Machining Aluminum Wheels with ISCAR for Advancing Productivity and Quality

In recent years, additive manufacturing (AM), commonly known as 3D printing, has emerged as a transformative force across various industries, including metalworking. This technology, characterized by its layer-by-layer material addition process, contrasts with traditional subtractive manufacturing methods and has introduced a new paradigm in the design and production of metalworking tools. ISCAR’s additive manufacturing is affecting the evolution of metalworking tools, highlighting the benefits, challenges, and future potential of this innovative approach to assure customers receive tools to increase productivity and metalworking efficiency.

The aluminum wheels industry is experiencing rapid and sustained growth, driven by the constant demand for new vehicles across global markets. Consumers increasingly prefer stylish, lightweight, and high-performance wheels, which has led manufacturers to expand production capacity and adopt more efficient manufacturing processes. This market expansion, however, comes with intense competition, as manufacturers must balance the demands for cost efficiency with the need to deliver superior quality. The price of an aluminum wheel is influenced not only by raw material costs but also by the machining technology and production methods employed in its manufacture.

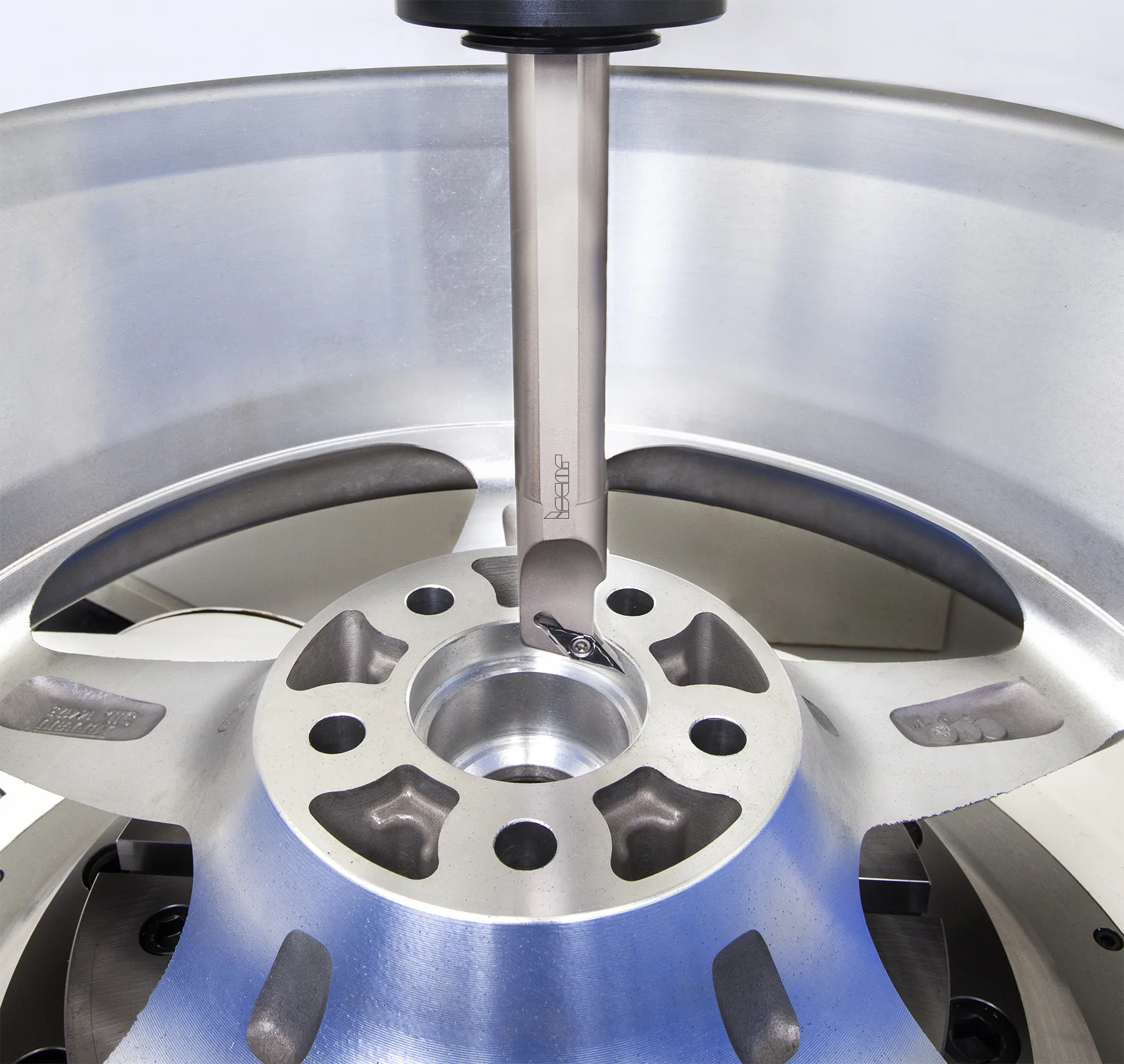

Aluminum wheel manufacturers operate in a fast-paced production environment where precision, surface quality, and cycle times significantly affect profitability. They must meet the automotive industry’s stringent dimensional and aesthetic standards while ensuring that production remains efficient and cost-effective. This requires tools and systems that can accommodate high cutting speeds, withstand heavy cutting forces, maintain consistent performance, and deliver a flawless finish that enhances the wheel’s appearance (Fig.1). These challenges are compounded by the trend toward mass customization, where different wheel designs, sizes, and finishes must be produced with minimal downtime and setup changes.

ISCAR addresses these industry needs by providing advanced, cost-effective machining solutions specifically developed for aluminum wheel production (Fig.2). The company’s tool systems are engineered to optimize productivity, extend tool life, and consistently produce superior surface quality in demanding machining operations. ISCAR’s solutions cover the full range of wheel manufacturing processes, including outer diameter and inner diameter machining, facing, undercutting, and the drilling of valves, lugs, and center holes. Among ISCAR’s leading technologies is the DTF Quick Change Toolholder system, designed for speed, stability, and accuracy in high-volume production (Fig.3). This system is particularly well-suited for automatic machining stations, where stable tool life is essential. Its user-friendly design allows the operator to clamp or release tool heads using a single screw, drastically reducing changeover time. The system’s dovetail face contact provides maximum rigidity and stability, ensuring precise machining under both axial and radial forces. DTF tools are compatible with ISCAR’s GRIP and ISO insert families and are suitable for use with emulsion and Minimum Quantity Lubrication (MQL) systems. This makes them a favored choice among aluminum wheel manufacturers seeking to improve efficiency without compromising performance.

Maintaining the correct temperature during aluminum machining is crucial for achieving the high surface quality required in wheel production. ISCAR’s DTF tooling integrates a targeted coolant supply that delivers coolant directly to the cutting edge, reducing heat buildup, improving chip evacuation, and prolonging tool life. This precision cooling approach supports both productivity and product quality.

In applications requiring the highest possible cutting performance, ISCAR recommends Polycrystalline Diamond (PCD) inserts. Designed for stability under high cutting conditions, PCD inserts are available in multiple geometries, including ISO 35° rhombic shapes and full-radius designs, with or without chipbreakers. These inserts can be used for roughing, semi-finishing, and finishing (Fig.4). Special bright-facing PCD inserts are also available to prevent surface porosity and burr formation after painting, ensuring that wheels meet the strict visual standards expected by both automakers and consumers.

For cost efficiency, ISCAR offers the VNGU ISO 35° rhombic insert, which features four cutting edges, a 7° positive flank, and a very positive rake angle. Its sharp, polished cutting edge is engineered for aluminum wheel machining, delivering improved chip control under high-pressure coolant, an extended tool life, and excellent finish—all while lowering per-part costs (Fig.5).

ISCAR also provides a complete range of drilling solutions tailored to the specific needs of aluminum wheel manufacturers. These drills are designed for the precision machining of center holes, lug holes, valve holes, and back chamfering. They are available in solid carbide, indexable insert, and PCD-tipped designs, offering flexibility across varying production requirements.

To ensure peak performance across different aluminum machining conditions, ISCAR’s cutting tool grades are formulated for specific applications. These include IC20, an uncoated carbide grade for medium to high cutting speeds; IC04, a hard submicron carbide for titanium, high-temperature alloys, and aluminum; and IC07, another hard submicron carbide suitable for similar applications at medium to high speeds. The ID5 grade features a PCD brazed tip for very high cutting speeds, while IC1520 is DLC-coated to extend tool life during medium to high-speed aluminum machining.

In addition, ISCAR places special emphasis on the quality of the cutting edge of the inserts. Most of ISCAR’s aluminum machining inserts are precision-ground to be extremely sharp, with positive edge geometries specifically designed to prevent material buildup on the cutting edge. Since aluminum is known to be a highly adhesive material during machining, these features ensure a clean, smooth, and uninterrupted cutting process. These are unique grinding profiles developed by ISCAR, providing a significant advantage in achieving high-quality, stable machining results.

Furthermore, ISCAR’s aluminum inserts are supplied with a polished top surface, which plays a critical role in facilitating smooth chip flow and preventing chip adhesion. This polished finish reduces friction between the chip and the insert surface, helping to evacuate chips more efficiently and maintain a clean cutting zone. This contributes to a softer, cleaner cut and minimizes the risk of built-up edge formation, an essential factor when machining sticky materials like aluminum.

As vehicle design trends evolve, the demand on aluminum wheel manufacturers will continue to rise. Faster production cycles, tighter tolerances, and flawless finishes are now industry norms. ISCAR’s integrated approach combining high cutting speeds, precision coolant delivery, rigid toolholding solutions, and advanced insert technologies gives manufacturers the competitive edge they need. By equipping production lines with ISCAR’s specialized tooling systems, aluminum wheel producers can achieve higher productivity, reduced downtime, extended tool life, and consistently superior results, securing their position in a rapidly expanding and increasingly demanding global market.