Machining Aluminum: Is It Really That Easy?

Aluminum possesses unique qualities and can transform from white to silver. It is incorrodible like gold, as tenacious as iron, as fusible as copper, and as light as glass. It is easily workable and widely found in nature, as it is based on alumina, which forms the basis of most rocks. Aluminum is three times lighter than iron; in short, it seems to have been created expressly to furnish projectile material! This characteristic of aluminum, described by Jules Verne, the French novelist, poet, and playwright many years ago, explains why aluminum and its alloys have become essential engineering materials. Its lightweight nature, good formability and machinability, and high corrosion resistance have made aluminum extremely popular in the aerospace, automotive, and packaging industries, as well as in resin mold manufacturing, homeware, and other fields. The use of pure aluminum is limited. In most industrial applications, aluminum is used in the form of alloys with various alloying elements, typically copper, magnesium, silicon, zinc, and others. Therefore, when discussing the machining of aluminum, it usually refers to cutting aluminum alloys.

Aluminum is considered a material with good machinability. There is a strong belief that machining aluminum does not cause any particular problems. “Take a sharp cutting tool and machine aluminum as fast as you can” – this tenet is very common in the manufacturing environment. Indeed, aluminum is one of the most machinable engineering materials. Hence, the main task when machining aluminum, as manufacturers perceive, is to ensure maximum productivity based on the capabilities of the machine tools. This is correct; however, your cutting tool should not only allow for this but also facilitate reasonable tool life and not break shortly thereafter. So, what are the main problems in machining aluminum and what are the requirements for a cutting tool to solve these problems?

Although aluminum has good machinability, cutting aluminum presents challenges. Here are some of them:

- Difference in Machinability

Machining aluminum depends on several factors, one of which is its chemical composition. For example, the silicon percentage is an important aspect that affects tool life. Another factor is the fabrication method: generally, there are two main groups of aluminum alloys – cast and wrought, with the latter representing the majority of alloys. These groups can be further divided into heat-treatable and non-heat-treatable alloys. Additionally, there has been an increase in the usage of sintered aluminum alloys in the industry. All of these factors influence machinability, which can vary within relatively broad limits. Some alloys exhibit machinability that is approximately half that of commercially pure aluminum. - Chip Evacuation

When cutting, aluminum generates long, curly chips that can wrap around the cutting tool and machined workpiece. This may cause problems with chip evacuation and worsen the surface finish. - Built-up edge

Aluminum tends to form built-up edge (BUE) on the cutting tool, which negatively affects surface finish and machining accuracy. High thermal conductivity of aluminum contributes to the BUE development. - Surface Quality

The sticking of aluminum to the cutting tool results in galling that diminishes the quality of the machined surface. - Machining Stability

Low stiffness of aluminum can be a source of vibration, reducing machining results.

Seemingly simple machining of aluminum relates to several issues, which require appropriate solutions. The cutting tool has no small, probably even critical, part to achieve success in this process. The development of cutting tools for machining aluminum includes several directions.

Cutting Material

Advanced carbide grades, including coated ones and extra-hard polycrystalline diamond (PCD), allow for significantly increased performance.

Cutting Geometry

The optimized cutting geometry, which is achieved through appropriate rake and clearance angles, sharp cutting edges, the topology of chip-forming surfaces, and the shape of chip spaces, is a significant factor in improving cutting action. It ensures free chip flow and reduces the BUE phenomenon.

Tool Design

Machining aluminum involves high cutting speeds, meaning that rotating cutting tools operate at substantial rotational velocities and can experience considerable centrifugal loads. This places additional requirements on the tool’s dynamic behavior and dynamic balance, especially in the case of indexable tool designs and modular tool solutions. Effective cooling is an important factor for improving chip evacuation, eliminating galling, and diminishing BUE formation. Pinpointed coolant supply directly to the cutting zone via the tool body is a useful way to enhance cooling and lubricity in cutting operations.

Cutting tools for machining aluminum are prominently featured in the product range of ISCAR, being a leading tool manufacturer. These tools hold a significant place among the turning, milling, hole-making, and threading solutions offered by the company. In recent years, ISCAR has introduced various new designs that have enriched these products. The newcomers exemplify the development trends in tools for machining aluminum.

Diamond-like carbon (DLC) coating offers an advantageous combination of high hardness and excellent wear resistance. Additionally, the low friction ratio of DLC against aluminum considerably helps reduce adhesion and built-up edge (BUE) formation during cutting. These properties make DLC ideal for machining non-ferrous metals, particularly aluminum containing up to 12% silicon. ISCAR’s two nanocomposite DLC-coated carbide grades—IC1520 for turning and grooving inserts (Fig. 1), and IC1508 for solid end mills and parting inserts—expand the customer’s options for improving efficiency.

ISCAR’s indexable standard-range products have been enhanced with new inserts featuring cutting geometries specifically designed for machining aluminum. These include high-precision double-ended grooving inserts and double-sided ISO-type rhombic and trigon turning inserts. All of them have polished rake faces with specially shaped chipbreakers to eliminate built-up edge formation and ensure a smooth and light cut. In the solid carbide tool families, ISCAR has added new endmills with a variable flute design to improve vibration-dampening abilities.

Quick-change tooling is one of the main trends in the metalworking industry. Specifically for customers involved in the machining of aluminum wheels, ISCAR has developed a new range of quick-change modular tools for various external and internal turning operations, including profiling and undercutting, facing, and boring (Fig. 2). The system utilizes a dovetail connection and full-face contact between the cutting head with an indexable insert and the body, providing extremely high clamping forces to ensure stability and resistance to tough machining conditions.

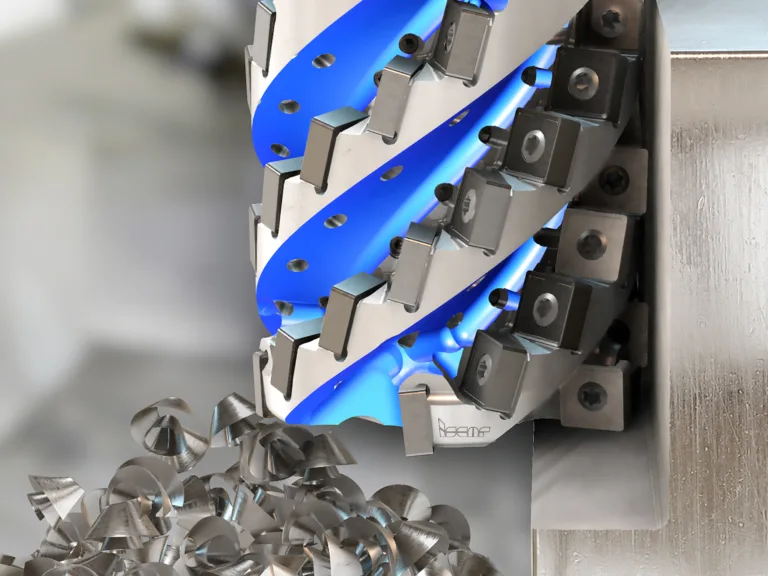

In indexable milling, ISCAR expands its HELIALU family with inserts made from a hard submicron grade to maintain the insert’s cutting-edge sharpness. The new high-accuracy inserts feature aggressively positive cutting geometry and a polished rake face, intended for milling aluminum and aluminum-lithium alloys at very high feed rates (Fig. 3).

New products have also been added to MULTI-MASTER, the popular family of versatile assembled tools with exchangeable cutting heads. These products include solid carbide three-flute 90° milling heads with chatter-resistant geometry and four-flute barrel-shaped heads, which are primarily targeted for 5-axis milling of complex surfaces.

Additive manufacturing (AM) opens new horizons for tool development. New exchangeable heads carrying indexable inserts with MULTI-MASTER and FLEXFIT threaded adaptations (Fig. 4) provide a high-pressure coolant (HPC) supply option through internal channels and outlets produced using 3D printing technologies. These channels are optimized for coolant flow using computational fluid dynamics. The threaded adaptations allow for customization based on the modularity principle of the MULTI-MASTER and FLEXFIT families, which offer a wide variety of replaceable adapters, extensions, and reducers. The heads, which are also suitable for machining with minimum quantity lubrication (MQL), significantly expand the application range for milling aluminum alloys, including abrasive ones with high silicon content.

AM enables the creation of ingenious tool configurations to meet the requirements of specific machining applications. A good example is a special boring tool with polycrystalline diamond (PCD) tipped inserts that harmoniously combines inventive design, the results of design optimization through structural analysis using the finite element method (FEM), and 3D printing capabilities (Fig. 5). So, is aluminum really that easy to machine? Probably, but only if you have truly effective tools at your disposal.