Page 9 - HOLE_MAKING_CATALOG_INCH_2022_P373-P446

P. 9

USER GUIDE

REAMERS

ATTENTION: Cutting tools can break during use. b

To avoid injury always use safety precautions a

such as gloves, shields and eye protection.

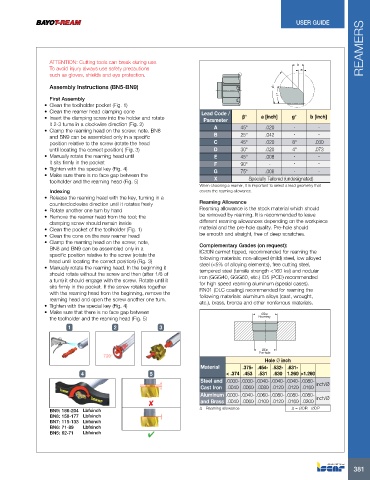

Assembly Instructions (BN5-BN9) β¡

γ¡

First Assembly

• Clean the toolholder pocket (Fig. 1)

• Clean the reamer head clamping cone Lead Code /

• Insert the clamping screw into the holder and rotate Parameter β° a [inch] g° b [inch]

it 2-3 turns in a clockwise direction (Fig. 2)

• Clamp the reaming head on the screw; note, BN8 A 45° .020 ־ ־

and BN9 can be assembled only in a specific B 25° .042 ־ ־

position relative to the screw (rotate the head C 45° .020 8° .030

until locating the correct position) (Fig. 3) D 30° .020 4° .073

• Manually rotate the reaming head until E 45° .008 ־ ־

it sits firmly in the pocket F 90° - ־ ־

• Tighten with the special key (Fig. 4) G 75° .006 ־ ־

• Make sure there is no face gap between the X

toolholder and the reaming head (Fig. 5) Specially Tailored (undesignated)

When choosing a reamer, it is important to select a lead geometry that

Indexing covers the reaming allowance.

• Release the reaming head with the key, turning in a

counterclockwise direction until it rotates freely Reaming Allowance

• Rotate another one turn by hand Reaming allowance is the stock material which should

• Remove the reamer head from the tool; the be removed by reaming. It is recommended to leave

clamping screw should remain inside different reaming allowances depending on the workpiece

• Clean the pocket of the toolholder (Fig. 1) material and the pre-hole quality. Pre-hole should

• Clean the cone on the new reamer head be smooth and straight, free of deep scratches.

• Clamp the reaming head on the screw; note,

BN8 and BN9 can be assembled only in a Complementary Grades (on request):

IC30N cermet tipped, recommended for reaming the

specific position relative to the screw (rotate the

head until locating the correct position) (Fig. 3) following materials: non-alloyed (mild) steel, low alloyed

• Manually rotate the reaming head. In the beginning it steel (<5% of alloying elements), free cutting steel,

should rotate without the screw and then (after 1/6 of tempered steel (tensile strength <160 ksi) and nodular

iron (GGG40, GGG60, etc.) ID5 (PCD) recommended

a turn) it should engage with the screw. Rotate until it

sits firmly in the pocket. If the screw rotates together for high speed reaming aluminum (special cases).

RN01 (DLC coating) recommended for reaming the

with the reaming head from the beginning, remove the

reaming head and open the screw another one turn. following materials: aluminum alloys (cast, wrought,

• Tighten with the special key (Fig. 4) etc.), brass, bronze and other nonferrous materials.

• Make sure that there is no face gap between ØDR

the toolholder and the reaming head (Fig. 5) Reaming

1 2 3

ØDP

Pre-hole

Hole Ø inch

Material .375- .454- .532- .631-

4 5 < .374 .453 .531 .630 1.260 >1.260

Steel and .0030- .0030- .0040- .0040- .0040- .0080-

Cast Iron .0040 .0060 .0080 .0120 .0120 .0160 inch/Ø

Aluminum .0030- .0040- .0060- .0080- .0080- .0080-

and Brass .0040 .0060 .0100 .0120 .0160 .0200 inch/Ø

BN9: 186-204 Lbfxinch Δ - Reaming allowance Δ = ∅DR - ∅DP

BN8: 150-177 Lbfxinch

BN7: 115-133 Lbfxinch

BN6: 71-89 Lbfxinch

BN5: 62-71 Lbfxinch

381