Cutting with Polygon Shaped Inserts for Efficient Turning “With every new tool comes a fresh perspective on creativity.”

The concept of assembled cutting tools with replaceable carbide inserts, mechanically clamped into a tool body, was first practically realized in the late 1950s. Much has changed since then, especially regarding the shape of these inserts. Advances in powder metallurgy and pressing technology have enabled a transition from relatively simple insert shapes to much more complex forms. In most modern inserts, flat faces with clearly defined edges have been replaced by smooth 3D surfaces. These developments are the result of ongoing design efforts aimed at finding the best combination to achieve the following targets:

– Optimum cutting geometry for effective chip formation.

– Intelligent outer shapes to maximize the range of machining applications.

– Rational, sustainable use of cutting materials for cost-efficiency.

The world of replaceable cutting inserts designed for turning, milling, drilling, or threading tools features remarkable diversity in insert geometry: square, round, octagonal, rhombic, trigon, curvilinear, and others. Inserts can be one-sided, with cutting edges on the top face only, or double-sided (reversible), with cutting edges formed on both the top and bottom faces. It is interesting to note that these changes have influenced terminology. While the first mechanically clamped inserts were referred to as “throwaway,” highlighting the fact that they could be discarded after use, today they are more commonly described as “indexable,” which emphasizes their ability to provide multiple replaceable cutting edges. It may appear that the variety of insert shapes and surfaces is not limitless and that the rich world of inserts, diverse in profiles, is near saturation. However, tool manufacturers think otherwise and continually introduce new insert geometries into their designs to achieve the ideal compromise for the objectives mentioned above. In many cases, using established, “canonical”, insert configurations also opens new prospects for meeting design requirements. An example of this can be found in the indexable turning inserts recently developed by ISCAR, as part of the latest LOGIQUICK campaign.

Cutting Pentagon for Cost-Efficiency and Versatility

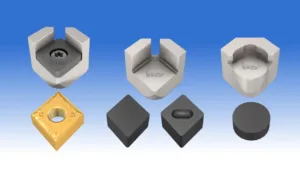

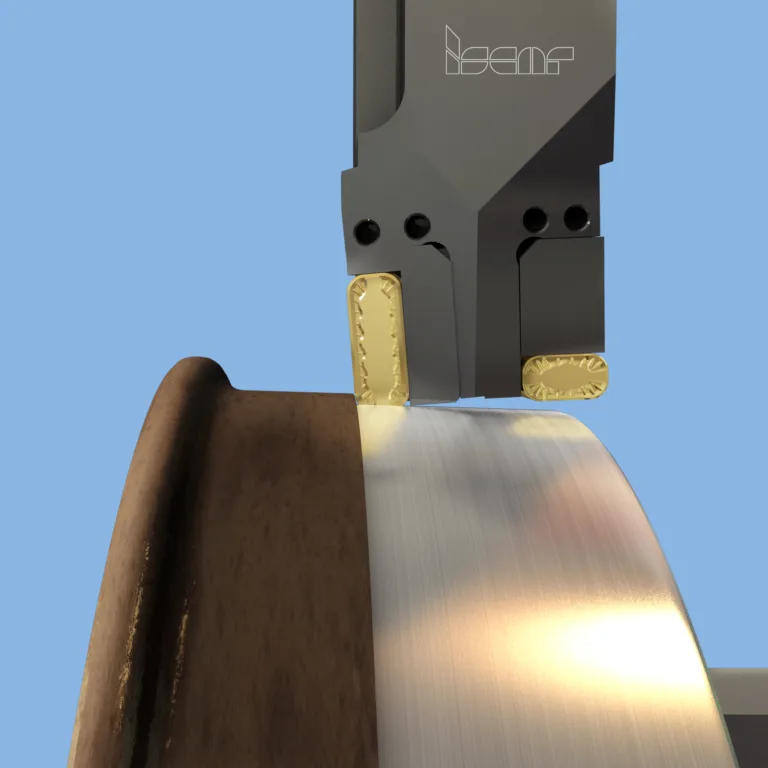

The POMG is a double-sided pentagonal carbide insert, which serves as a key component in the latest additions to the DOVE-IQ-TURN family of turning tools (Fig. 1). Its pentagonal shape and reversible design provide ten indexable cutting edges – five on the top and five on the bottom – for optimal cost-effectiveness. The specially shaped side surfaces allow the insert to be securely clamped into a dovetail-profile pocket, ensuring extremely rigid fixation to withstand significant mechanical loads during machining. This insert is designed for use with two types of tools that differ in their entering angle: 55° for rough to semi-finish applications with cutting depths of up to 5 mm, and 14.5° for high feed turning with shallow depths of cut (up to 1.5 mm). The insert corner is formed by a radius flanked by two wiper flats on either side. This design is intended to improve surface finish, even when roughing at high feed rates. To summarize, the regular-pentagon shape and innovative design features result in a highly economical and versatile insert with a durable structure, ensuring productive cutting and good surface quality. This opens promising opportunities for reducing machining costs, especially in rough turning operations.

Concave Hexagon Options

In turning operations, a concave equilateral hexagon shape for indexable inserts offers a significant advantage – the expanded effective range of the insert. This shape enables machining of hard-to-reach areas while also increasing the number of indexable cutting edges. Its symmetry is perfectly suited to the demands of multi-directional cutting. It is therefore not surprising that the concave equilateral hexagon has been selected as the shape for the latest Q6-MNMG inserts (Fig. 2), which are mounted in ISCAR’s QUICK-TURN tools for machining in multiple directions (such as front and back), profiling, facing, and more, especially in roughing applications that feature significant load. To ensure a fixed position and handle variable cutting forces when turning in multiple directions, the insert features three ridges on both its top and bottom surfaces. These ridges fit into corresponding grooves in the base of the insert pocket. Importantly, the ridges, located on the rake faces, do not hinder chip flow during cutting. This new solution, which utilizes concave-hexagonal indexable inserts, delivers impressive performance and allows various tasks to be accomplished with a single versatile turning tool.

The concave hexagon insert has found further applications in yet another product called the QUICK-T-LOCK tool family, which is also designed for multi-directional turning. Unlike the previously discussed solution based on the negative insert concept, the one-sided Q3-MCMT QUICK-T-LOCK insert (Fig. 3) features a positive structure, with inclined side faces and the bottom of the insert being smaller than the top. Compared to the negative profile of a double-sided insert, the Q3’s configuration provides a more positive cutting geometry, resulting in lighter and smoother cuts. Additionally, the inclined side faces of the Q3 inserts offer better capability for machining hard-to-reach areas. However, the one-sided insert concept yields only three cutting edges which is half as many as the Q6. In conclusion, the concave hexagon can be successfully applied to insert designs in tools intended for both heavy roughing and precise light cuts in multi-directional turning.

Cartridges Come to Help

How can inserts of different shapes be mounted in the same tool body? Solving this challenge gives new momentum to the intelligent use of the body, increases its versatility, and reduces the number of tool types that a customer needs to keep in stock. Sometimes, a well-designed insert pocket can accommodate different insert shapes. However, in most cases, the pocket configuration and the insert shape are closely interrelated, so basically the pocket is intended for mounting inserts of the same contour. An effective solution to this problem is to use exchangeable cartridges that can be mounted in the tool body. Each cartridge is designed with a pocket suitable for securing a specific insert shape. This approach offers an additional advantage: if an insert breaks, the tool body remains unaffected. Simply replacing the damaged cartridge allows continued use of the body.

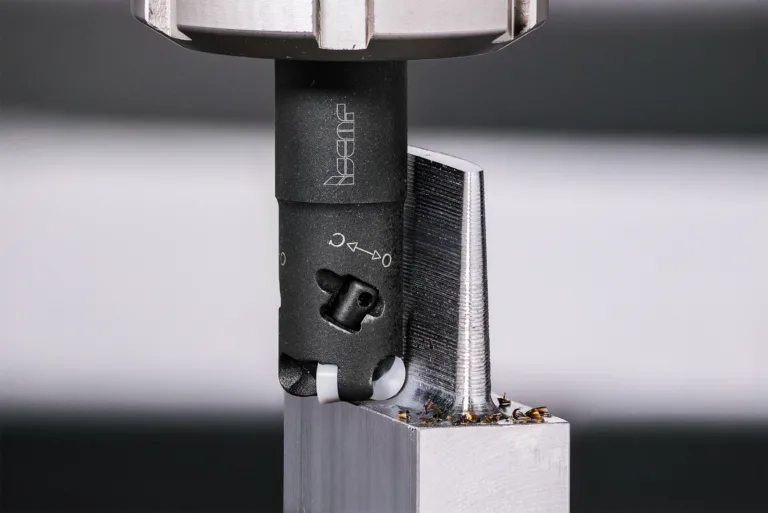

This concept is realized in ISCAR’s CER-M-TURN turning tools. The tool bodies (holders) with square or polygonal-taper shanks are designed to accommodate exchangeable cartridges for rhombic and round inserts made from cemented carbides, ceramics, cubic boron nitride (CBN) or tipped with polycrystalline diamond (PCD) (Fig. 4). If needed, a carbide seat can also be mounted in a cartridge. The holders have coolant outlets, directed to the cutting edge for high pressure cooling (HPC) with adjustable options to maximize cooling and lubricity. In addition, the design incorporates an enhanced clamping mechanism to prevent rotation or breakage of brittle ceramic and CBN inserts, ensuring optimum performance and extended tool life.

The shape of an indexable insert is determined by the need to meet specific design requirements. Although there are understandably only a limited number of possible shapes, the diverse world of inserts continues to expand, with even known profiles finding new applications.