Back in the early 2000s, the introduction of ISCAR's MULTI-MASTER system of rotating tools with interchangeable carbide heads played a significant role in the development of cutting tools. Tool assemblies with exchangeable heads were known long before ISCAR’s MULTI-MASTER. This was a product that changed the traditional view of the design concept of such systems.

Within the MULTI-MASTER product line, heads are secured by using a thread connection. Cemented carbide is a very hard and wear-resistant material and has lower impact strength when compared to high-speed steel. In a threaded carbide part, the thread is a source of stress concentrators that is crucial for tool functioning, especially under cyclic loading. Rotating tools with exchangeable carbide heads are reasonable in a relatively small diameter range, typically 6-25 mm (.25"-1.00"), which limits appropriate thread diameters and the height of a thread profile.

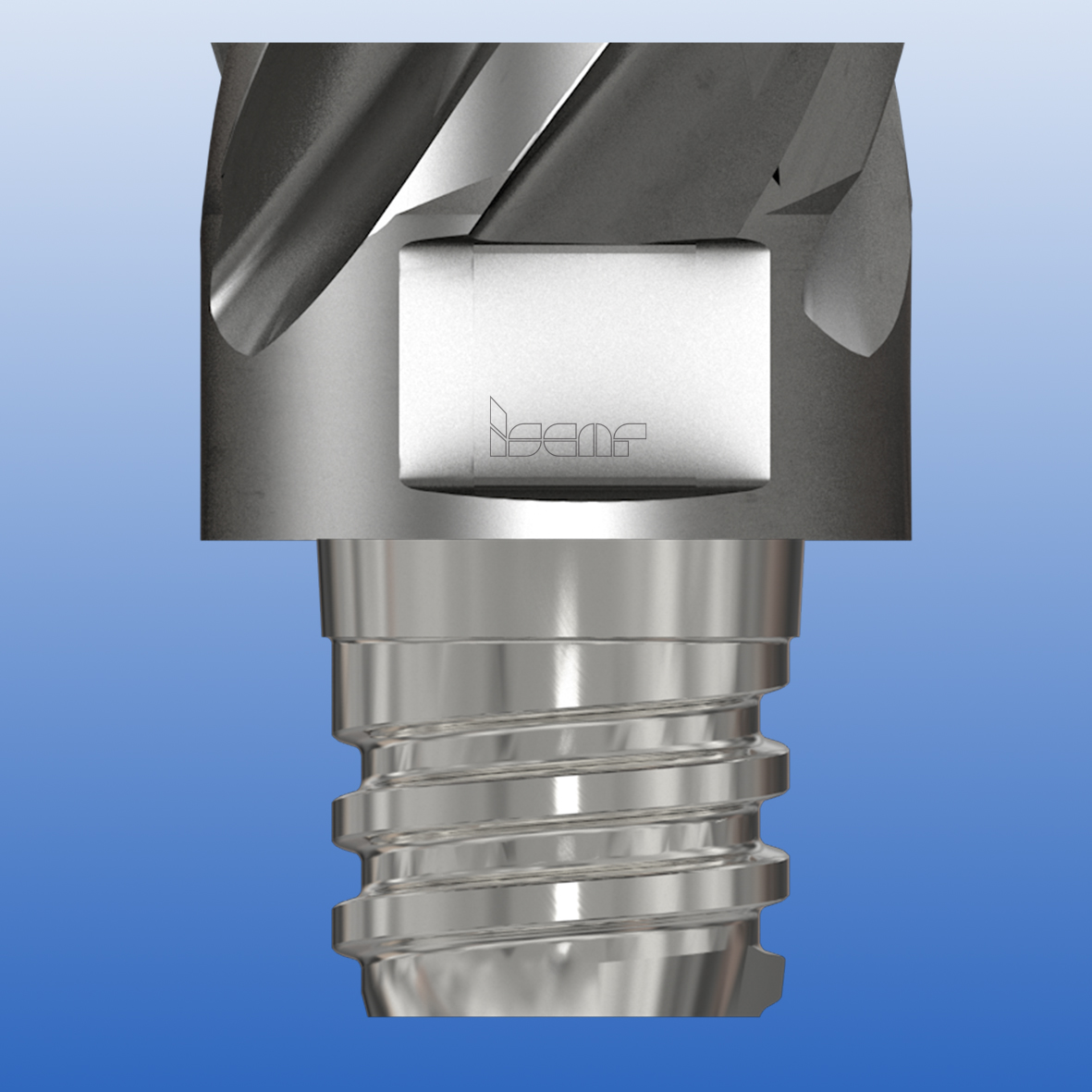

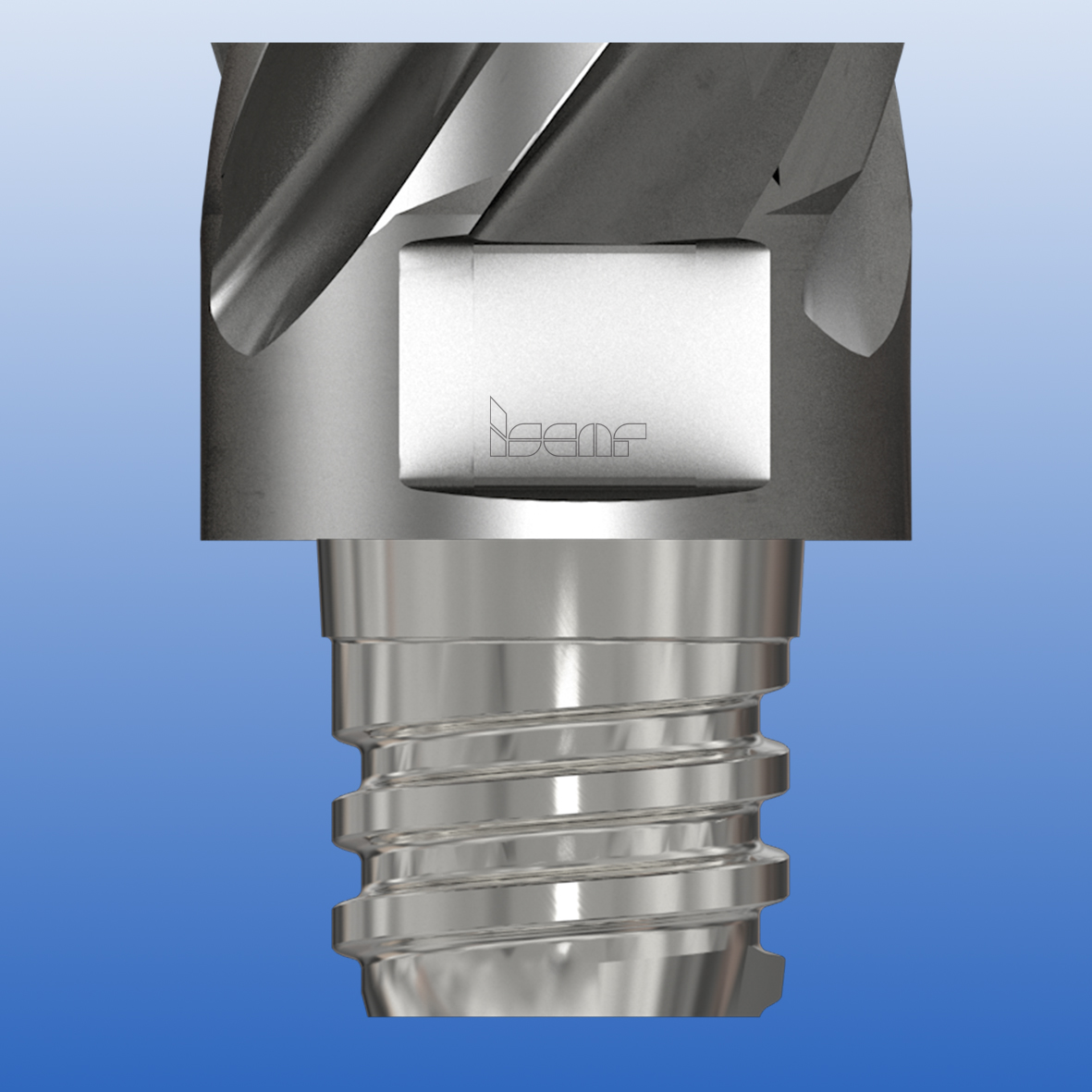

The above points make it problematic to use standard threads and strongly determine a special thread shape to comply with the specifications of the connection. Therefore, a thread connection as the head clamping element was highly questionable. Fortunately, the MULTI-MASTER, which is based on the threads of a specially designed profile (Fig.1), dismissed all doubts and its success led to a new look on common canons. Sometime after that, almost every tool manufacturer developed its own system for rotating tools with exchangeable threaded carbide heads.

Tools with threaded heads have significant advantages as they demonstrate impressive versatility, provide rational utilization of cemented carbide and are user-friendly with simple head replacement. It has been frequently asked what the secrets are of the MULTI-MASTER’s success and what are the features that ensure its popularity and longevity of the product.

Aside from the benefits outlined above, which are crucial for tools with exchangeable threaded heads, the MULTI-MASTER provides high dimensional repeatability with its face-contact design concept. This concept holds the "no setup" principle for replacing a worn head - no additional setup operations for adjustment are necessary and the head can be changed without removing the tool from the machine.

Another unique aspect of the MULTI-MASTER is its very wide variety of heads that cover a broad-spectrum of applications in milling, hole making, engraving, and gearing. In milling operations, these cover square shoulders, faces, 3D surfaces, chamfers, cavities and pockets, slots and grooves, threads, and machining by high-speed- and high-feed milling methods. And in Holemaking operations, center and spot drilling, countersinking, etc.

Combining two types of heads is a beneficial combination of two design approaches: fully ground heads from solid blanks and heads from pre-shaped sintered inserts. Together with a wide choice of shanks, adaptors, and reducers significantly simplifies the process of finding the best tool configuration for a variety of metal cutting operations. Apart from that, the line and its products are ideal for tailor-made products, which makes tool customization much easier. All of this turns the robust MULTI-MASTER line into a powerful tool for improving productivity and cutting production costs while ensuring longstanding customer commitment.

A new horizon of applications starts with ISCAR’s new thread size T12, intended for end milling heads with a 32 mm (1.25") diameter. Even though solid carbide endmills in this diameter are not common due to their high cost, there are industrial sectors, such as aerospace that need such tools.

Assemblies with exchangeable heads provide a much more cost-efficient solution and ISCAR is enthusiastic about its prospects of new developments. It’s important to note that among ISCAR’s introduced products, there are 5-flute endmill heads with variable helix that were designed specifically for machining difficult-to-cut titanium alloys and high temperature materials (ISO S group of application). The heads have a corner radius of 4 and 5 mm (.120", .250", .375"), which are typical for aircraft part production.

In the aerospace industry, the line was enhanced with 6-flute endmill heads in diameters of 8-25 mm (.315"-1.00") for machining titanium, including hard-to-cut β- and near β-alloys especially by the trochoidal milling method. The heads feature a combination of different helix and variable angular pitch to improve chatter stability.

A typical aircraft countersunk screw requires a 100°countersink. The same angle is often needed for riveting. The MULTI-MASTER provides an appropriate solution with its newly developed 2-flute countersink heads (Fig. 2) with 100°-point angle in diameters 9.525-19.05 mm (.375"-.750"). The heads are also suitable for chamfering and spot drilling.

The growth of 5-axis CNC machines has brought new efficient strategies for milling complex 3D shapes. This has increased the demands for cutting tools with a specific geometry, i.e., barrel endmills.

Following new needs, MULTI-MASTER replenished its range with appropriate heads that were successfully adopted by the customer, particularly in the aerospace, medical, and die and mold industries.

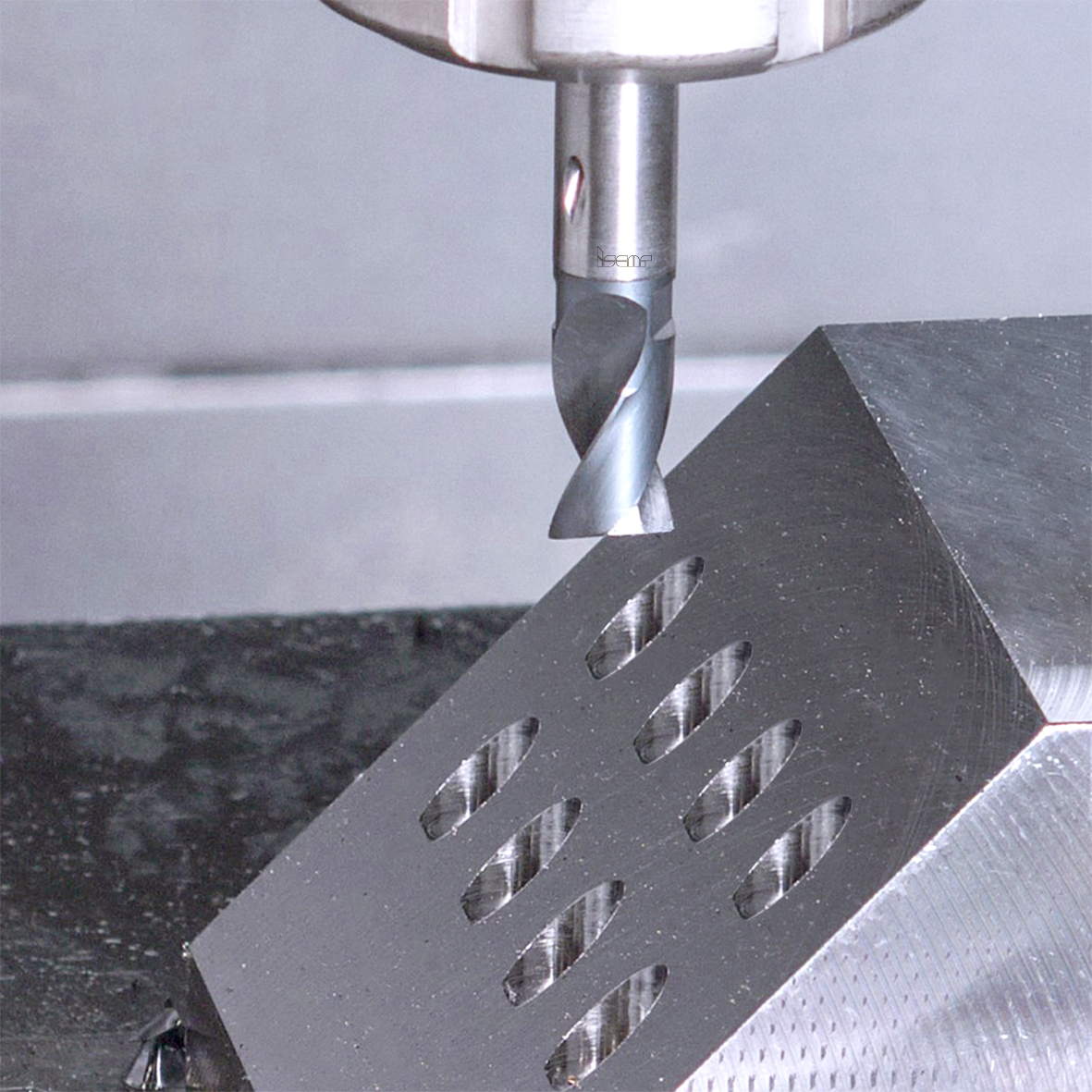

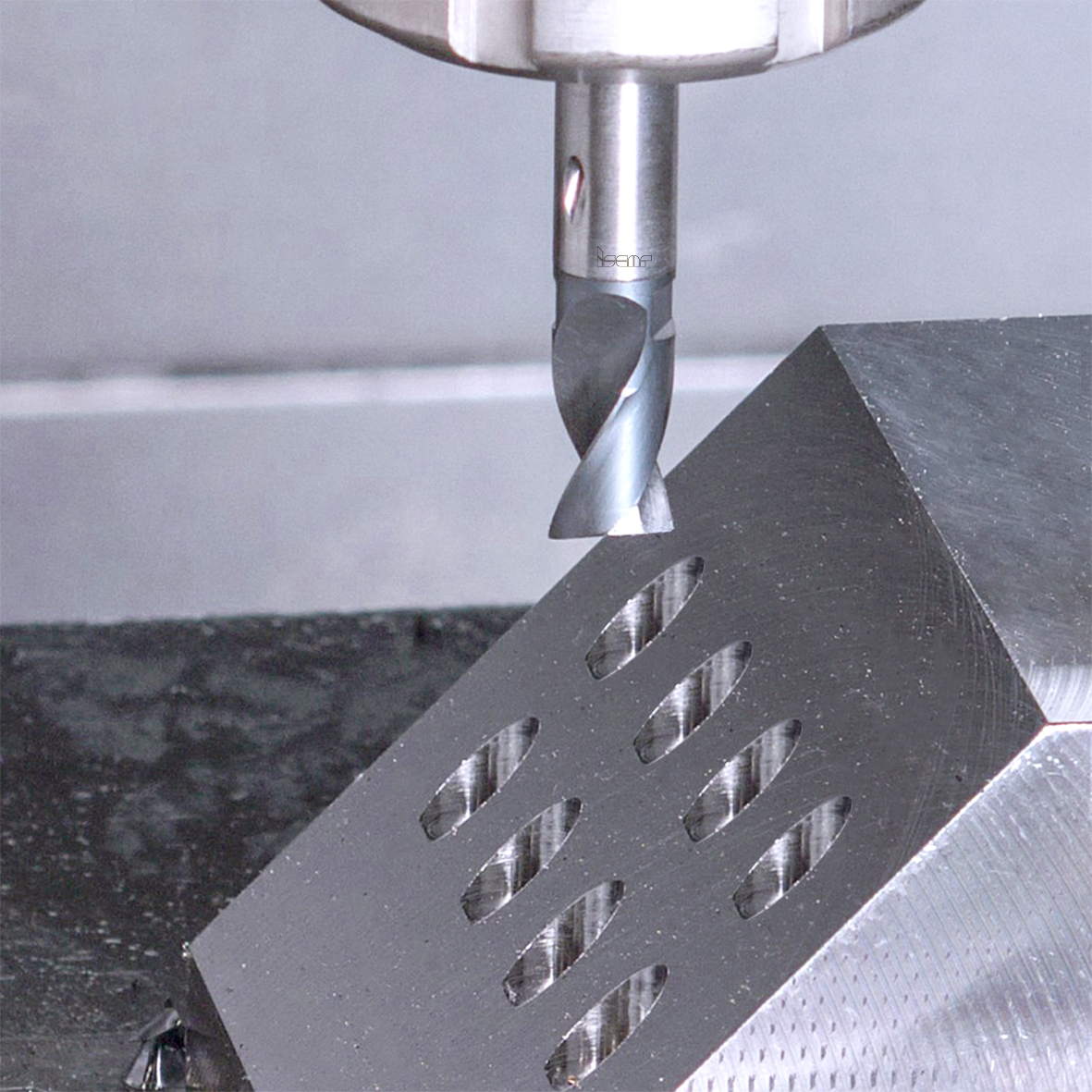

In hole making, the recently introduced precise flat bottom drilling heads have considerably expanded the line applicability in shallow drilling operations for steel, stainless steel, and cast iron (ISO P and K groups of application) including direct drilling inclined surfaces (Fig. 3). The head diameter tolerance meets the accuracy grade h7, while the head drilling capabilities extend up to 1.2 of the diameters.

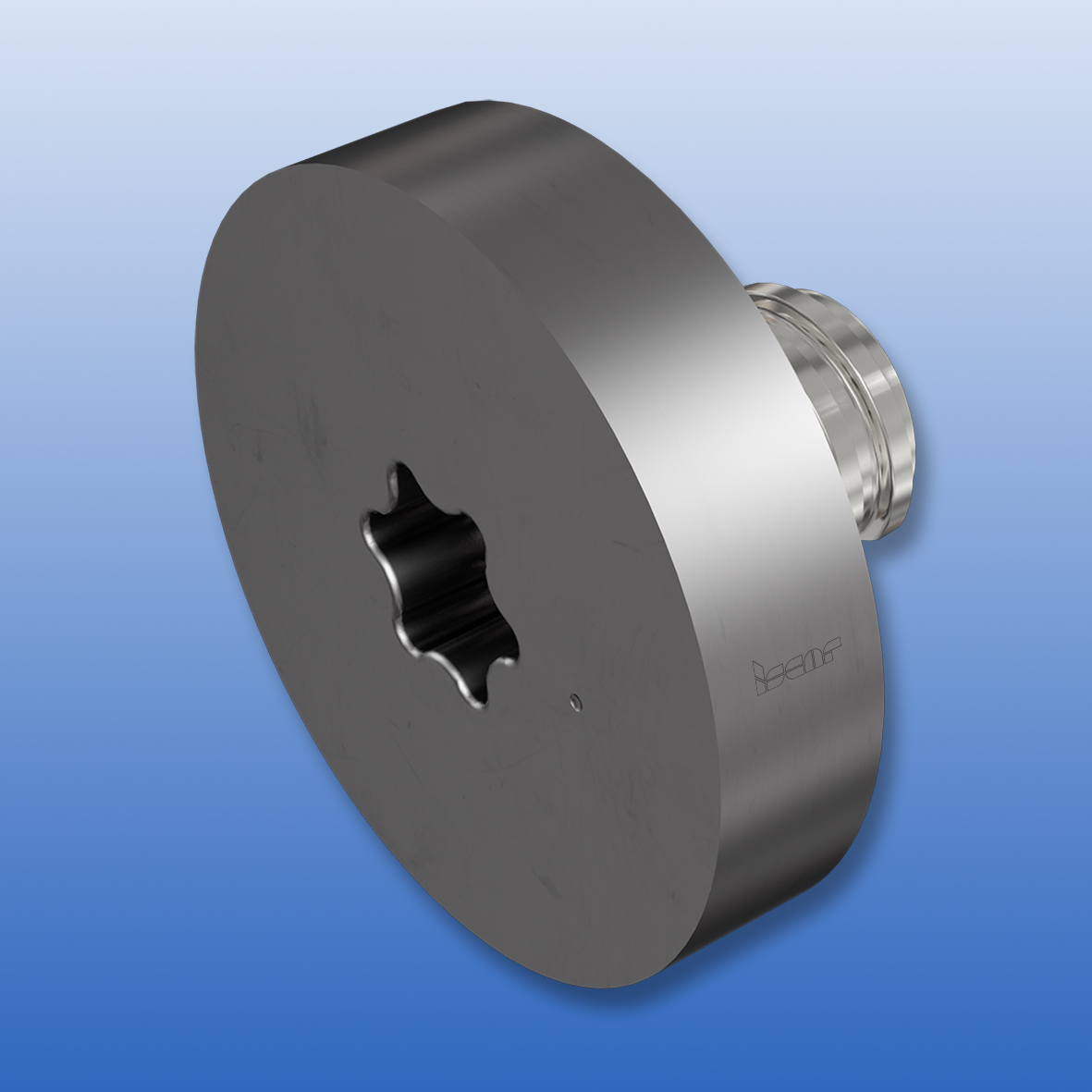

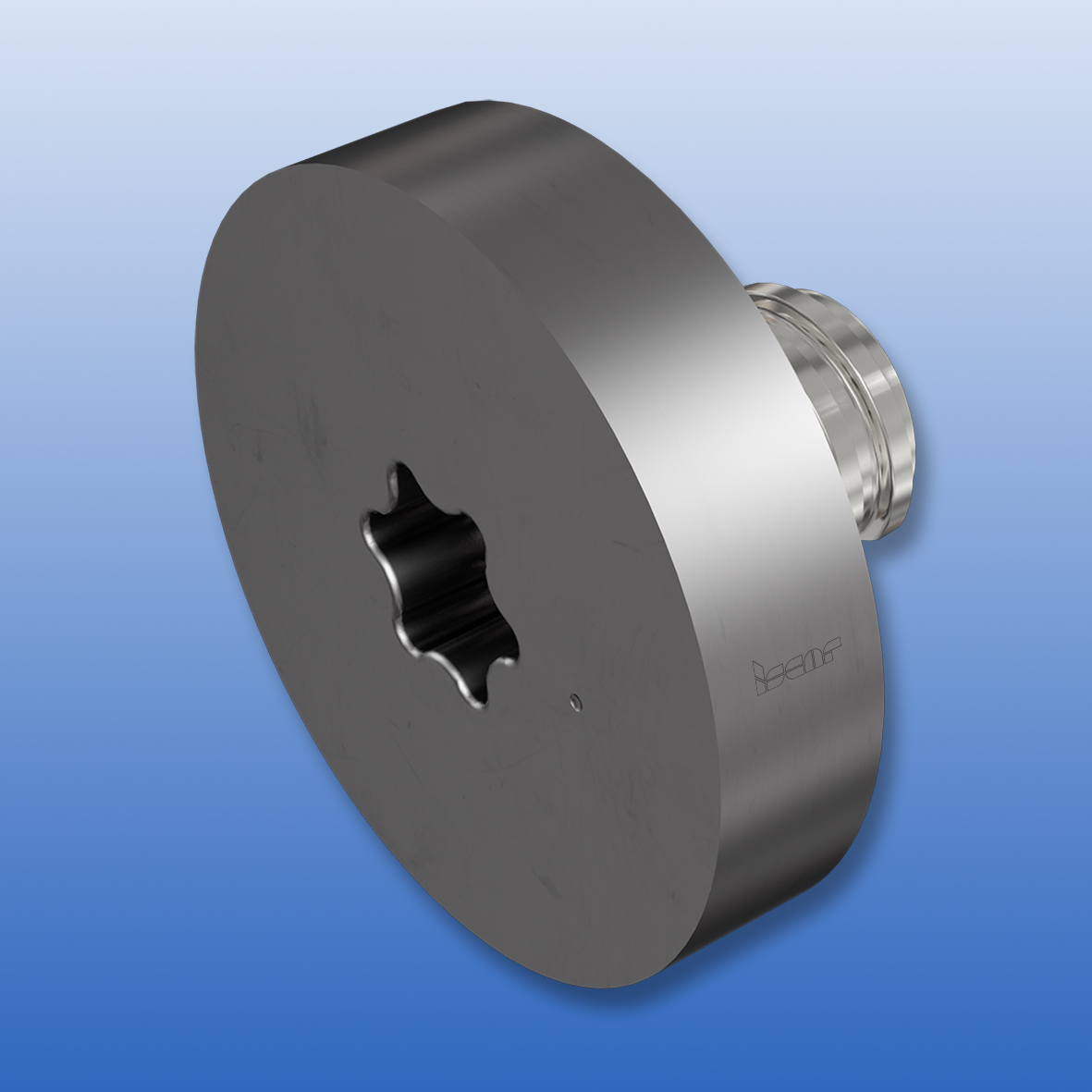

ISCAR’s motto “be more user- friendly” relates to the recent upgrade of the MULTI-MASTER groove milling head with a new clamping option. Incorporating a hexalobular TORX recess into a head design enables securing the head with ISCAR's fix- or adjustable torque wrenches for reliable clamping.

An advantage of the MULTI-MASTER is that the heads are excellent to produce special profiles. This line contains several threaded blanks from uncoated cemented carbides for tailor-made products. A short time ago the range of available blanks was expanded by disc-shape semi-finished heads (Fig. 4), which are successfully used for customized solutions in milling slots, grooves, threads, splines, and many more.

The above examples not only illustrate the development directions of one of the leading rotating tool systems with exchangeable carbide heads, but distinctly show that the sources for development and improvement of system capabilities are far from being exhausted.

The needs of modern manufacturing bring more and more requests and open new application fields that require an appropriate tooling response. The history of ISCAR’s MULTI-MASTER concludes with high versatility of tools with exchangeable heads and highlights their ability to meet growing industrial demands.

[Fig. 1- A special profile thread facilitates reliability and robustness of the MULTI-MASTER line.]

[Fig. 1- A special profile thread facilitates reliability and robustness of the MULTI-MASTER line.]

[Fig. 2- A 100°countersink head is commonly used in manufacturing aircraft parts.]

[Fig. 2- A 100°countersink head is commonly used in manufacturing aircraft parts.]

[Fig. 3- Efficient drilling inclined surfaces is not a problem for flat bottom heads.]

[Fig. 3- Efficient drilling inclined surfaces is not a problem for flat bottom heads.]

[Fig. 4- A disc-type blank head is ideal for customized solutions in milling slots and grooves. The hexalobular recess in a head face is intended for applying TORX-tipped wrenches with controlled torque for reliable clamping.]

[Fig. 4- A disc-type blank head is ideal for customized solutions in milling slots and grooves. The hexalobular recess in a head face is intended for applying TORX-tipped wrenches with controlled torque for reliable clamping.]