Innovative Metalworking Solutions for Electric Vehicles by ISCAR

As the automotive industry accelerates toward an electric future, the demand for precision, efficiency, and innovation in manufacturing has never been higher. ISCAR, a world leader in cutting tool solutions, is at the forefront of this transformation, offering advanced metalworking solutions tailored specifically to produce electric vehicles (EVs). Public awareness of global warming, together with a pressing concern to create and maintain a clean environment, has led to a series of legislations worldwide that is forcing automakers to decrease CO2 emissions. Many countries have already declared a ban on sales of internal combustion vehicles soon. Apart from improving fuel consumption, downsizing engines and making lighter vehicles, automakers must turn to new technologies to cope with these emission limitations. A rapid increase in battery electric vehicle development, manufacture and implementation, shows that electric vehicles are not only the future but are, in fact, the present. The automotive industry is on the brink of colossal changes and soon our perception of cars and transportation may alter completely.

A New Era in Manufacturing

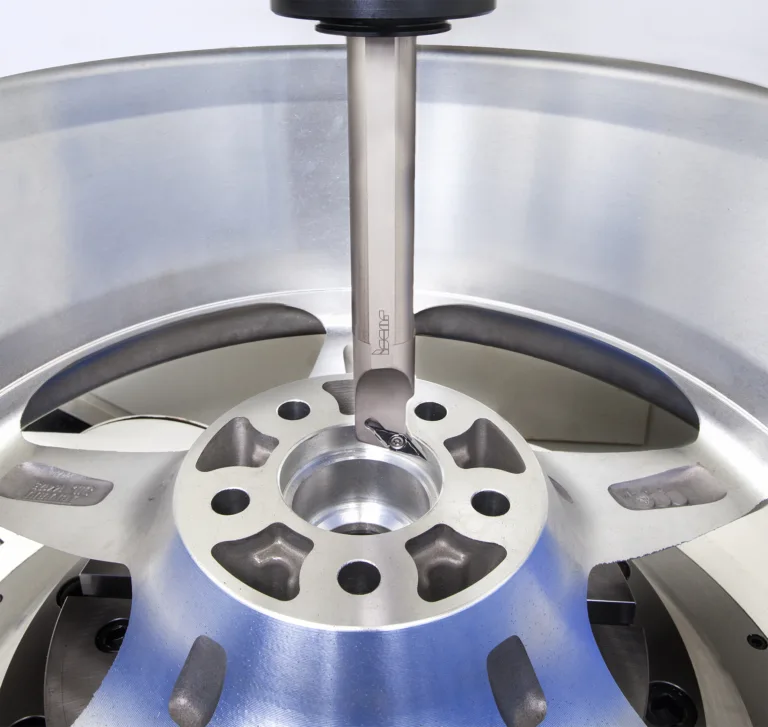

Electric vehicles represent a significant shift in automotive technology, prioritizing energy efficiency, sustainability, and high performance. This shift brings unique challenges and opportunities in the manufacturing process. Components such as battery housings, electric motors, and lightweight chassis materials require advanced machining techniques to meet stringent quality and performance standards. ISCAR has a rich history of providing cutting-edge solutions to various industries, and their commitment to innovation is evident in their approach to EV manufacturing. By leveraging advanced materials, precision engineering, and state-of-the-art technology, ISCAR delivers tools that enhance productivity, reduce costs, and ensure the highest quality standards. The R&D team of ISCAR studies the best productive options for any application, from boring to contouring and finishing outside diameter (OD) (Fig. 1). With a variety of polycrystalline diamond (PCD)-tipped tools or inserts, the milling line ensures the best cycle time, surface finish quality and performance. Special PCD tools guarantee the achievement of the typical qualitative and quantitative parameters of the automotive sector. ISCAR is committed to its customers by providing the most technologically advanced solutions in quality and stable machining operations.

Fresamento

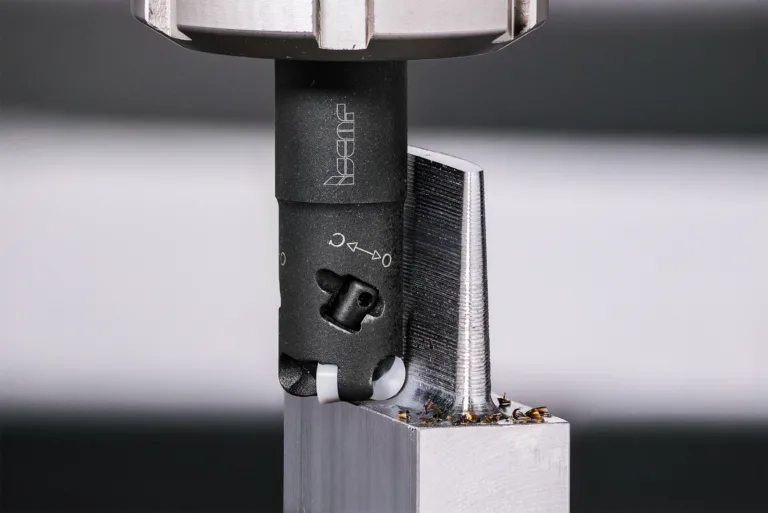

MULTI-MASTER Heads:

These interchangeable heads offer versatility and precision, ideal for milling complex geometries in lightweight materials such as aluminum and composites used in EV chassis and battery enclosures. MULTI-MASTER interchangeable solid carbide heads are dedicated for machining aluminum and may be used for both roughing and finishing. The design features 4 polished flutes for optimal chip evacuation and excellent chatter damping abilities, easy tool change capabilities and no setup time. HELIALU And HELI2000 Indexable Milling Families: Designed for high-efficiency machining, these indexable milling tools provide superior surface finish and extended tool life, essential to produce critical EV components.

Torneamento

ISCAR’s Turning Tools with Indexable ISO-Type Inserts: Featuring a wide range of inserts and toolholders, this line ensures optimal performance in turning operations, crucial for producing high-precision electric motor components and other cylindrical parts. The rotor consists of many stacked plates of electric steel. Lamination sheets are used instead of a solid body to reduce current loss. The surface must be completely clean of chips, oil, water, dust or dirt, and coolant fluid cannot be used, only air. This is a challenge as a lot of heat is generated on the cutting area and the fragmented chips stick to the surface. Surface finish requirements for this interrupted turning operation remain strict. ISCAR has overcome these challenges by developing a combined tool with coolant holes both on top and bottom of the cutting edge to cool and blow away the chips. The two round inserts are positioned for semi-finish and finish operations, generating an Ra1.9 surface roughness (Fig. 2).

ALU-P-TURN Solutions:

With its robust design and enhanced chip control, ALU-P-TURN indexable turning tool family is perfect for high-volume production environments, delivering consistent quality and efficiency. CUT-GRIP and SELF-GRIP: ISCAR’s parting, grooving, and threading tools are designed for versatility and reliability, enabling the production of complex thread profiles and grooves required in EV assembly.

TANG-GRIP:

This innovative system offers excellent clamping stability and reduced setup times, enhancing productivity in grooving operations. Multi-Function Tools are the trademarks of ISCAR’s solutions for increasing productivity. These tools make it possible to combine different operations to reduce the cycle time.

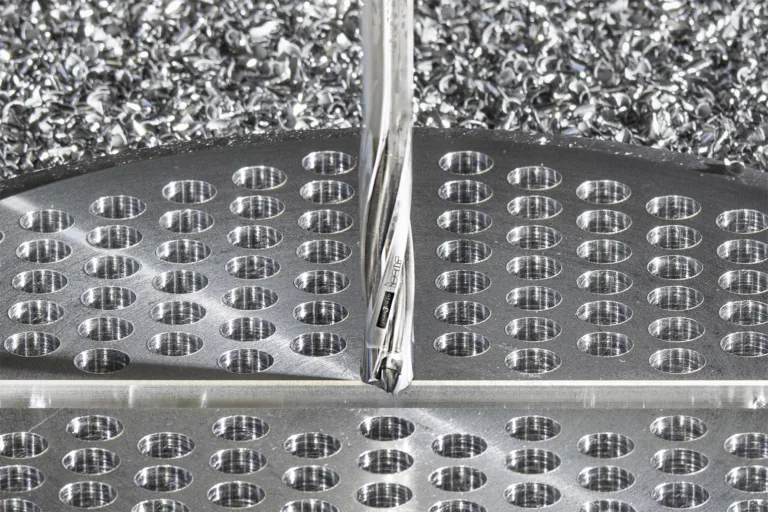

HOLEMAKING

SUMOCHAM Drills:

For holemaking operations ISCAR offers several options for drilling aluminum and non-ferrous materials that are based on assembled SUMOCHAM drills with exchangeable heads made from solid carbide, including ICN heads designed with a sharp cutting edge and polished rake face, and ICG heads with a chip splitter for better chip removal when working with a long overhang. The SUMOCHAM modular drills provide quick and easy head changes, reducing downtime and increasing productivity. Their high penetration rates and excellent chip evacuation are particularly beneficial for drilling operations in EV manufacturing.

BAYO T-REAM Reamers:

In machining aluminum automotive components, special customized interchangeable cutting heads with PCD tips for high-speed BAYO T-REAM reamers can be made on request. RM-BN-RC-RING adjustment rings for BAYO T-REAM holders solve tool runout caused by the machine spindle, holder weight (in horizontal applications) or long overhang. Each size has its own diameter range and holder. For example: The same RM-BN7 holder can hold any head between Ø16.001–20.000 mm.

ADVANCED COATINGS

For machining aluminum and non-ferrous materials, a special diamond-like-carbon (DLC) coating for higher cutting conditions and longer tool life can be applied.

ENGINEERING ANALYSIS

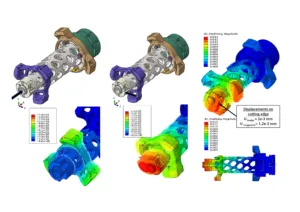

In cutting tool development, Finite Element Method (FEM) enables the consideration of many parameters, such as cutting forces, displacement field during machining, natural frequency, and maximum deformation. ISCAR’s tool design engineers utilize FEM analysis and chip flow modelling to resolve the obstacles associated with this challenging application (Fig. 3).

SUSTAINABLE MANUFACTURING PRACTICES

In addition to providing advanced tooling solutions, ISCAR is committed to promoting sustainable manufacturing practices. The tools are designed to minimize material waste, reduce energy consumption, and improve overall operational efficiency. By adopting ISCAR’s solutions, manufacturers can contribute to a more sustainable and eco-friendly production process.

*** ISCAR’s approach to supporting the EV industry goes beyond providing high-quality tools. ISCAR’s engineers work closely with manufacturers to understand their specific needs, offering tailored solutions (Fig. 4) and technical support. This partnership ensures that manufacturers can achieve their goals of efficiency, quality, and innovation in EV production. As the electric vehicle market continues to grow, ISCAR remains a trusted partner for manufacturers seeking advanced metalworking solutions. With their comprehensive range of high-performance tools, commitment to innovation, and focus on sustainability, ISCAR is driving the future of EV manufacturing, helping to build a cleaner, more efficient automotive industry. For more information on ISCAR’s metalworking solutions for electric vehicles, visit the website or contact the company’s expert team to discuss your specific requirements.