Page 15 - HOLE_MAKING_CATALOG_INCH_2022_P237-P372

P. 15

USER GUIDE

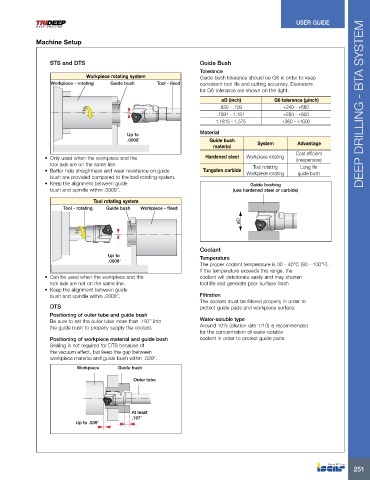

Machine Setup

STS and DTS Guide Bush

Tolerance

Workpiece rotating system Guide bush tolerance should be G6 in order to keep

Workpiece - rotating Guide bush Tool - fixed consistent tool life and cutting accuracy. Diameters

for G6 tolerance are shown on the right.

øD (inch) G6 tolerance (μinch)

.630 - .709 +240 - +680 DEEP DRILLING - BTA SYSTEM

.7091 - 1.181 +280 - +800

1.1815 - 1.575 +360 - +1000

Up to Material

.0008” Guide bush System Advantage

material

Cost efficient

• Only used when the workpiece and the Hardened steel Workpiece rotating (inexpensive)

tool axis are on the same line. Tool rotating Long life

• Better hole straightness and wear resistance on guide Tungsten carbide Workpiece rotating guide bush

bush are provided compared to the tool rotating system.

• Keep the alignment between guide Guide bushing

bush and spindle within .0008”. (use hardened steel or carbide)

Tool rotating system

Tool - rotating Guide bush Workpiece - fixed

¿D

Coolant

Up to Temperature

.0008”

The proper coolant temperature is 30 - 40°C (90 - 100°F).

If the temperature exceeds this range, the

• Can be used when the workpiece and the coolant will deteriorate easily and may shorten

tool axis are not on the same line. tool life and generate poor surface finish.

• Keep the alignment between guide

bush and spindle within .0008”. Filtration

The coolant must be filtered properly in order to

DTS protect guide pads and workpiece surface.

Positioning of outer tube and guide bush

Be sure to set the outer tube more than .197” into Water-soluble type

the guide bush to properly supply the coolant. Around 10% (dilution rate 1/10) is recommended

for the concentration of water-soluble

Positioning of workpiece material and guide bush coolant in order to protect guide pads.

Sealing is not required for DTS because of

the vacuum effect, but keep the gap between

workpiece material and guide bush within .039”.

Workpiece Guide bush

Outer tube

At least

.197”

Up to .039”

251