NEO ITA Guide

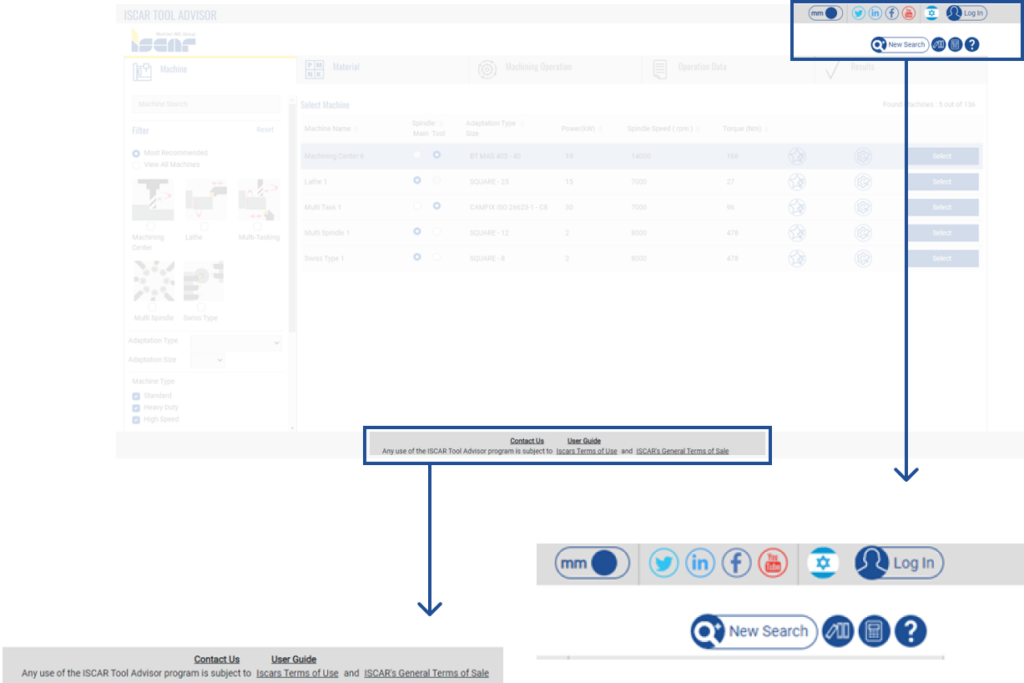

NEOITA Settings and Navigation

Place your mouse over each number feature to see the explanation

Measurement Unit Selection(Metric/Inch)

Country/Language Selection

Login for Custom Features

Create New Search

E-Catalog

Calculators Menu

Help Menu

Contact NEOITA Support

Detailed step by step user guide

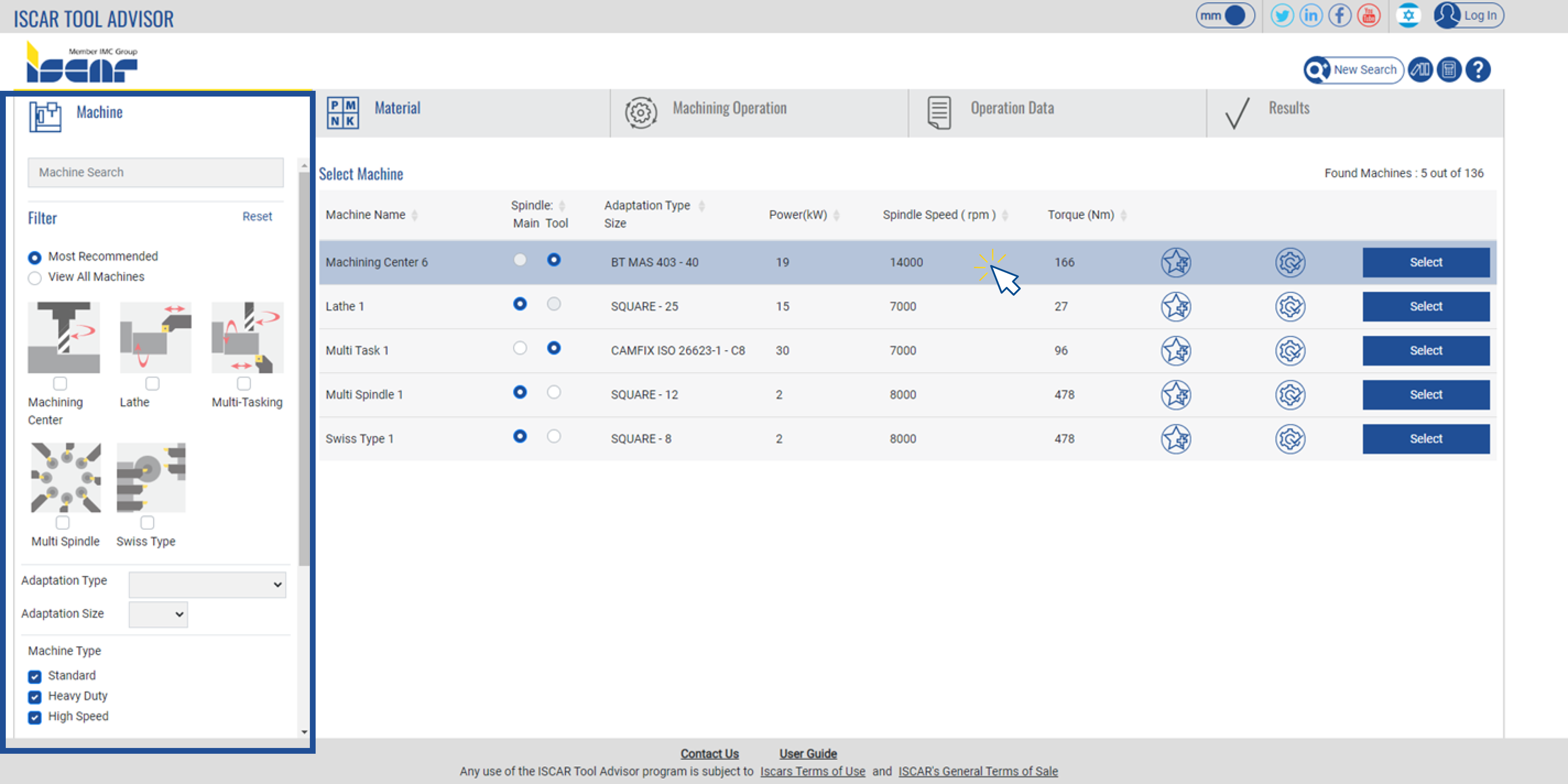

NEOITA Machine Page

Filter Panel- select machine specification (type, adaptation, adaptation size and more)

Choose the main or tool spindle if applicable

Click on the row to edit machine specifications

Add the machine to your favorites

(logging in is required)

Proceed to the materials

tab with the current parameters

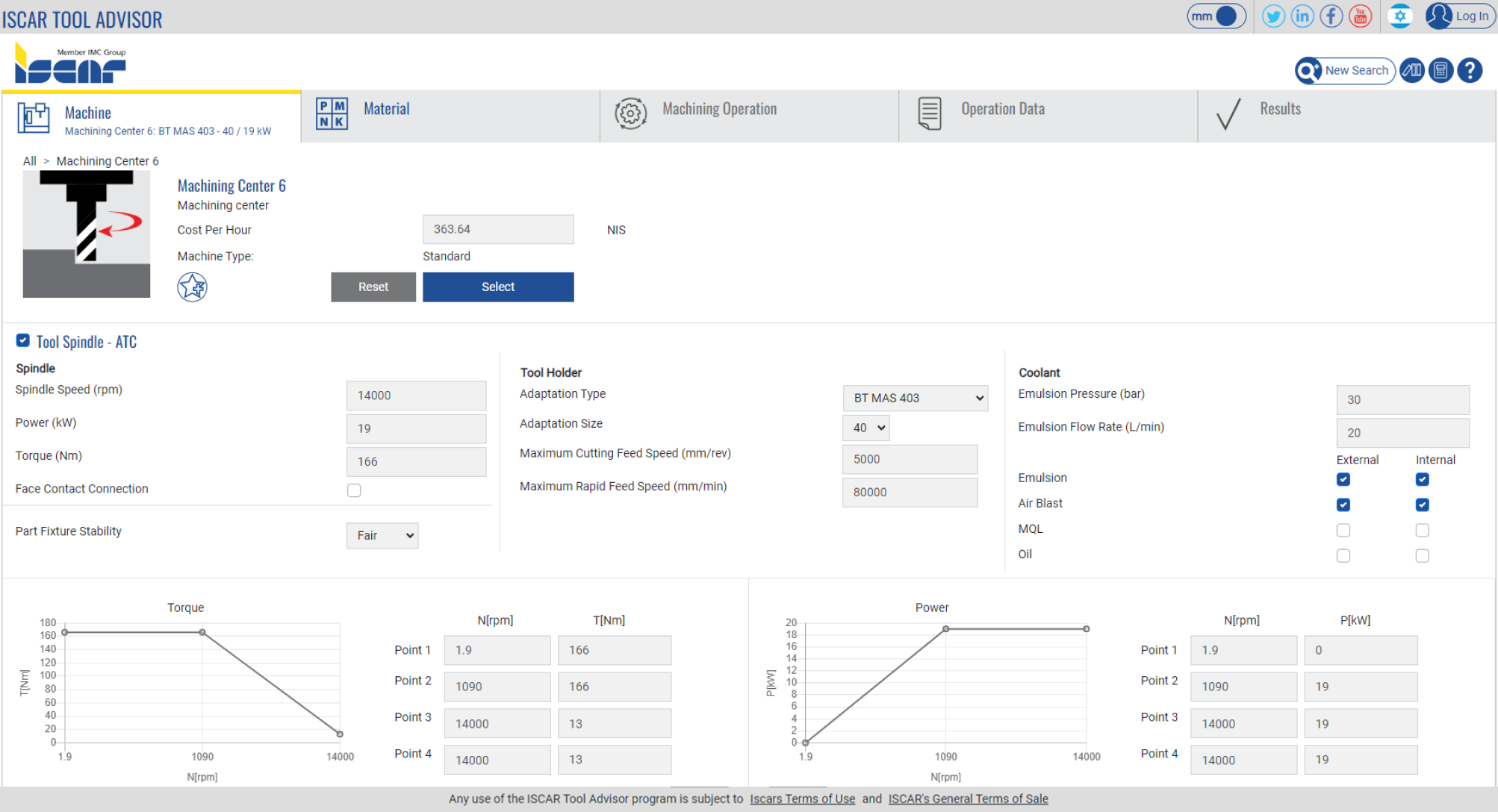

NEOITA Machine Page- Machine Parameters

Modify the machine cost per hour, spindle, Power/torque graph, tool holder and coolant parameters.

In order to save the parameters, first add the machine to the “My Machines” list by clicking on the icon ![]()

Then, the save icon![]() will appear and clicking on it will save the parameters.

will appear and clicking on it will save the parameters.

Click the “Select” button to confirm and proceed to the material tab.

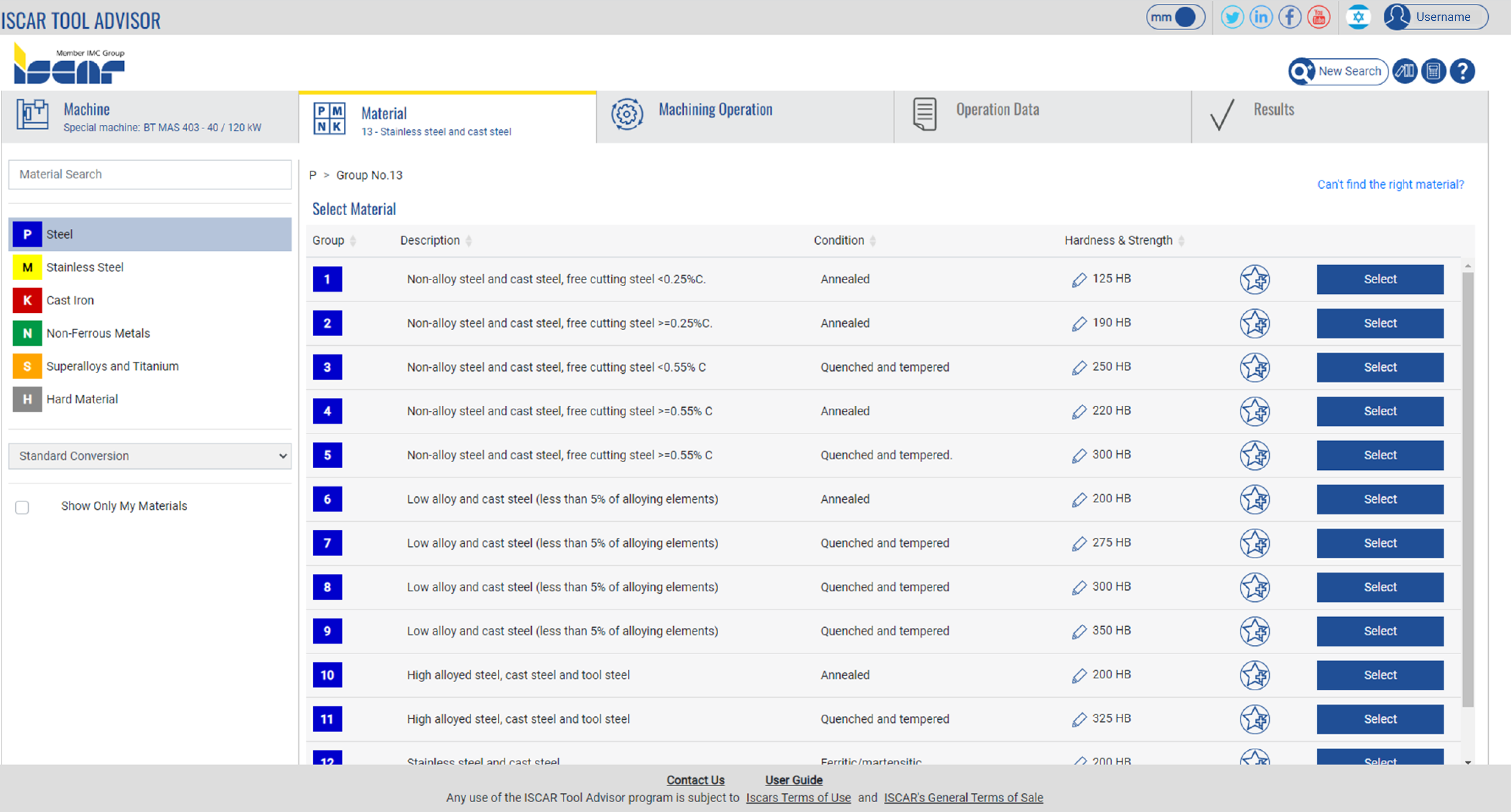

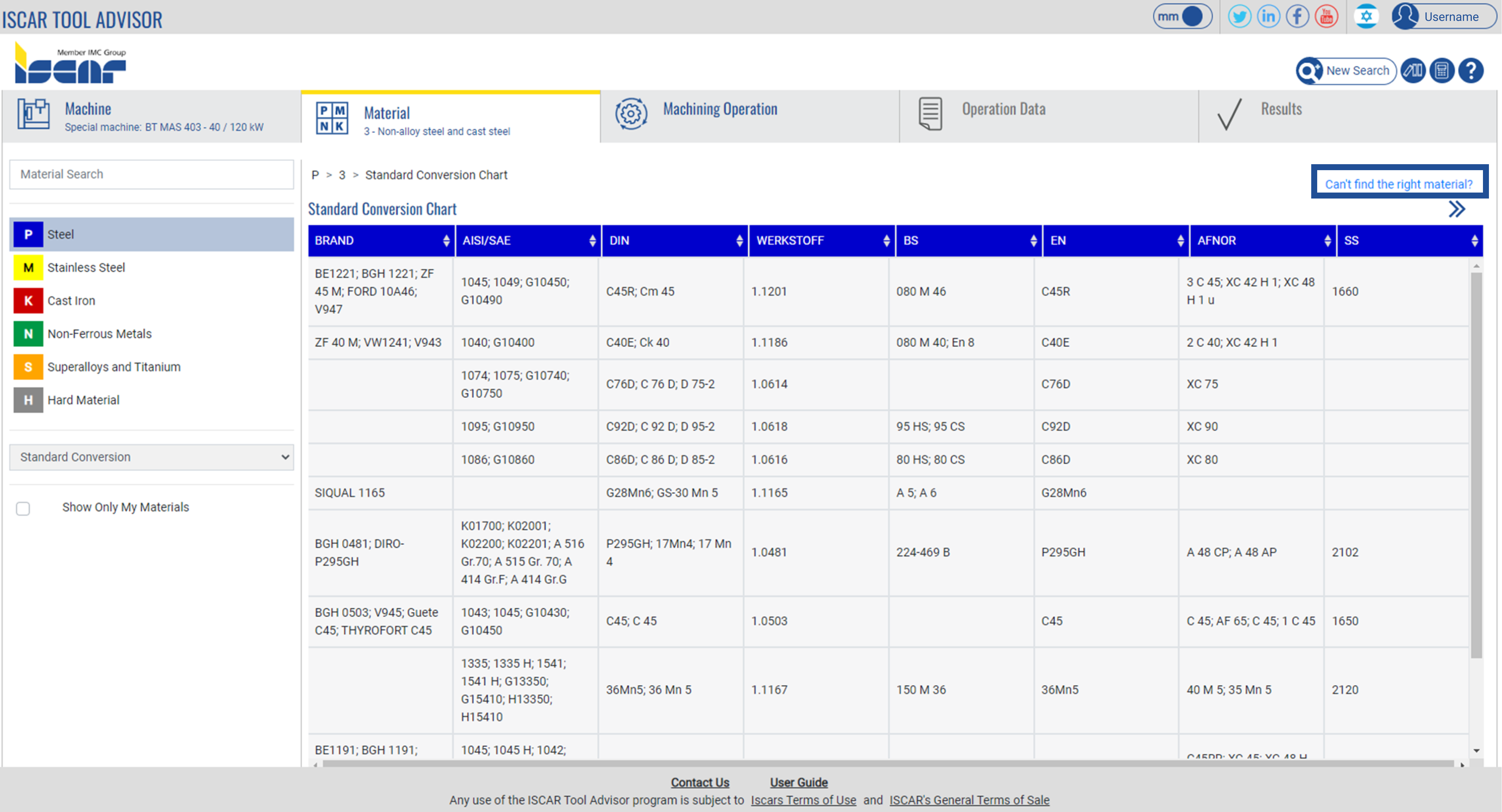

NEOITA Materials Page

Select required material from the list- toggle between ISO P/M/K/N/S/H groups and select the material by clicking on “Select”.

The materials can be filtered by standard type, material group or by the material search filed.

Materials with selected hardness can be saved with the “Add to My Materials” button ![]() , Please note that logging in is required.

, Please note that logging in is required.

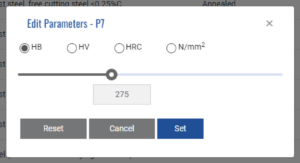

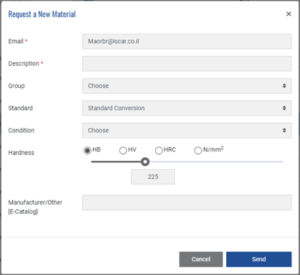

By clicking on the pencil icon ![]() , an editing pop-up will appear with the option to edit the material hardness and strength

, an editing pop-up will appear with the option to edit the material hardness and strength

NEOITA Materials Page

After clicking on the row, the standard conversion chart will open and the specific material can be chosen

Additional materials can be added to NEOITA database via “Can’t find the right material” option.

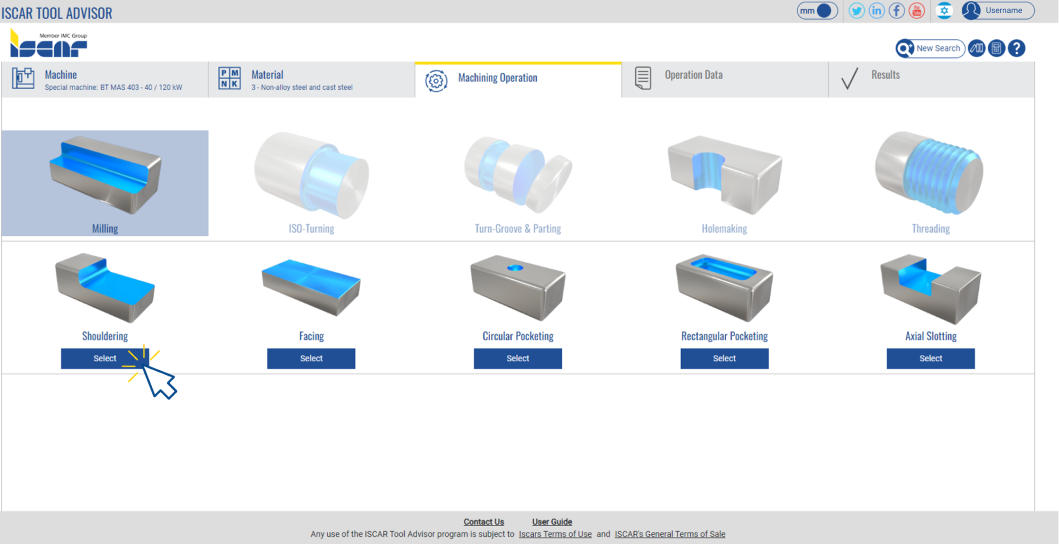

NEOITA Machining Operation Page

Select the required application type.

Please note: Application availability is based on the machine type and adaptation

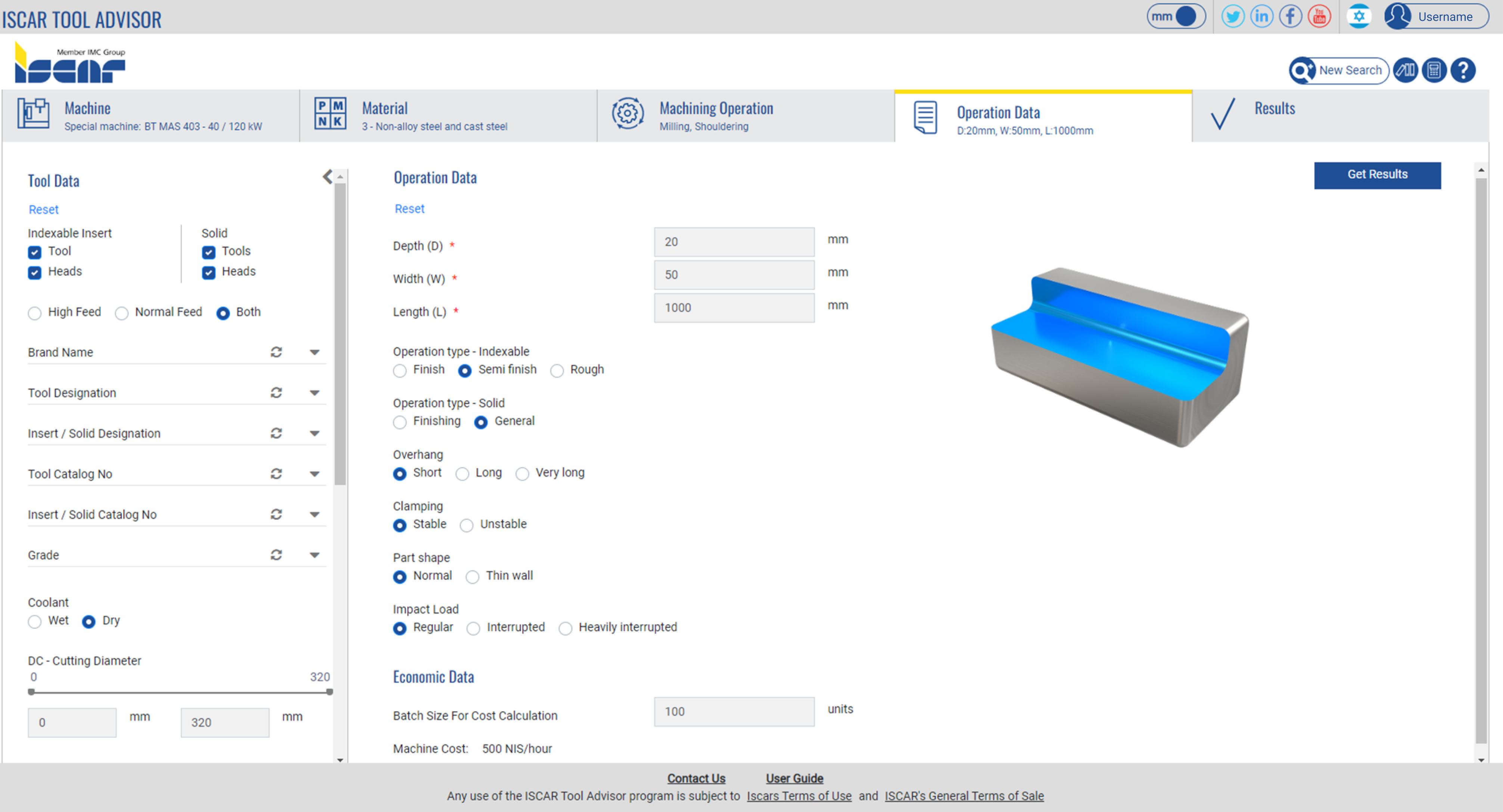

NEOITA Operation Data Page

Filter request solution by various criteria (indexable insert, solid tool, brand name, catalog number, tool diameter,

no. of flutes, etc.)

Select application geometric features, machining type and production batch size

Get Results Button

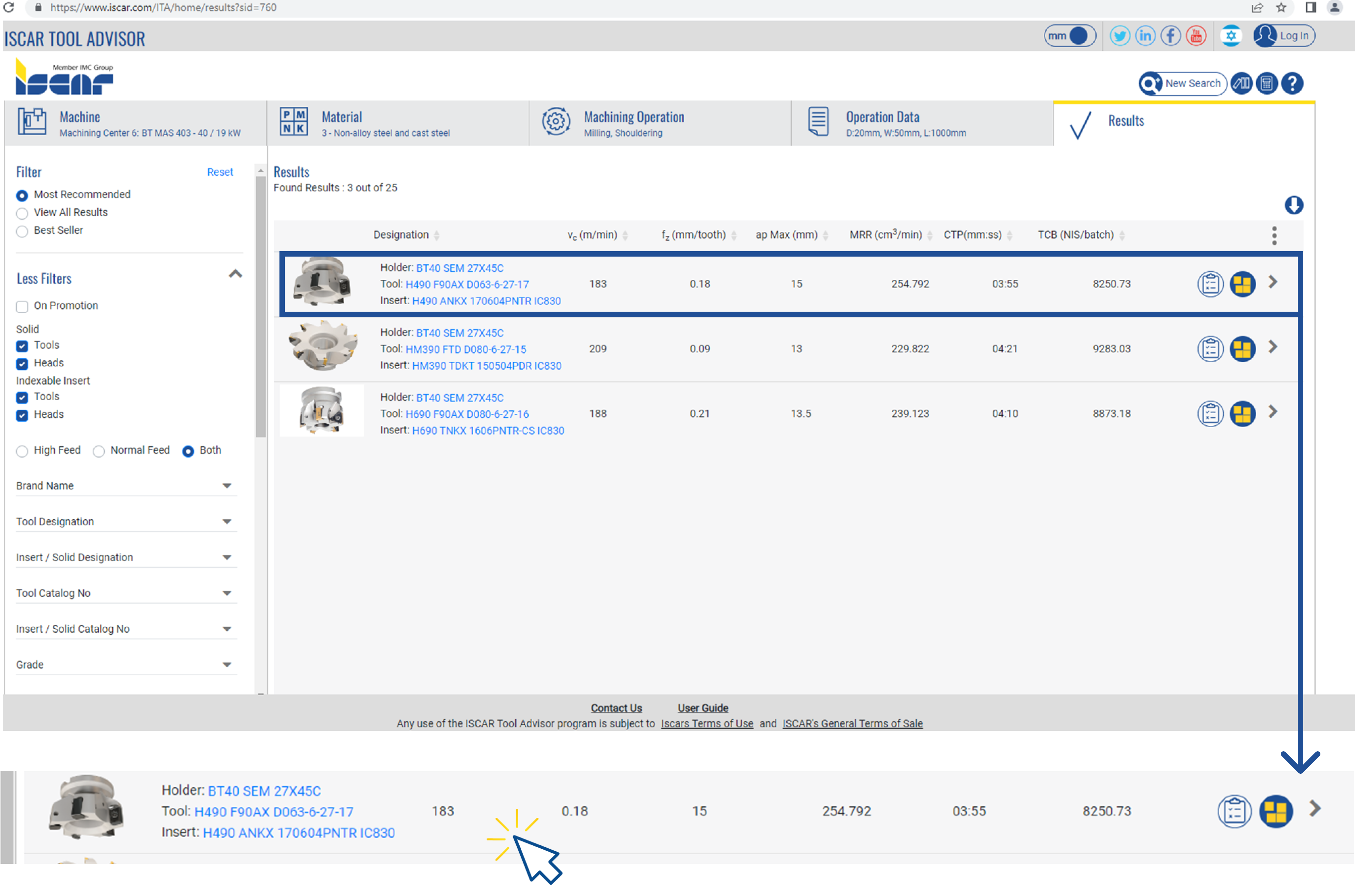

NEOITA Results Page

Filter Results-

Most Recommended - top 3 results

View All Results Available

Best Seller - sort all results by global best sellers

Advanced filters by different criteria

Results- shows applications

results that can be filtered

by different parameters (MRR, speed feed, etc.)

Select parameters from the list to compare each solution

Download results in PDF format

Links to the products on ISCAR E-Catalog

More information

More information

Stock availability-

review the selected

solution stock on

ISCAR’s main

logistic centers

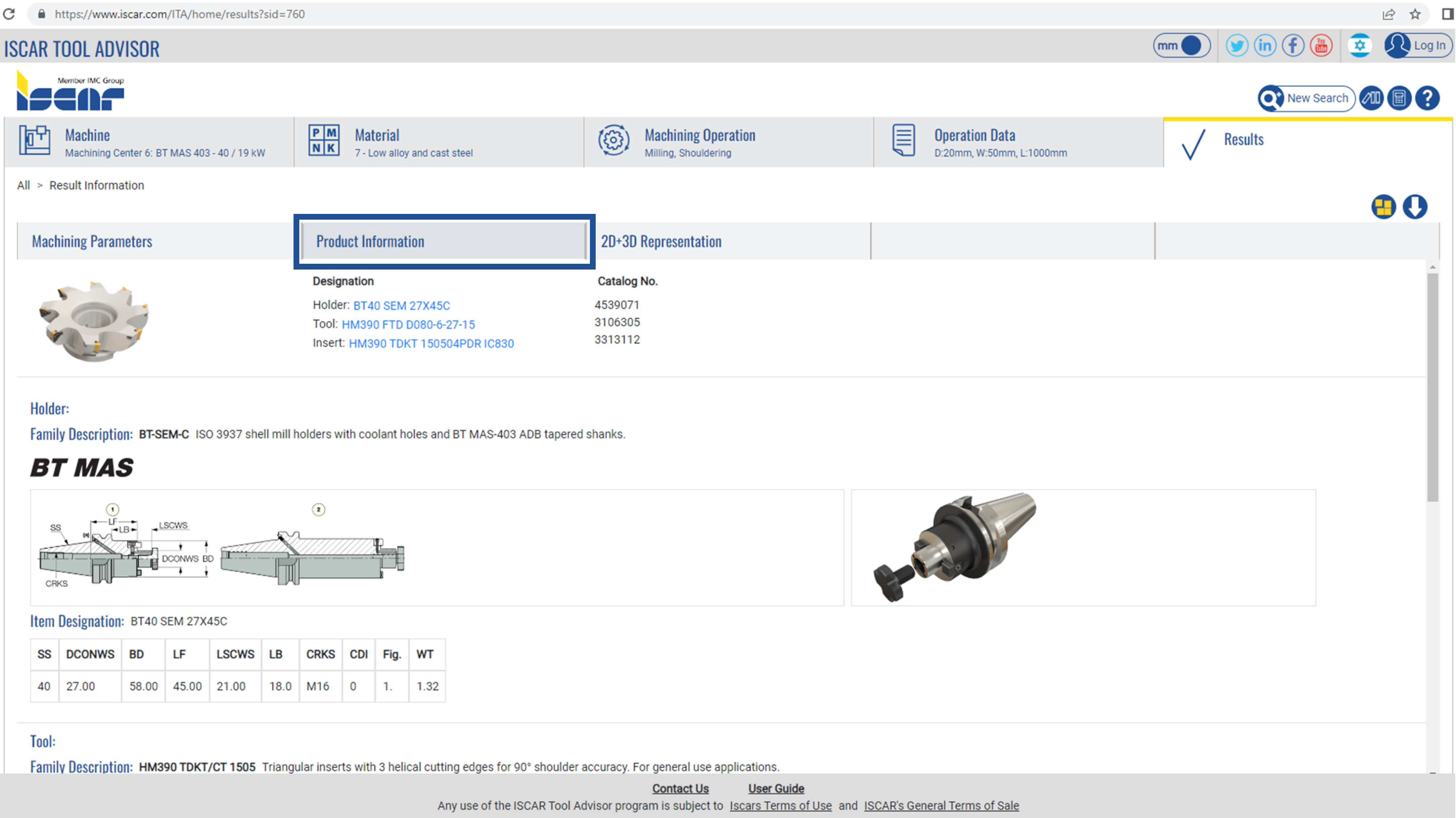

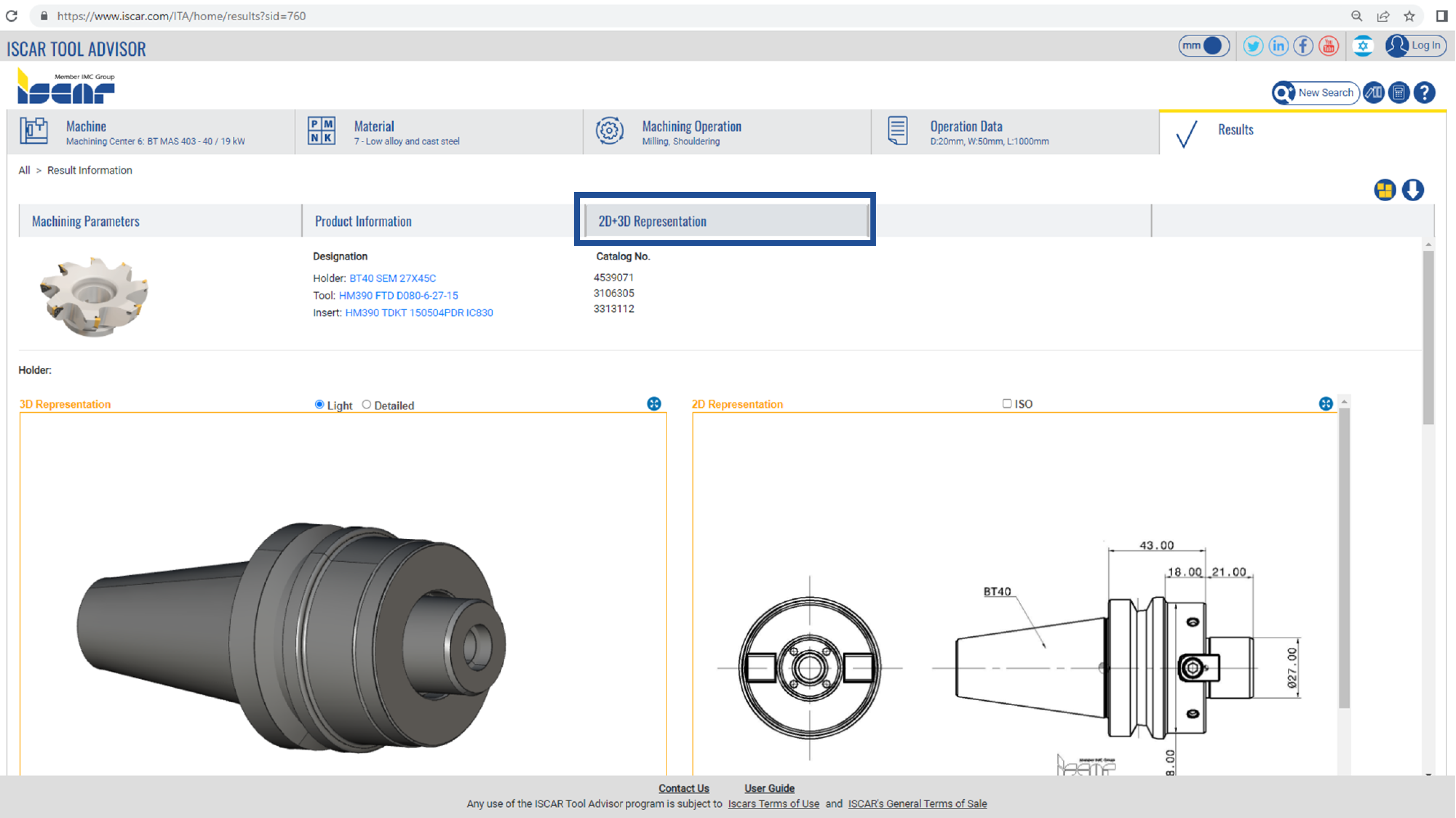

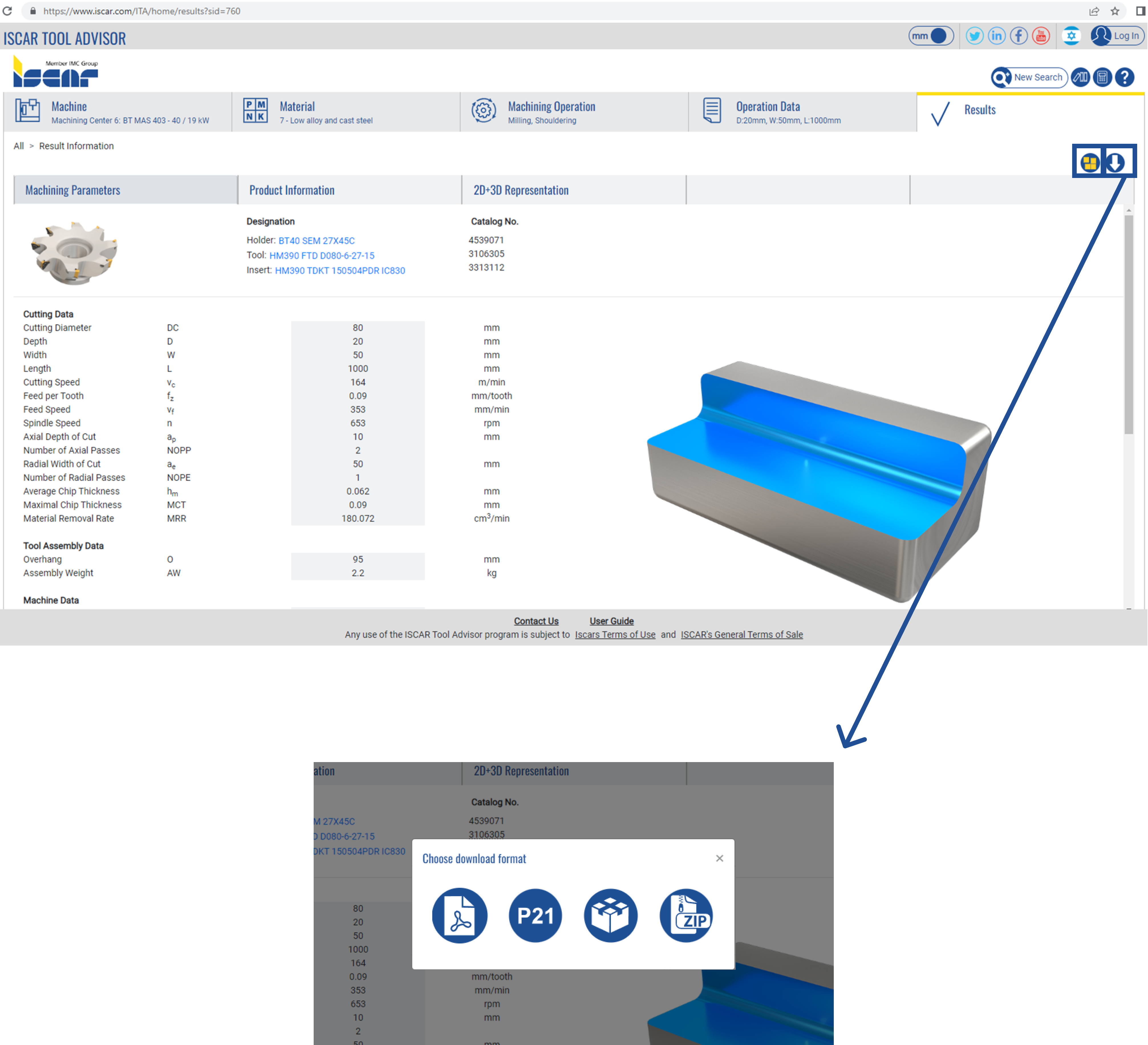

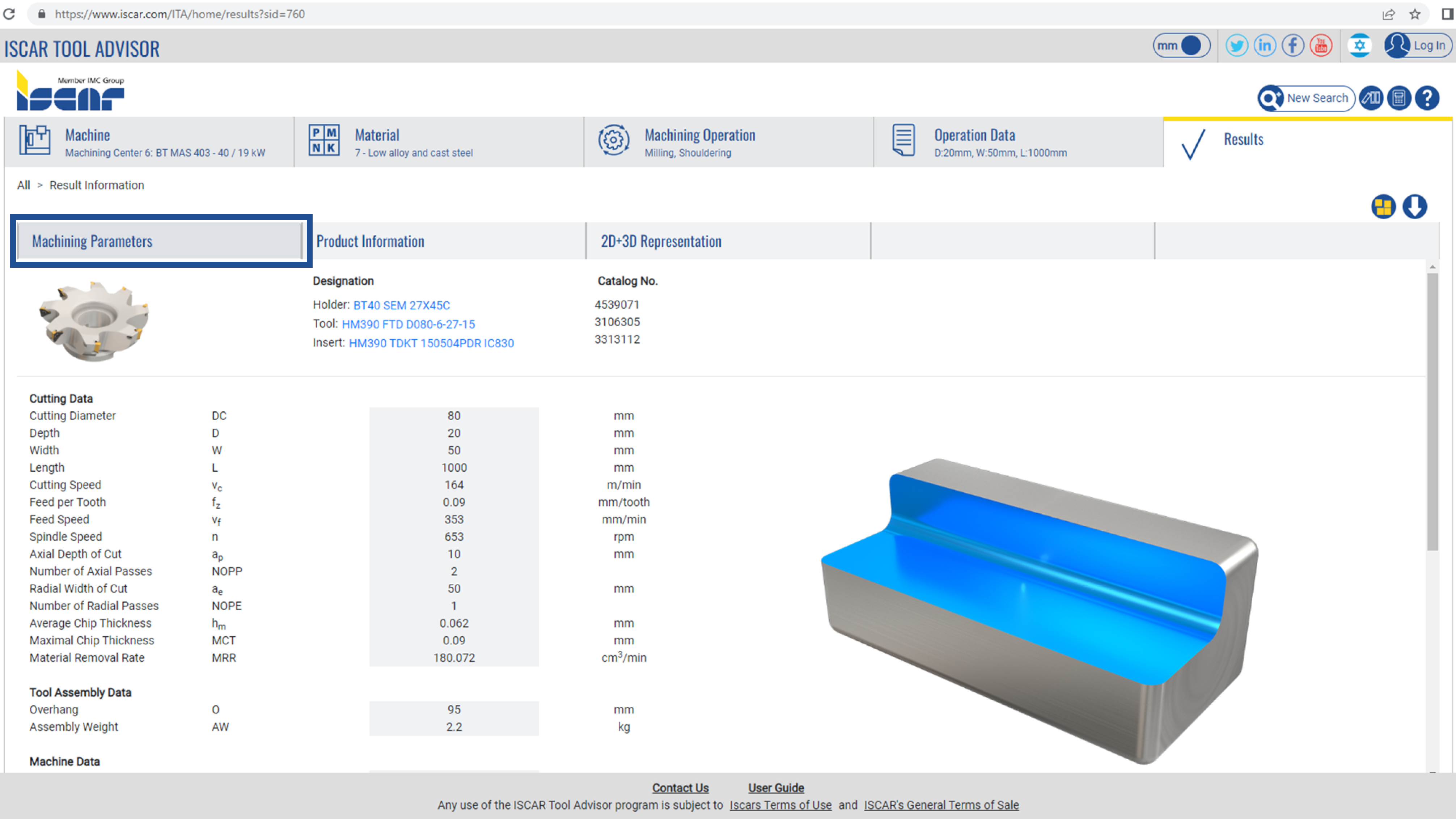

NEOITA Solution Result Information

Create Assembly - Create a 2D/3D assembly on ISCAR's eCatalog

Download Results-

Export the results as a

PDF file/ P21/ File Package/ ZIP

Machining Parameters– displays the machining parameters:

Cutting Data: Summarized machining strategy.

Tool Assembly Data: Overhang and weight information.

Machining Data: Review different machining forces.

Time and Cost: Summarized implementation cost and projected tool life.