Page 19 - machining_titanium_05_2019

P. 19

Cutting in unfavorable or unstable conditions? Heavy or heavy-duty machining?

“Cutting in unfavorable or unstable conditions” – which is correct? The meaning of these two

definitions is confusing sometimes. “Unfavorable conditions” relate to the following cases of

cutting: skinned workpiece, variable machining allowance (material to be removed) that leads

to changing the depth of cut, significant impact load, surfaces with high-abrasive inclusions, MILLING TITANIUM

chatter. “Unstable conditions” characterize low stability of a complete system (machine tool,

workpiece holding fixture, cutting tool, workpiece) caused by poor tool and/or workpiece

holding, non-rigid machine tool, high tool overhang, thin-walled workpiece, etc. Despite the

gap in definitions, the conditions are in a cause-and-effect relationship: for example, low

technological rigidity contributes to increased vibrations and thus worsens cutting conditions.

Therefore, in some instances the above definitions are considered as synonyms.

Regarding heavy and heavy-duty machining. “Heavy-duty” means significant mechanical

and thermal loading of the technological system and its separate components, including the

cutting tool, due to removing considerable allowance, extreme cutting data, etc. “Heavy” is

used with respect to machining large-sized heavy-weight parts on powerful heavy machine

tools. So, “heavy-duty” specifies the mode of machining, a degree of loading the tool;

and “heavy” is used more to define dimensions of the machined parts and metal cutting

tools. Note that a small-size cutting tool can work in heavy-duty cycles under extremely

high load and that producing large parts may require applying the small tool as well.

A “golden rule” for manufacturer engineer, process planner and machinist says: “Avoid

heavy-duty machining in unfavorable conditions especially if your technological system is

unstable!” This holds for all metalworking branches and among them heavy industry.

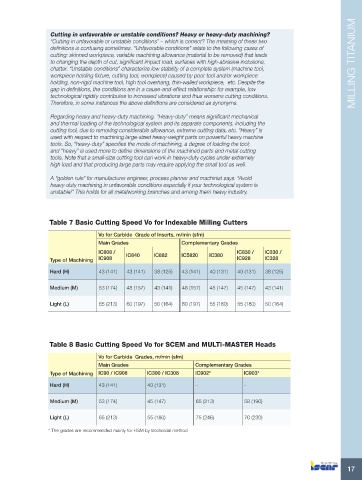

Table 7 Basic Cutting Speed Vo for Indexable Milling Cutters

Vo for Carbide Grade of Inserts, m/min (sfm)

Main Grades Complementary Grades

IC808 / IC840 IC882 IC5820 IC380 IC830 / IC330 /

Type of Machining IC908 IC928 IC328

Hard (H) 43 (141) 43 (141) 38 (125) 43 (141) 40 (131) 40 (131) 38 (125)

Medium (M) 53 (174) 48 (157) 43 (141) 48 (157) 45 (147) 45 (147) 43 (141)

Light (L) 65 (213) 60 (197) 50 (164) 60 (197) 55 (180) 55 (180) 50 (164)

Table 8 Basic Cutting Speed Vo for SCEM and MULTI-MASTER Heads

Vo for Carbide Grades, m/min (sfm)

Main Grades Complementary Grades

Type of Machining IC90 / IC908 IC300 / IC308 IC902* IC903*

Hard (H) 43 (141) 40 (131) - -

Medium (M) 53 (174) 45 (147) 65 (213) 58 (190)

Light (L) 65 (213) 55 (180) 75 (246) 70 (230)

* The grades are recommended mainly for HSM by trochoidal method

17