Page 6 - FAST_FEED_MILL_Brochure_INCH_2022

P. 6

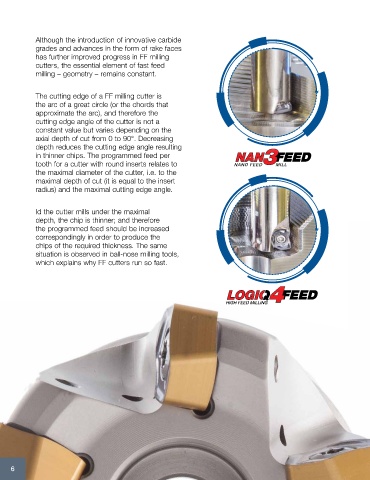

Although the introduction of innovative carbide

grades and advances in the form of rake faces

has further improved progress in FF milling

cutters, the essential element of fast feed

milling – geometry – remains constant.

The cutting edge of a FF milling cutter is

the arc of a great circle (or the chords that

approximate the arc), and therefore the

cutting edge angle of the cutter is not a

constant value but varies depending on the

axial depth of cut from 0 to 90°. Decreasing

depth reduces the cutting edge angle resulting

in thinner chips. The programmed feed per

tooth for a cutter with round inserts relates to

the maximal diameter of the cutter, i.e. to the

maximal depth of cut (it is equal to the insert

radius) and the maximal cutting edge angle.

Id the cutter mills under the maximal

depth, the chip is thinner; and therefore

the programmed feed should be increased

correspondingly in order to produce the

chips of the required thickness. The same

situation is observed in ball-nose milling tools,

which explains why FF cutters run so fast.

6