior surface finishes, which are crucial in industries such as aerospace, automotive, and electronics.

The benefits of ISCAR’s PCD tools are:

- Extended Tool Life: PCD’s exceptional hardness means that tools maintain their cutting edge for longer periods, reducing the frequency of tool changes and downtime.

- Enhanced Surface Finish: The fine-grain structure of PCD allows for superior surface finishes, essential for high-performance components where precision is critical.

- Increased Cutting Speeds: With PCD tools, manufacturers can operate at higher cutting speeds, leading to improved productivity and reduced cycle times.

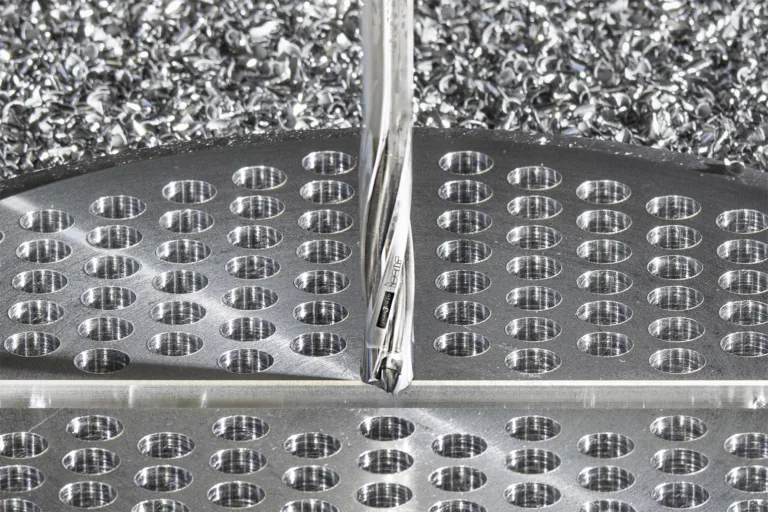

ISCAR’s innovations in PCD tooling include specialized geometries that enhance chip control and heat dissipation, further optimizing performance in demanding applications.

ISCAR’s Cubic Boron Nitride (CBN) tools are another cornerstone of ISCAR’s cutting-edge solutions, specifically designed for machining hardened steels, cast iron, and superalloys. CBN ranks second only to diamonds in hardness, making it an ideal material for tools that must maintain integrity under extreme conditions.

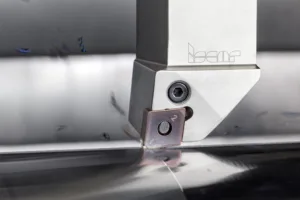

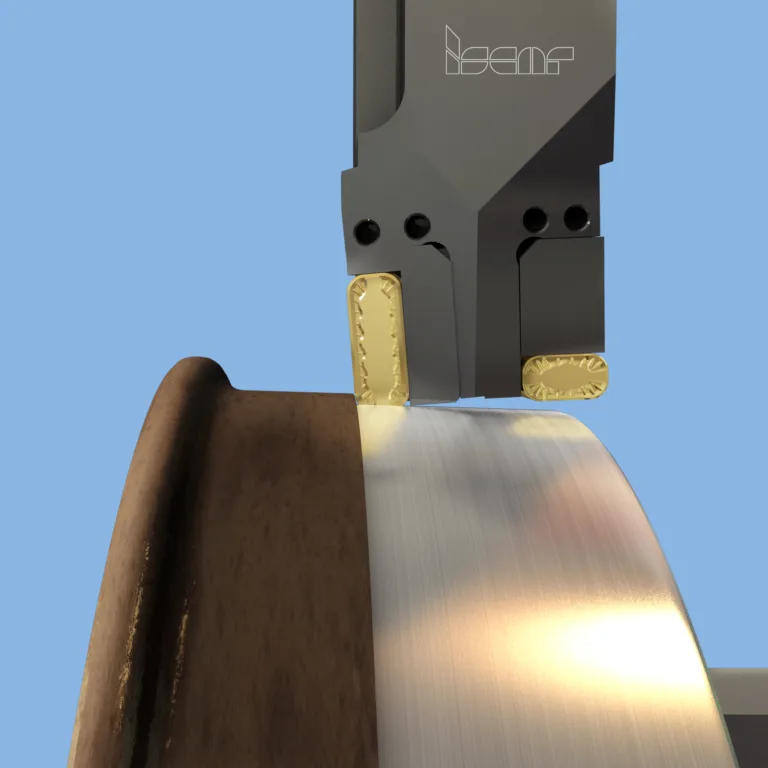

An important advantage of using CBN inserts is the ability to replace the slow and expensive grinding operations of hardened parts. Turning with CBN inserts significantly reduces the cost per part compared to grinding. ISCAR realizes that customers are changing their finishing processes from grinding to turning with CBN inserts, particularly in the automotive industry. In grinding operations, it is apparent that size tolerance specifications are beyond the capabilities of turning, while surface finish requirements are too tight for hard turning. In hard turning, the size tolerance specifications are beyond the capabilities of turning, showing a complex geometry that makes single point turning more practical with relatively high metal removal rates, dry machining, faster machine setup, and faster cycle times, enabling inner and outer diameter machining on one machine.

Compared to PCD, CBN is chemically passive when used in ferrous materials.

CBN is not found in nature. It is a synthetic material produced because of the high temperature and pressure process. The finished product consists of one carbide layer and one CBN layer. The combination of the two materials is called cubic-boron-nitride (CBN) wafer. CBN was developed to compete with the finish-grinding process of hardened ferrous materials (45-68 HRC) for economical cutting of up to 80-250 m/min. CBN is also used in cast iron machining applications, allowing for extremely high cutting speeds more than 1000 m/min. Cutting tools made of CBN sintered materials are created by mixing CBN (cubic boron nitride) with ceramics that are hard as diamonds. Together, these materials are sintered at extremely high pressure and temperatures. Sintered CBN provides improved cutting performance, particularly for high-speed machining materials like hardened steel, cast iron, and sintered alloys, due to its low affinity and high hardness qualities.

The key advantages of CBN tools are:

- Superior Hardness and Strength: CBN tools withstand high temperatures and maintain sharpness even when cutting hard materials, which is essential for industries like automotive and aerospace where hard turning is common.

- Improved Productivity: The durability of CBN tools allows for higher cutting speeds and feeds, translating to faster machining processes and increased throughput.

- Reduced Tool Wear: With exceptional resistance to thermal and chemical wear, CBN tools last longer than conventional carbide tools, leading to cost savings in the long run.

ISCAR’s commitment to innovation is evident in its development of multi-tipped CBN inserts with enhanced edge preparation, ensuring optimal performance in the toughest machining environments.

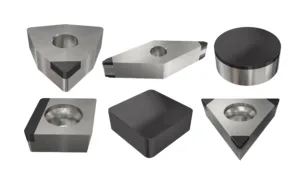

ISCAR’s insert types are designated as:

- MT Type – Mini-Tipped Turning Inserts, Multi-Cornered / One-Use Inserts: These one-use type inserts are designed to enhance machining efficiency by fully utilizing each cutting edge. Featuring a smaller and more economical CBN (Cubic Boron Nitride) tip, they contribute to significant cost reduction by offering more cutting edges per insert. The multi-cornered design includes a single piece of ISCAR-CBN mounted on every usable corner. Single-sided inserts utilize the top corners, while double-sided inserts make use of both the top and bottom corners. Available in various shapes, square and diamond-shaped inserts, known as “Quadro,” offer 4 corners, whereas triangular inserts, referred to as “triple,” provide 3 corners.

- MM, MF, MR Chipbreakers Type CBN Inserts: ISCAR offers a range of MT chipbreaker geometries designed to deliver optimal solutions for each specific application, ensuring perfect chip control in hard machining. These chipbreakers effectively prevent long chips and potential workpiece damage, while ensuring a stable and reliable production process. The MF-type inserts are tailored for fine to medium cutting, MM-type inserts are ideal for medium machining, and MR-type inserts are designed for roughing operations.

- L Full Edge Tipped Inserts: Designed for maximized productivity, this full edge tipped CBN inserts come in various shapes to suit different machining needs. Triangular-shaped inserts feature a full edge tipped with CBN, while square-shaped inserts offer either right-hand or left-hand full edge tipped CBN options. These inserts provide increased stability, enhancing overall machining performance

- HS Type Half Solid CBN Inserts: These inserts feature a top layer of CBN with a carbide base, offering multiple cutting edges. The high hardness achieved through a special binder result in excellent wear resistance, impact resistance, thermal stability, and chemical stability, making them ideal for metal processing. They provide exceptional cost performance, saving 30%-50% compared to carbide inserts, and deliver excellent surface quality, enabling turning instead of grinding. The solid material ensures a high degree of mechanical strength, making them a superior cutting tool material for extreme conditions. These inserts lower machining costs, require fewer tool changes, and offer high machining efficiency, being 5-10 times more efficient compared to carbide and ceramic inserts.

- Solid CBN inserts are versatile and can be used across diverse industries such as automotive parts, roll industry, gear industry, bearing industry, wind power generation, and air conditioning compressors. They are particularly effective for workpieces made of cast iron and hardened steel, including automotive engine components, brake discs, brake drums, pulleys, cylinder blocks, cylinder liners, pumps, and cast-iron rolls. For hardened steel, they are suitable for industrial gears, wind power bearings, bearings, drive shafts, crushing hammer cylinders, and slurry pumps

S Type Full Solid CBN Inserts are designed for aggressive machining conditions, offering numerous advantages such as excellent wear resistance, impact resistance, thermal stability, and corrosion resistance. They provide strong thermal stability and are ideal for high-speed, efficient machining, particularly in roughing applications. With excellent cost performance, these inserts save 30%-50% compared to carbide inserts, while delivering superior surface quality, enabling turning instead of grinding. The solid material ensures a high degree of mechanical strength, making them superior cutting tool material under extremely hard conditions. These inserts reduce machining costs and require fewer tool changes, achieving high machining efficiency that is 5-10 times greater than that of carbide and ceramic inserts.

S Type Full Solid CBN Inserts are suitable for machining cast iron components in the automotive industry, including engine parts, brake discs, brake drums, pulleys, cylinder blocks, cylinder liners, pumps, and cast-iron rolls. They are also ideal for roll applications such as metallurgical rollers and mill rolls, as well as bearings, slurry pumps, wind power generation components, air conditioning compressors, heavy mining machinery, and other industrial hardened steel applications. Additionally, they are effective for machining industrial gears, wind power bearings, drive shafts, crushing hammer cylinders, and slurry pumps.

In conclusion, ISCAR’s PCD and CBN cutting tools are at the forefront of machining technology, offering solutions that meet the highest standards of precision, efficiency, and durability. As industries continue to demand more from their machining processes, ISCAR’s dedication to research and development ensures that their tools remain at the cutting edge, driving productivity and performance across the globe.