Page 7 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 7

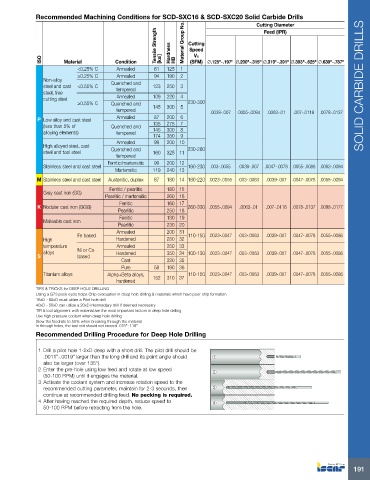

Recommended Machining Conditions for SCD-SXC16 & SCD-SXC20 Solid Carbide Drills

Cutting Diameter

Tensile Strength Material Group No. Cutting Feed (IPR)

Speed

Vc

ISO Material Condition [ksi] Hardness HB (SFM) Ø.125"-.197" Ø.200"-.315" Ø.319"-.391" Ø.393"-.625" Ø.630"-.787"

<0.25% C Annealed 61 125 1

≥0.25% C Annealed 94 190 2

Non-alloy Quenched and

steel and cast <0.55% C tempered 123 250 3 SOLID CARBIDE DRILLS

steel, free

cutting steel Annealed 109 220 4

≥0.55% C Quenched and 230-300

tempered 145 300 5 .0039-.007 .0055-.0094 .0063-.01 .007-.0118 .0078-.0137

P Low alloy and cast steel Annealed 87 200 6

(less than 5% of Quenched and 135 275 7

alloying elements) tempered 145 300 8

174 350 9

Annealed 99 200 10

High alloyed steel, cast

steel and tool steel Quenched and 160 325 11 230-280

tempered

Ferritic/martensitic 99 200 12

Stainless steel and cast steel 190-230 .003-.0055 .0039-.007 .0047-.0078 .0055-.0086 .0063-.0094

Martensitic 119 240 13

M Stainless steel and cast steel Austenitic, duplex 87 180 14 180-220 .0023-.0055 .003-.0063 .0039-.007 .0047-.0078 .0055-.0094

Ferritic / pearlitic 180 15

Gray cast iron (GG)

Pearlitic / martensitic 260 16

Ferritic 160 17

K Nodular cast iron (GGG) 260-330 .0055-.0094 .0063-.01 .007-.0118 .0078-.0137 .0098-.0177

Pearlitic 250 18

Ferritic 130 19

Malleable cast iron

Pearlitic 230 20

Annealed 200 31

Fe based 110-150 .0023-.0047 .003-.0063 .0039-.007 .0047-.0078 .0055-.0086

High Hardened 280 32

temperature Annealed 250 33

alloys Ni or Co Hardened 350 34 100-130 .0023-.0047 .003-.0063 .0039-.007 .0047-.0078 .0055-.0086

S based

Cast 320 35

Pure 58 190 36

Titanium alloys Alpha+Beta alloys, 110-150 .0023-.0047 .003-.0063 .0039-.007 .0047-.0078 .0055-.0086

hardened 152 310 37

TIPS & TRICKS for DEEP HOLE DRILLING

Using a G73 peck cycle helps Chip evacuation in deep hole drilling & materials which have poor chip formation

16xD - 50xD must utilize a Pilot hole drill

40xD - 50xD can utilize a 20xD intermediary drill if deemed necessary

TIR & tool alignment with material are the most important factors in deep hole drilling

Use high pressure coolant when deep hole drilling

Slow the feedrate to 50% when breaking through the material

In through holes, the tool exit should not exceed .078”-.118”.

Recommended Drilling Procedure for Deep Hole Drilling

1 Drill a pilot hole 1-2xD deep with a short drill. The pilot drill should be

.0011”-.0019” larger than the long drill and its point angle should 1

also be larger (over 135°).

2 Enter the pre-hole using low feed and rotate at low speed 2

(50-100 RPM) until it engages the material.

3 Activate the coolant system and increase rotation speed to the

recommended cutting parameter, maintain for 2-3 seconds, then 3

continue at recommended drilling feed. No pecking is required.

4 After having reached the required depth, reduce speed to 4

50-100 RPM before retracting from the hole.

191