Page 12 - MILLING_CATALOG_INCH_2022_P361-P592

P. 12

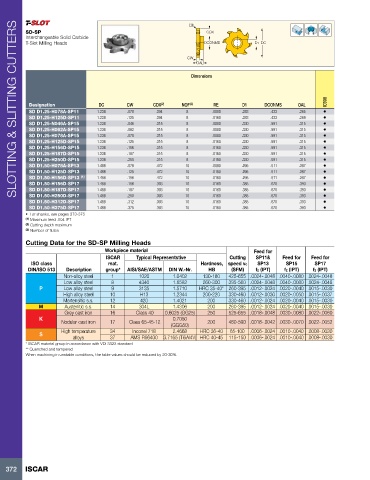

SLOTTING & SLITTING CUTTERS

RE

SD-SP CDX

Interchangeable Solid Carbide

T-Slot Milling Heads DCONMS D1 DC

CW

OAL

Dimensions

IC908

Designation DC CW CDX (2) NOF (3) RE D1 DCONMS OAL

SD D1.25-H078A-SP11 1.238 .078 .394 8 .0080 .283 .433 .265 •

SD D1.25-H125D-SP11 1.238 .125 .394 8 .0160 .283 .433 .269 •

SD D1.25-N046A-SP15 1.238 .046 .315 8 .0080 .330 .591 .315 •

SD D1.25-H062A-SP15 1.238 .062 .315 8 .0080 .330 .591 .315 •

SD D1.25-H078A-SP15 1.238 .078 .315 8 .0080 .330 .591 .315 •

SD D1.25-H125D-SP15 1.238 .125 .315 8 .0160 .330 .591 .315 •

SD D1.25-H156D-SP15 1.238 .156 .315 8 .0160 .330 .591 .315 •

SD D1.25-H187D-SP15 1.238 .187 .315 8 .0160 .330 .591 .315 •

SD D1.25-H250D-SP15 1.238 .250 .315 8 .0160 .330 .591 .315 •

SD D1.50-H078A-SP13 1.488 .078 .472 10 .0080 .295 .511 .287 •

SD D1.50-H125D-SP13 1.488 .125 .472 10 .0160 .295 .511 .287 •

SD D1.50-H156D-SP13 (1) 1.488 .156 .472 10 .0160 .295 .511 .287 •

SD D1.50-H156D-SP17 1.488 .156 .393 10 .0160 .385 .670 .393 •

SD D1.50-H187D-SP17 1.488 .187 .393 10 .0160 .385 .670 .393 •

SD D1.50-H250D-SP17 1.488 .250 .393 10 .0160 .385 .670 .393 •

SD D1.50-H312D-SP17 1.488 .312 .393 10 .0160 .385 .670 .393 •

SD D1.50-H375D-SP17 1.488 .375 .393 10 .0160 .385 .670 .393 •

• For shanks, see pages 373-375

(1) Maximum feed .004 IPT

(2) Cutting depth maximum

(3) Number of flutes

Cutting Data for the SD-SP Milling Heads

Workpiece material Feed for

ISCAR Typical Representstive Cutting SP11& Feed for Feed for

ISO class mat. Hardness, speed vc SP13 SP15 SP17

DIN/ISO 513 Description group* AISI/SAE/ASTM DIN W.-Nr. HB (SFM) fz (IPT) fz (IPT) fz (IPT)

Non-alloy steel 1 1020 1.0402 130-180 425-655 .0024-.0048 .0040-.0080 .0024-.0048

Low alloy steel 8 4340 1.6582 260-300 395-560 .0024-.0048 .0040-.0080 .0024-.0048

P Low alloy steel 9 3135 1.5710 HRC 35-40* 260-395 .0012-.0024 .0020-.0040 .0015-.0030

High alloy steel 10 H13 1.2344 200-220 330-460 .0012-.0030 .0020-.0050 .0015-.0037

Martensitic s.s. 12 420 1.4021 200 330-460 .0012-.0024 .0020-.0040 .0015-.0030

M Austenitic s.s. 14 304L 1.4306 200 260-395 .0012-.0024 .0020-.0040 .0015-.0030

Grey cast iron 16 Class 40 0.6025 (GG25) 250 525-655 .0018-.0048 .0030-.0080 .0022-.0060

K 0.7050

Nodular cast iron 17 Class 65-45-12 200 460-590 .0018-.0042 .0030-.0070 .0022-.0052

(GGG50)

High temperature 34 Inconel 718 2.4668 HRC 36-40 65-100 .0006-.0024 .0010-.0040 .0008-.0030

S

alloys 37 AMS R56400 3.7165 (Ti6Al4V) HRC 40-45 115-150 .0006-.0024 .0010-.0040 .0008-.0030

* ISCAR material group in accordance with VDI 3323 standard

** Quenched and tempered

When machining in unstable conditions, the table values should be reduced by 20-30%.

372 ISCAR