In machining aerospace components, the main challenges relate to component materials. Titanium, high-temperature superalloys (HTSA), and creep-resisting steel are difficult to cut and machining is a real bottleneck in the whole aircraft supply chain. Poor machinability of these materials results in low cutting speeds, which significantly reduces productivity and shortens tool life. Both these factors are directly connected with cutting tools. In fact, when dealing with hard-to-machine typical aerospace materials, cutting tool functionality defines the existing level of productivity. The truth is, cutting tools in their development lag machine tools, and this development gap limits the capabilities of leading-edge machines in the manufacturing of aerospace components.

Modern aircraft, especially unmanned aerial vehicles (UAV), feature a considerably increased share of composite materials. Effective machining composites demand specific cutting tools, which is the focus of a technological leap in the aerospace industry.

Aircraft-grade aluminum continues to be a widely used material for fuselage elements. It may seem that machining aluminum is simple, however, selecting the right cutting tool is a necessary key to success in high-efficiency machining of aluminum.

A complex part shape is a specific feature of the turbine engine technology. Most geometrically complicated parts of aero engines work in highly corrosive environments and are made from hard-to-cut materials, such as titanium and HTSA, to ensure the required life cycle. A combination of complex shape, low material machinability, and high accuracy requirements are the main difficulties in producing these parts. Leading multi-axis machining centers enable various chip removal strategies to provide complex profiles in a more effective way. But a cutting tool, which comes into direct contact with a part, has a strong impact on the success of machining. Intensive tool wear affects surface accuracy, while an unpredictable tool breakage may lead to the discarding of a whole part.

Advanced multitasking machines, Swiss-type lathes, and live tooling lathes have profoundly changed manufacturing small-size parts of various hydraulic and pneumatic systems, actuators, and accessories, which are used in aircrafts. Consequently, the aerospace industry requires more and more cutting tools that are designed specifically for such machines to achieve maximum machining efficiency.

A cutting tool – the smallest element of a manufacturing system – turns into a key pillar for substantially improved performance. Therefore, aerospace part manufacturers and machine tool builders are waiting for innovative solutions for a new level of chip removal processes from their cutting tool producers. The solution targets are evident: more productivity and more tool life. Machining complex shapes of specific aerospace parts and large-sized fuselage components demand a predictable tool life period for reliable process planning and a well-timed replacement of worn tools or their exchangeable cutting components.

The cutting tool manufacturer has a limited choice of sources for finding an ideal solution and may only have cutting tool materials, a cutting geometry, and an intelligent robust design as the main instruments to progress. However, despite these limited choices, the cutting tool manufacturer continues all efforts to provide a new generation of tools to meet the growing requirements of the aerospace industry. COVID 19 has seriously slowed down industry development, but this does not make the industry demands any less actual. The latest tool designs are good evidence of the cutting tool manufacturer's response to the demand for aerospace component production.

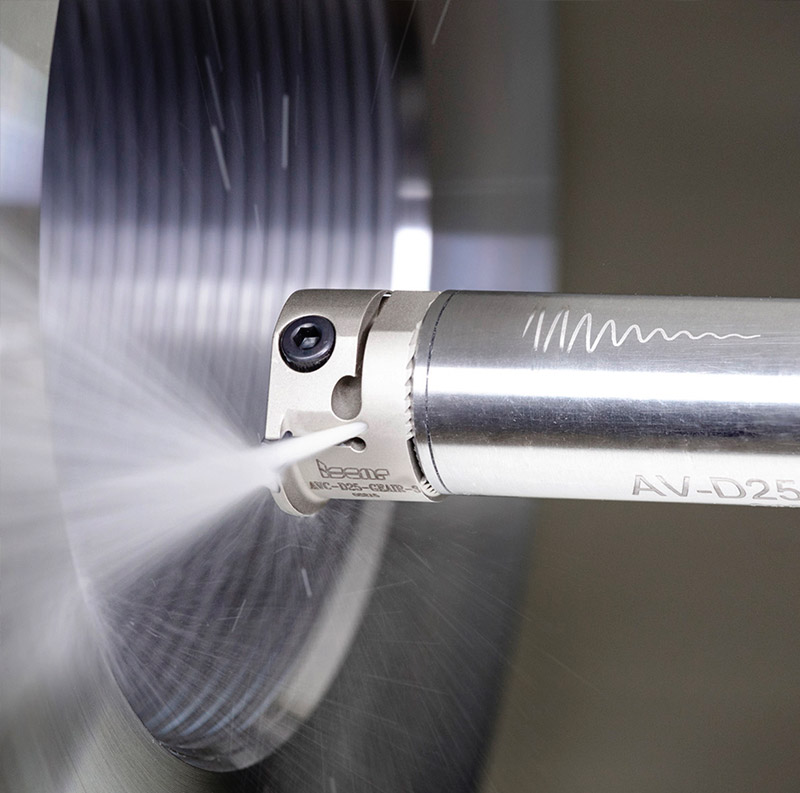

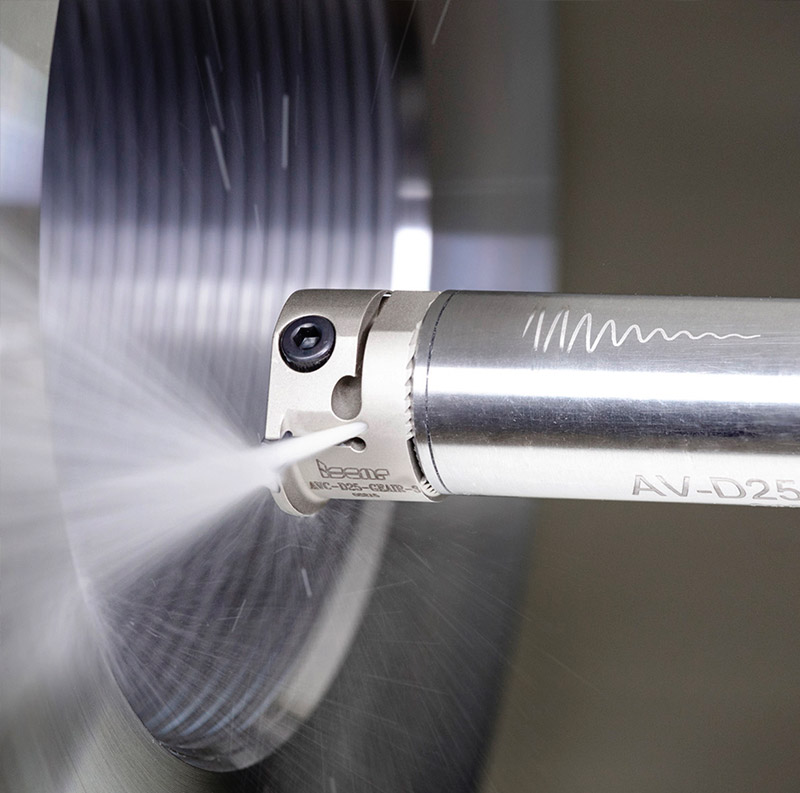

Coolant jet

In machining titanium, HTSA and creep-resisting steel, high pressure cooling (HPC) is an efficient tool for improving performance and increasing productivity. Pinpointed HPC significantly reduces the temperature at the cutting edge, ensures better chip formation and provides small, segmented chips. This contributes to higher cutting data and better tool life when compared with conventional cooling methods. More and more intensive applying HPC to machining difficult-to-cut materials is a clear trend in manufacturing aerospace components. Understandably, cutting tool manufacturers consider HPC tooling an important direction of development.

ISCAR, one of leaders in cutting tool manufacturing, has a vast product range for machining with HPC. In the last year, ISCAR has expanded its range by introducing new milling cutters carrying "classical" HELI200 and HELIMILL indexable inserts with 2 cutting edges (Fig. 1). This step brings an entire page of history to ISCAR's product line.

In the 1990’s, ISCAR introduced the HELIMILL – a family of indexable milling tools, which carried inserts with a helical cutting edge. The new design provides constant rake and relief angles along a mill cutting edge and results in a smooth and light cut with a significant reduction in power consumption. The HELIMILL principle turned into a recognized concept in the design of the 90° indexable milling cutters.

The HELIMILL was modified and underwent changes which led to additional milling families and inserts with more cutting edges. The excellent performance and its close derivatives of the original tools ensured their phenomenal popularity in metalworking. Therefore, by adding a modern HPC tool design to the proven HELIMILL family was a direct response to customer demand and the next logical tool line to develop.

In Turning, ISCAR considerably expanded its line of assembled modular tools comprising of bars and exchangeable heads with indexable inserts. With the use of a serrated connection, these tools fit a wide range of heads with a range of different insert geometries, including threading and standard ISO turning inserts for different applications for greater flexibility.

The bars have both traditional and anti-vibration designs and differ by their adaptation: cylindrical or polygonal taper shank. A common feature for the nodular tools is the delivery of internal coolant to be supplied directly to the required insert cutting edge (Fig. 2). Depending on the diameter of a cylindrical-shank tool, the maximum coolant pressure varies from 30 to 70 bars, while the tools with polygonal taper shank facilitate ultra HPC at a pressure of up to 300 bars. The efficient distribution of coolant increases the insert’s tool life by reducing the temperature and improving chip control and chip evacuation; substantially increasing this application line in the aerospace industry.

Drilling solutions

Machining composite materials is filled with various traps and pitfalls. High abrasiveness of composites intensifies wear rate which shortens tool life and affects the performance. Drilling is the most common cutting operation in machining composites, hence even a small improvement in functionality of drilling tools is of key importance.

ISCAR developed a range of new drills that are intended especially for composite materials. To increase abrasion resistance, these drills have a cutting part made from extra hard polycrystalline diamond (PCD) or diamond coating. Depending on the drill diameter, the PCD cutting part is known as a nib or a wafer; and in both cases is suitable for regrinding up to 5 times. The CVD diamond-coated solid carbide drills are attractive because of another specific design feature: the wavy shape of main cutting edges. In machining composite materials, a tool produces more chattering than a cutting effect. The wavy shape of the cutting edge considerably reduces delamination and burrs, especially when drilling carbon fiber reinforced plastics (CFRP) and carbon laminates.

In addition to composites, the diamond-coated drills are suitable for machining other high-abrasive engineering materials. If necessary, these drills can be delivered with optional tool through coolant holes.

Drilling deep, small-in-diameter holes is a common operation in manufacturing aerospace components. ISCAR's new solid carbide drills in the diameter range of 3-10 mm (0.125"-0.391") (Fig. 3) are intended specifically for such an operation. The combination of a split point geometry, a double-margin design, polished flutes, a multi-layer coating and coolant holes provides a noteworthy tool family for effective one-pass drilling holes with a depth of up to 50 hole diameters in difficult-to-cut austenitic and creep-resisting steels and ferrum-based alloys.

For any complexity

Airfoils of aero-engine turbines and compressors, impellers, and integrally bladed rotors (IBR) have a complex shape that is defined by aerodynamic requirements. New developments, which are directed on improving aero-engine efficiency, add to this complexity. Advancement of technology brought new methods for producing formed parts, in particular 3D printing, which significantly diminishes material stock for chip removal. However, machining remains the most common method for the final shaping method in manufacturing geometrically complex aerospace components. The progress in 5-axis machining and CAD/CAM systems has enriched the manufacturer's solution pool to overcome difficulties in component production.

Barrel-shaped milling cutters have good prospects in 5-axis machining of aerospace components with complex surfaces. ISCAR has developed a series of barrel-shaped cutters of 8 - 16 mm (.312" - .500") in diameter in two designed configurations: solid carbide endmills and exchangeable heads with a Multi-Master threaded connection. The introduction of these tools into the machining processes is a major advantage of intensifying blade manufacturing.

Promising multitasking

Effectiveness of chip-removal processing on compact multi-tasking machines and Swiss-type lathes depends largely on correct tool selection. Demands to increase productivity require maximum tool holding stiffness and limited working space to minimize tool overhang.

Recently, ISCAR introduced NEOCOLLET, a new tool holding family, which provides an alternative to clamping tools with spring collets. One of the typical toolholders in this family has a tapered shank that can be mounted in a collet chuck directly (Fig. 4), ensuring a rigid and reliable connection to improve tool performance. The new family includes the holders for ISCAR T-SLOT exchangeable slot and face milling heads from cemented carbide.

As mentioned, applying high pressure cooling can substantially change machining results especially when deal with titanium, HTSA and difficult-to-cut stainless steel – the main materials for aircraft hydraulic and pneumatic systems and light-sized accessories. The new turning tools with a square shank and a reliable screw clamping mechanism for 55° rhombic insert facilitate HPC in longitudinal, face and profile turning operations on small-diameter parts (Fig. 5).

The given examples illustrate how the toolmaker tries to find more effective solutions to meet the new requirements of the aerospace industry. A slowdown in the industry growth and reduction of aircraft production caused by COVID 19 has not diminished the toolmaker's focus on their needs for partners. On the contrary, new progressive cutting tools have been developed and ISCAR will successfully find its new and upgraded applications in the restored aircraft production of tomorrow.

[Fig. 1]

[Fig. 1]

[Fig. 2]

[Fig. 2]

[Fig. 3]

[Fig. 3]

[Fig. 4]

[Fig. 4]

[Fig. 5]

[Fig. 5]