Solid Ally

Since the late 1990s, solid carbide endmills (SCEM) have become one of the focal points in the metalworking industry. Several factors contribute to this prominence. Firstly, compared to indexable milling cutters, solid carbide endmills offer distinct advantages: greater precision, suitability for small-diameter mill designs, and better options for engineering balanced tool structures. Additionally, SCEM outperforms their counterparts made from high-speed steel (HSS), as the harder carbide material provides higher wear resistance and maintains a sharp cutting edge longer, resulting in extended tool life.

Understandably, the known advantages alone were not sufficient to explain the rapid growth of the share of solid carbide endmills in milling products that began in the 1990s. There were additional elements that contributed to the increased use of SCEM in the industry. The advancements in CNC machining technology and the growing interest in high-speed milling (HSM) methods highlighted the need for tools that are suitable for high cutting speeds, and solid carbide endmills perfectly meet these demands. The quantum leap in tool grinding CNC machines and CAD/CAM systems played a crucial role in the major progress and growing popularity of SCEM during that period. This considerable leap forward was a key factor, a real game-changer, which gave rise to a significant breakthrough:

- The enhanced capabilities of tool grinding CNC machines enabled substantially increased accuracy and the production of solid tools with high-precision geometries.

- CAD/CAM systems enabled the design and manufacturing of endmills with complex geometries that were previously difficult to achieve. Tool grinding simulator software allowed for a virtual analysis of the grinding process, considerably contributing to the precise production of SCEM.

• The integration of CAD/CAM systems with tool grinding CNC machines provided a powerful tool for endmill customization in accordance with the specific requirements of the customer. - The efficient tool grinding CNC technology diminished production times and reduced fabrication costs, making high-quality solid carbide endmills much more attractive and commercially viable for both the tool manufacturer and the customer.

- Advanced tool grinding CNC machines and CAD/CAM systems also contributed to improved quality control, ensuring consistent tool parameters.

In addition, advancements in materials science and powder metallurgy led to the development of advanced carbide substrates with smaller grain sizes, providing higher hardness and wear resistance. Combined with new progressive coatings, such as TiAlN, these substrates formed carbide grades featuring prolonged tool life, making them almost ideal for SCEM intended for machining at high cutting speeds and milling hard materials. Hence, solid carbide endmills have become essential tools for performing effective machining operations, and now SCEM hold a significant portion of the milling cutter market. According to various estimates, solid carbide endmills account for approximately 50% of this market. Moreover, the SCEM share does tend to grow. The successive expansion of CNC machining, the rise of HSM processes, and the decreasing machining stock due to precise workpiece fabrication using accurate die-casting, forging, and injection molding, on the one hand, and the further advances in carbide materials and coating technologies, on the other hand, determine the trends in SCEM development and present appropriate challenges to the tool manufacturer. These trends include:

- In carbide grades, the increased usage of submicron carbides and wear-resistant coatings like TiAlN, AlTiN, diamond coating, and others is prevalent.

- In tool shapes and cutting geometries, more complicated and “intelligent” designs are becoming common. Unequal angular pitch, variable helix, and chip-splitting cutting edges are frequently utilized.

- In high-efficiency machining, there is a distinct emphasis on SCEM optimized for high-speed milling (HSM) and high-feed milling (HFM).

- In tool accuracy, the metalworking industry demands increasingly precise and balanced tools to maintain strict machining tolerances and enable stable operation at high rotational velocities, especially in finish cuts.

- Customized solutions – to meet specific application requirements, tool manufacturers are developing specially tailored products comprising unique carbide grades and cutting geometries.

- Multifunctionality – there is a growing demand for multifunctional SCEM that combine various cutting functions such as milling, drilling, chamfering, and more.

- Digitizing – the impact of Industry 4.0 on metalworking highlights the importance of digital tool companions, which include available digital twins, 3D models and 2D drawings, easy access to specified cutting data, engineering calculations, tool life estimation etc.

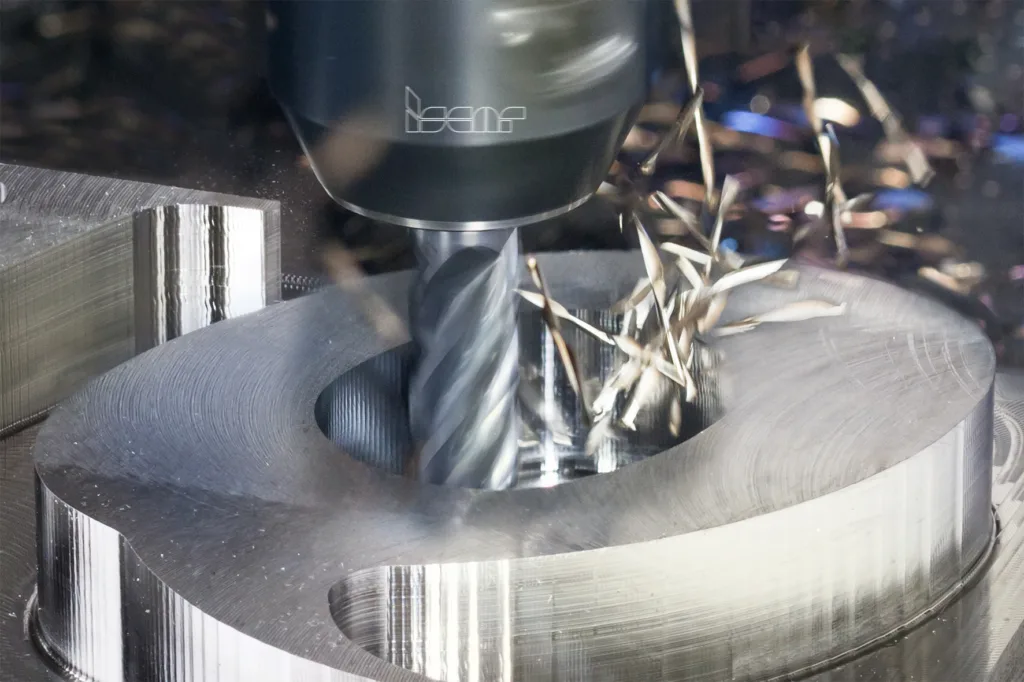

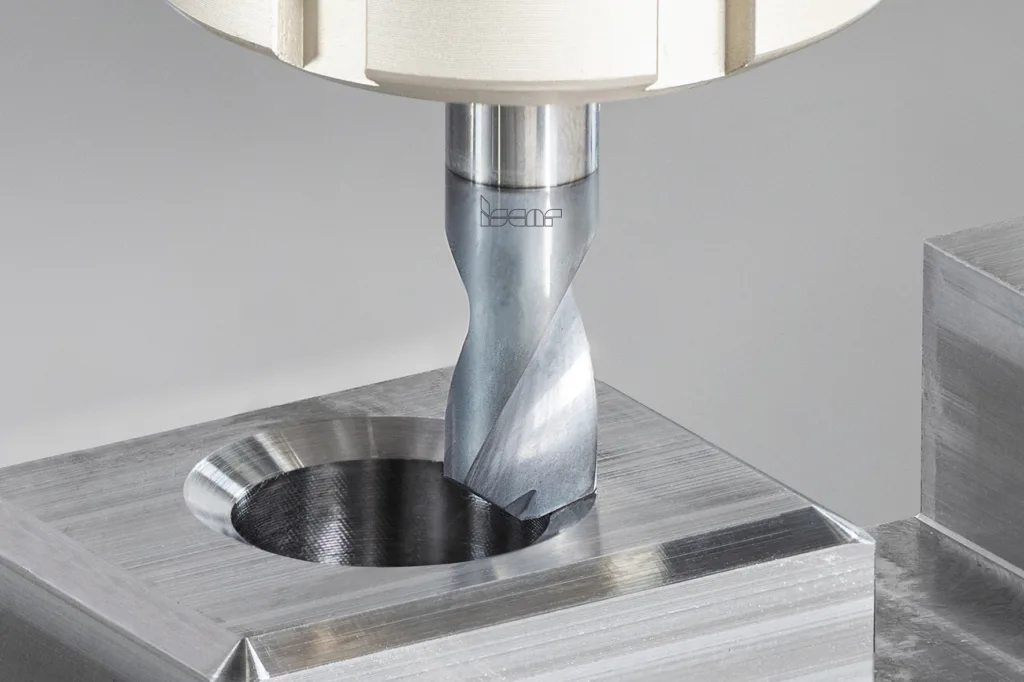

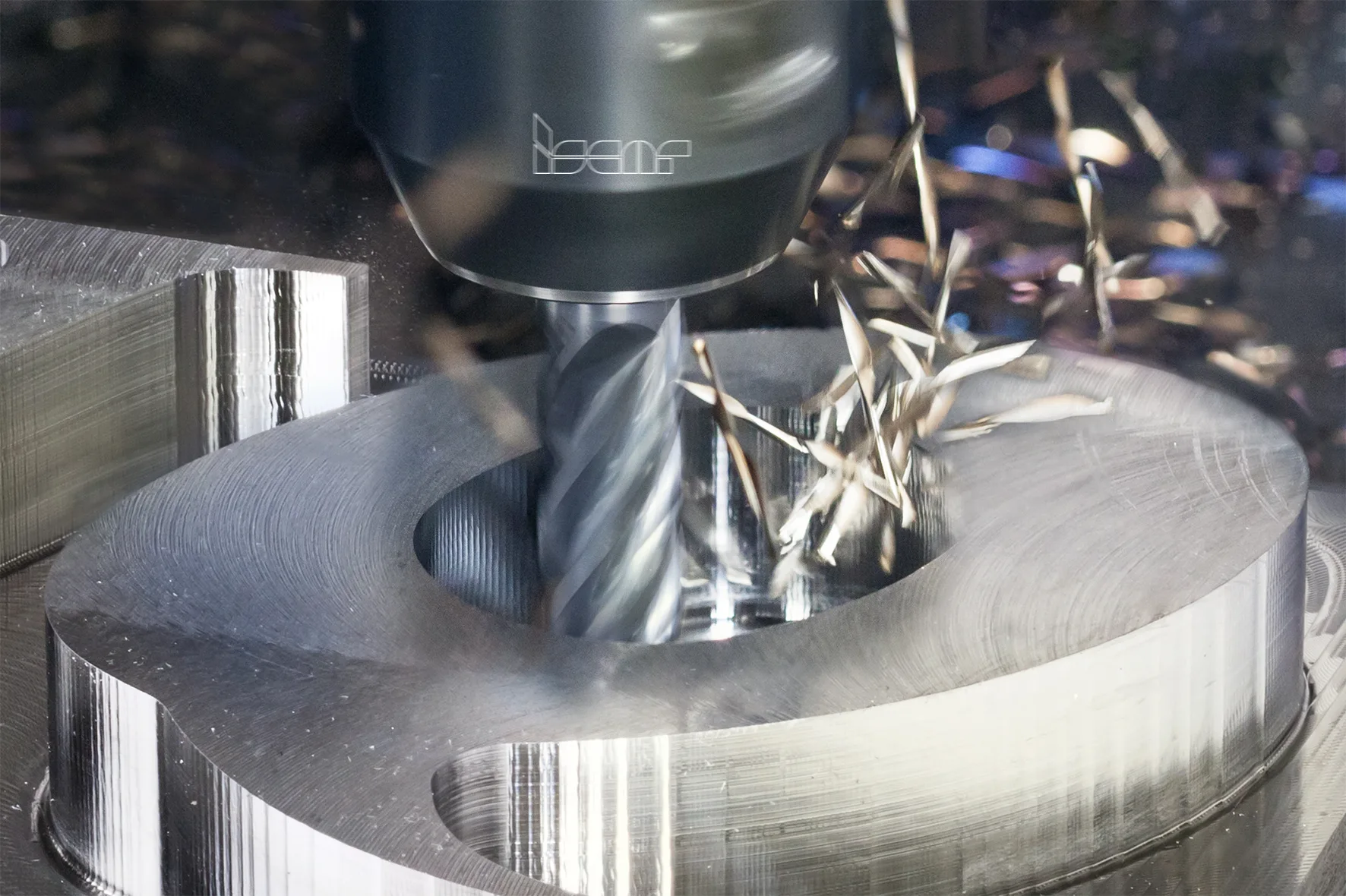

When examining two solid carbide endmills of similar dimensions, it is difficult to identify visible differences. Even using a magnifying glass or microscope may not always help in this search. However, these cutters can exhibit significantly different performance indicators, making the differences quite evident. Let’s consider the latest developments from ISCAR and understand how ISCAR addresses these challenges. Even a quick glance at ISCAR’s solid carbide endmill product range reveals an interesting trend in SCEM products from an application perspective. In the past, the emphasis was on an all-purpose design concept that allowed endmills to be used across a broad spectrum of engineering materials. However, many of the new developments are now focused on providing the most effective for milling specific material groups. For instance, the Ti-TURBO endmill family has been purposefully designed for machining titanium alloys. This family includes SCEM with precision-engineered cutting geometries, featuring a four-flute design for various operations, such as milling slots up to two-tool-diameter depth in solid material. Additionally, it offers seven- and eight-flute designs for high-speed milling using the trochoidal technique. The Ti-TURBO tool concept is based on different flute helix angles and variable pitch to enhance dynamic rigidity and improve chatter dampening when milling titanium alloys, including difficult-to-cut grades like “triple 5” (Ti-5-5-5-3), at high metal removal rates (MRR). The popular family has significantly expanded with new products during ISCAR’s latest LOGIQUICK campaign.

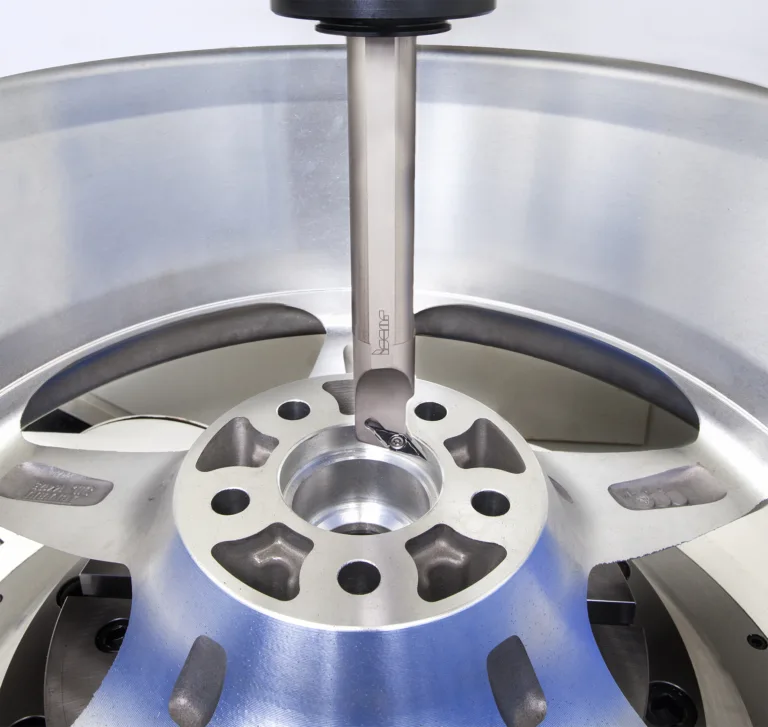

Chatter-free designs based on the concepts of variable helix, unequal tooth pitch, and their combination characterize various ISCAR solid carbide endmills. These designs ensure high machining stability and allow for producing tools with enlarged cutting lengths. In recent years, the portfolio of chatter-free SCEM has been expanded with new products offering a great choice of corner radii, increased cutting lengths, a central coolant hole for easy chip evacuation, and chip-splitting geometries to divide wide chips into small segments. Another example is the EC-A2-T – a series of miniature, highly accurate two-flute endmills in the diameter range of 0.3 to 4mm, designed for high-speed machining of primarily pre-hardened and hardened steel (Fig. 3). These tools have recently been upgraded with IC602 – a high-hardness submicron carbide grade with an AlTiSiN PVD coating, enhancing performance when milling steel with hardness up to HRC 65 (ISO H group of applications). For cutting aluminum and non-ferrous materials (ISO N group of applications), ISCAR offers newly introduced three-flute SCEM made from IC1508 – a submicron carbide grade with a diamond-like carbon (DLC) coating. The multifunctional ECD-S2 solid carbide tools combine spot drilling and chamfer milling capabilities. In addition to the existing tools with a cutting tool angle of 45°, ISCAR has introduced tools with cutting edge angles of 30° and 60° to meet customer demands. These versatile tools find their use in almost every machine shop.

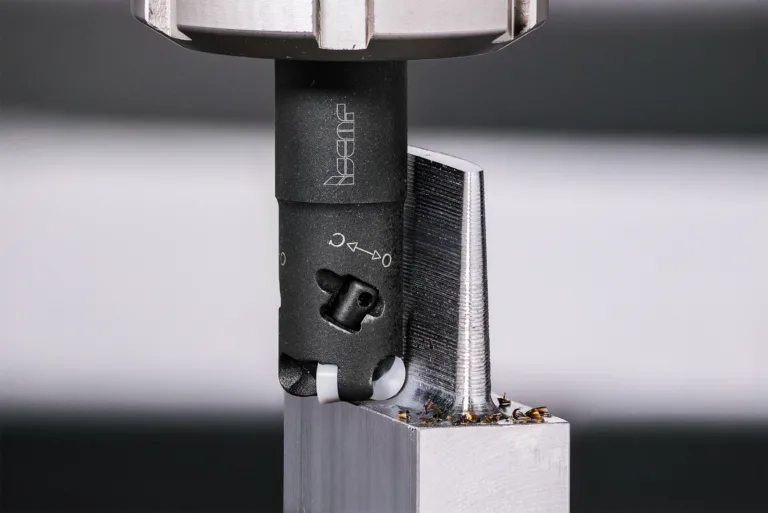

New products also feature the SOLID-FEED-MILL family of multi-flute SCEM for high-feed milling. Their design minimizes the radial component of cutting force to decrease the bending load and enable machining at high feed rates, even when machining with long overhang.

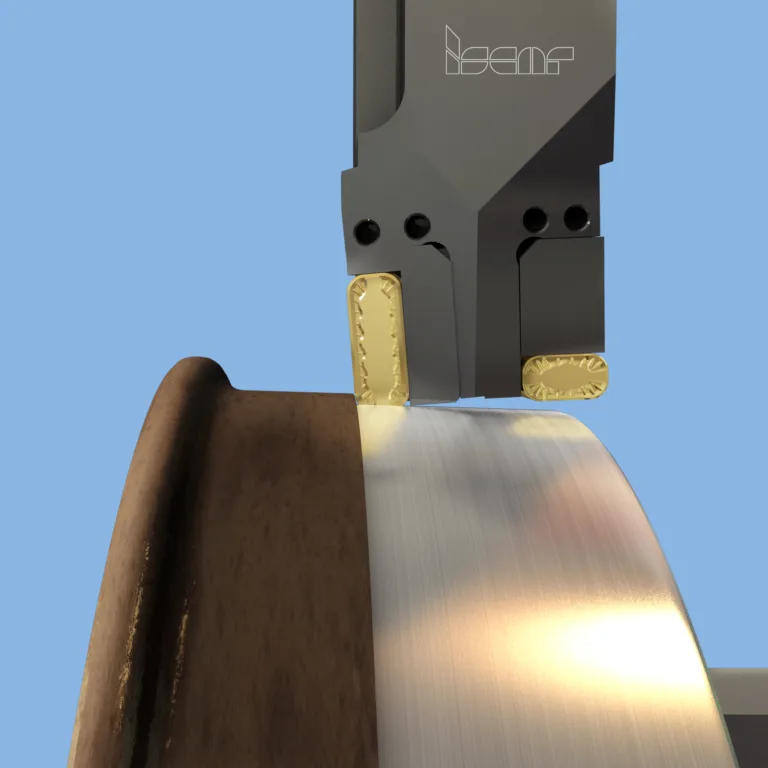

The recently unveiled NEOBARREL oval-shaped solid carbide endmills are intended for 5-axis machining of complex 3D surfaces. These tools ensure precise and productive cutting of complicated profiles. In recent years, ISCAR has substantially expanded its digital tool component, which is based on the ISO 13399 standard. This component includes various options, such as 3D and 2D tool representations for computer modeling, CNC programming, and process planning. It also generates a STEP (.p21) file for data exchange and offers enhanced functions for virtual assembly and tool search. Additionally, it provides the capability to select the optimal tool solution for specific applications, among other features. As expected, all these options also apply to solid carbide endmills.

In the ISCAR electronic catalog (e-catalog), the tool search functions, including the SCEM selection, have been considerably extended. The new customer-oriented search options allow for finding a more suitable solid carbide endmill according to the type of machined material, adaptation, dimensions, cutting material grade, characteristic features such as the number of flutes, and other key parameters that make endmill selection easier and more effective.

The examples shown of new ISCAR products in the field of solid carbide endmills are good illustrations of the company’s response to the latest development trends in terms of performance, application range, accuracy, and reliability. By staying up to date with these trends, ISCAR’s solid team continues to develop innovative solutions that meet the evolving needs of the metalworking industry.